Less than six months after opening, Wallwork Heat Treatment’s Hot Isostatic Pressin (HIP) center is preparing to receive a second HIP system from Quintus Technologies.

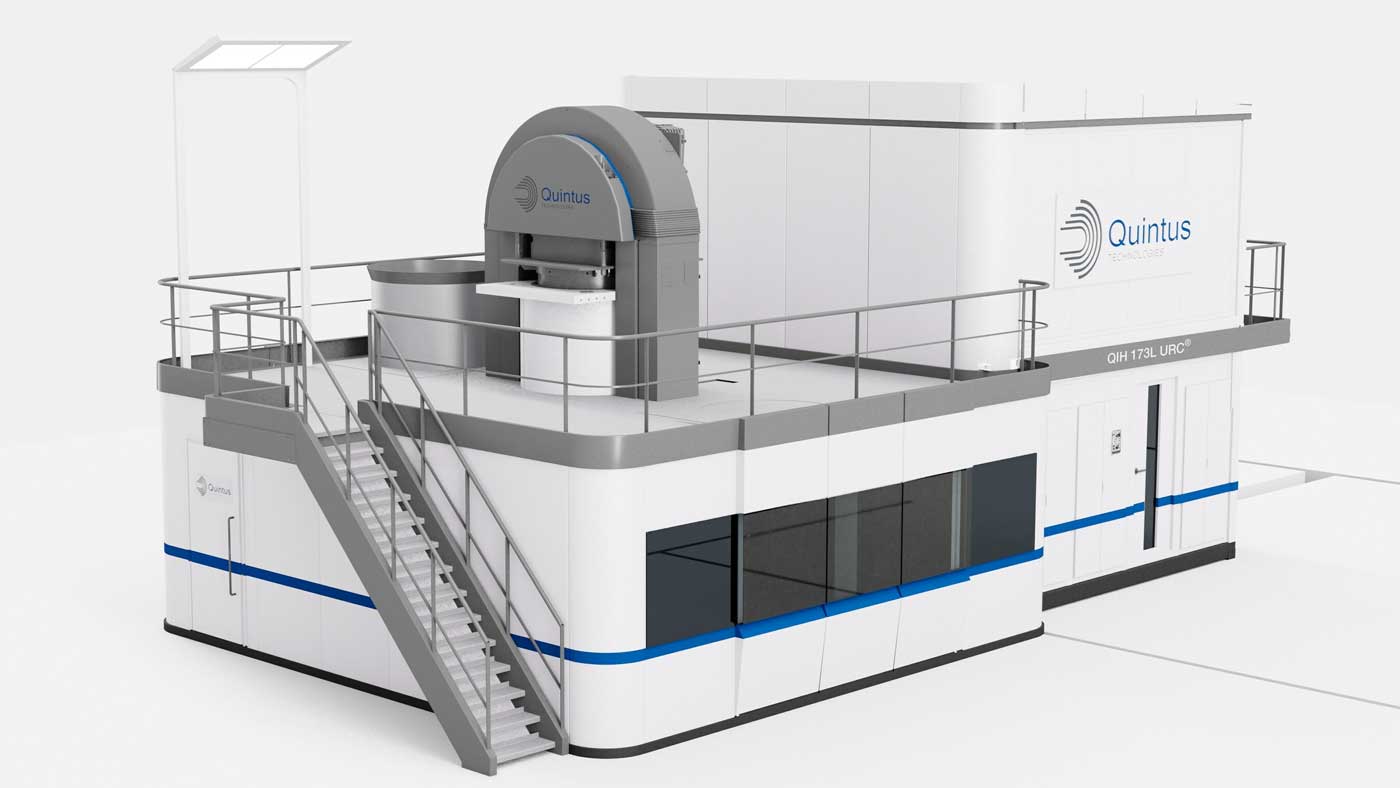

Increased demand for expanded thermal processing capabilities led to the order of a second press, the model QIH 173L M URC, identical to the model that inaugurated the center in September 2023.

Hot Isostatic Pressing is crucial for the production of metal powder-based parts in 3D printing.

“With a track record in providing our previous unit, it made sense to once again work with Quintus in this next phase of our HIP journey,” says Simeon Collins, Wallwork Holdings. The emergence of more technically challenging and higher pressure cycles bolstered the decision. “Their knowledge and experience, plus their worldwide Quintus Care support program, gives Wallwork and our customers the confidence to develop and grow long-term relationships and quality service. We see exponential growth for the units over the short term.”

This process is often the only way to achieve the high material uniformity required for mission-critical applications. The QIH 173L achieves 100% of the maximum theoretical material density and produces components with improved fatigue properties, ductility, structural integrity and fracture toughness.

The HIP center in Bury, North Manchester, UK, was built on a 2500 m² site with the aim of expansion. The decision to purchase a second press from Quintus was based on the success of the first system.

“Wallwork is a privately owned heat treatment company with four sites in the UK,” says Mr. Collins. “Many of our customers–component manufacturers within diverse industrial segments—no longer want to deal with the complication of multisite and multicompany subcontracting, as well as logistic management. With our HIP systems, the full package of processing capability and capacity is now available with one phone call or email.”

Equipped with Quintus’ proprietary Uniform Rapid Cooling (URC) technology, the QIH 173L system provides excellent temperature uniformity, which is crucial for improving the mechanical properties of the final product. The system offers full digital connectivity, allowing greater control over the production process and finished products.

The partnership with Quintus Technologies and the investment in future-oriented technologies illustrates Wallwork’s commitment to a comprehensive range of services and the promotion of additive manufacturing.

“We are doubly pleased to be working with Wallwork,” comments Jan Söderström, CEO of Quintus Technologies. “Our mutal focus on customer-driven problem solving and long-term supplier partnerships have engendered a strong commitment to success. We look forward to installing the press in mid-2025 as Wallwork continues to invest in all areas of the business to support its comprehensive service offering,” Mr. Söderström concludes.

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.