Desktop Health announced a breakthrough in bioprinting with the launch of PrintRoll, an innovative rotating build platform that can produce intelligent tubular solutions for the body’s vascular, digestive, respiratory, and reproductive channels on the 3D-Bioplotter premier bioprinting system.

The 3D-Bioplotter is a highly sophisticated extrusion-based 3D printer that processes liquids, melts, pastes, gels, or other materials, including cells, through a needle tip on a Swiss-made, 3-axis gantry system with high accuracy and temperature, sterility, and design controls. 3D-Bioplotter offers eight printheads with the widest range of temperatures in bioprinting — from 2°C to 500°C (35.6°F to 932°F) — enabling complex, multi-material medical parts.

The PrintRoll add-on feature has been in development since 2019 as part of a collaboration with Johannes Gutenberg University Mainz, a public research university in Mainz, Germany.

“We are proud to offer the first bioprinting tool specifically designed to develop medical solutions for the thousands of miles of channels found in the human body,” said Ric Fulop, Founder and CEO of Desktop Metal. “Desktop Health exists to deliver 3D printing solutions that improve patient lives, and we are confident that PrintRoll, offered exclusively on the 3D-Bioplotter, will enable all-new regenerative innovations. We look forward to seeing what our customers will create next with this exciting new tool.”

How PrintRoll Works

The PrintRoll platform attaches to the modular build plate of the 3D-Bioplotter and features a motor-driven rotating mandrel with spring-loaded, easily exchangeable drums of different sizes. Rotating speed is tightly controlled by the 3D-Bioplotter’s easy-to-use software.

