Sure, of course – possible and intended!

What has been a great scandal in Archimedes times and had him inspired to his “bathtub-method”, is nowadays the expression of the highest standard of technological development.

With the InssTek 3D metal printer it is indeed possible to print a complex metal structure out of various types of metals in a single build-up process! For example to print the inner core part out of cheap material, but the surface with specifically designed high-tech alloys. Although this might seem to ease the handcraft for fraudsters and bunglers, the actual purpose of this technology is to increase industrial effectiveness to the maximum.

The goal for this kind of application is to make targeted use of different kind of metal properties. A tidal power plant turbine part, for example, could be produced economically out of common steel and afterwards coated with a few millimeter thick layer of chrome-nickel-alloy. In this way the part can be made corrosion resistant against seawater, without being produced entirely out of the expensive alloys. Another possible application would be an injection mould, with its contact surface being made out of high-tensile tool steel for better wear resistance, but its body out of copper alloy for fast heat dissipation to enable shorter cycle time. These are just a few examples from a variety of many individual applications.

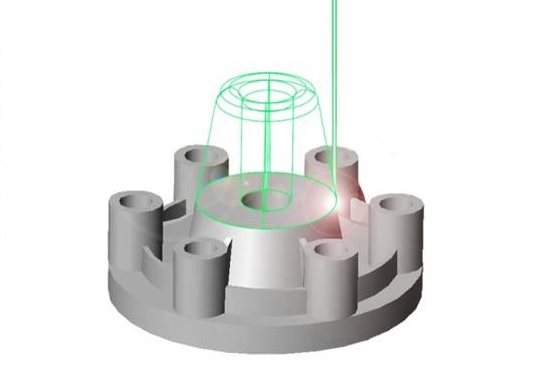

All this is possible thanks to InssTek’s proprietary “directed energy deposition” based DMT technology, which needs no vacuum- or inert gas chamber and flat surfaces. In this process, the metal powder and the inert gas flow simultaneously out of the freely movable laser head. By using a tilting and rotation table as work platform, there are almost no limitations of structures or sizes.

The standard version features three metal powder hoppers with a capacity of 3kg each. These hoppers can be filled with different types of metal powders. The powders will flow either one after another or simultaneously in the desired ratio out of different hoppers.

The South Korean company InssTek Inc., which has been in research and development of this technology already since 1993, optimised this procedure to such an extent, that not just metal powder but even artificial diamond powder can be printed. This technology is currently used to make special metal cutting tools with a diamond-copper-alloy. With our current standard modules the minimum printable layer thickness is less than 150µm with a surface roughness of Ra10.

Application example: A mould entirely made from quenched and tempered steel for fuel-efficient 3-cylinder engines is being coated with a 4mm thin layer of Hastelloy.

Would you like to contribute a guest post as well? Please contact us!

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.