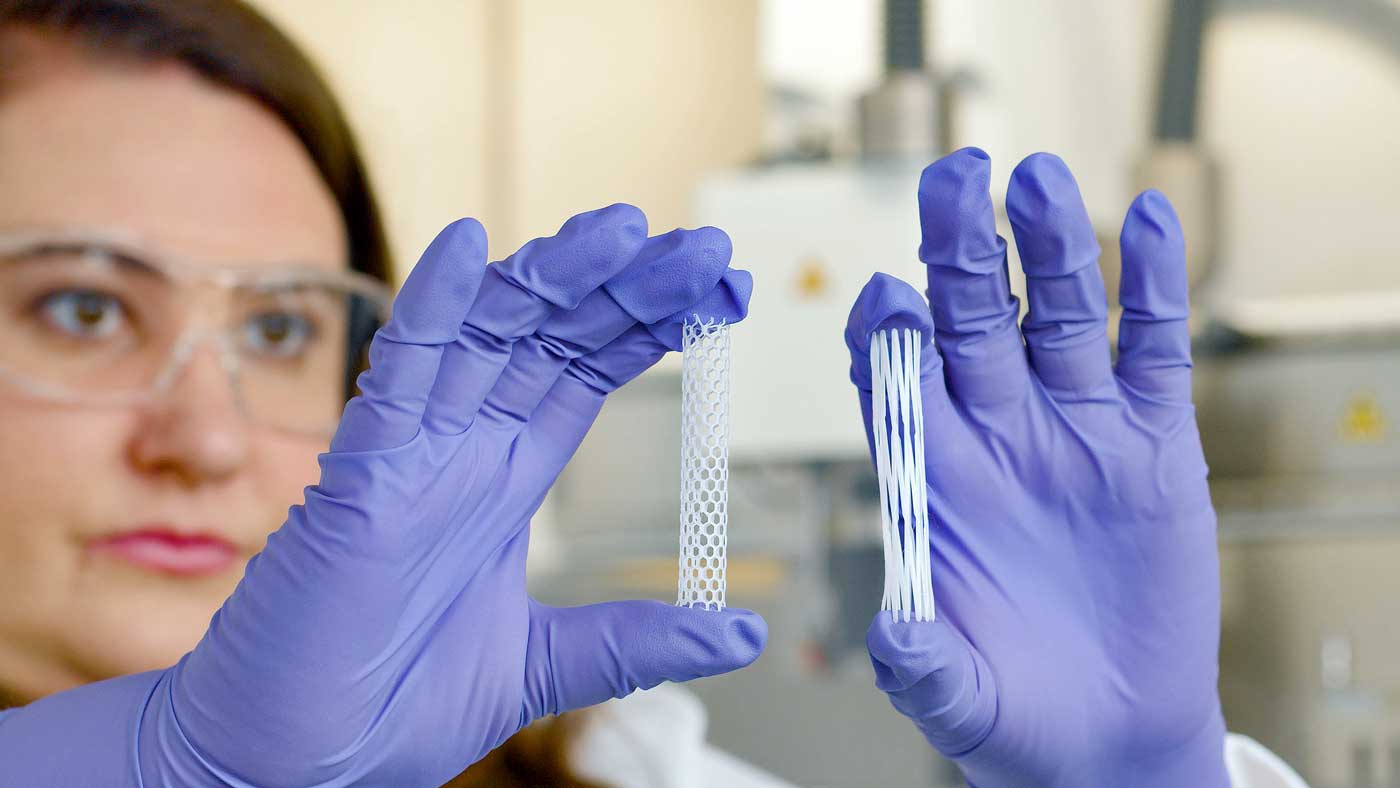

As the PrintRoll tool rotates, the printhead moves back and forth depositing material on the surface in the desired design. For example, polycaprolactone (PCL), a medical-grade, biodegradable plastic used in many FDA-cleared implants and devices, hardens quickly on the drum after the melted material is printed. In bioprinting, users typically produce a structure or scaffold in a stiff or flexible biocompatible material that is designed to repair and integrate with cells of the body, sometimes degrading after a certain period of time.

The PrintRoll comes with a 10 mm diameter drum – with 20 mm and 40 mm sizes available – designed to accommodate the development of solutions for a variety of human channels, which vary based on age and gender. Standard diameter sizes generally correspond to the diameters of the femoral artery (~10 mm), trachea (~10-20 mm), fallopian tube (~5-15 mm), aorta (~25 mm) esophagus (~30 mm), and a range of intestine segments (~40-100 mm).

The PrintRoll system supports printing hollow cylindrical structures up to 140 mm in length, depending on the printhead used. Custom sizes may also be available.

“Up until now, the creation of thin-walled cylindrical devices with complex structured walls has been challenging to accomplish with regenerative materials, such as hydrogels,” said Nicole Black, Ph.D., VP of Biomaterials and Innovation at Desktop Health. “With the PrintRoll, materials are patterned directly on top of a substrate that rolls as the printhead also moves, supporting the deposited layers and therefore expanding the palette of materials that can be 3D printed into these important structures. Following printing, devices can be removed from the PrintRoll, leaving high-resolution and reproducible parts that customers have come to expect from the 3D-Bioplotter.”

The PrintRoll comes with a library of honeycomb designs and standard printing parameters for common materials. The PrintRoll platform, which is compatible with 4th Generation 3D-Bioplotter models, is available for pre-order now, with shipping expected in the fourth quarter.

3D-Bioplotter Continues Pioneering Bioprinting

PrintRoll continues the long history of bioprinting innovations on the world’s most researched bioprinting system, as detailed in the last 3D-Bioplotter brochure.

This tradition is also continued with CMFlex — the first 3D printed regenerative bone graft substitute product cleared by the FDA and the first such clearance based on manufacturing on the 3D-Bioplotter. Developed by Dimension Inx, CMFlex is an easy-to-use flexible bone graft product that is 3D printed on a standard 3D-Bioplotter Manufacturer model. This new product is an alternative to an autograft, in which a physician intrusively harvests bone from one area of a patient’s body to repair damaged or diseased bone elsewhere in the body.

“The recent FDA clearance of CMFlex by Dimension Inx is a breakthrough for the field of additive, regenerative medicine – one that clearly showcases the robustness of the 3D-Bioplotter,” said Lou Azzarra, President of Desktop Health. “Commercial milestones like this often take many years, and we congratulate the entire team at Dimension Inx on this achievement.”

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.