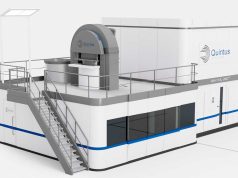

Quickparts, the specialist in on-demand custom parts manufacturing for 3D printing and traditional manufacturing, announces that it has become a Foundation Partner with Nexa3D, the maker of professional and industrial polymer 3D printers, on Nexa3D’s Quantum Laser Sintering (QLS) platform, the QLS 820.

“We are thrilled to be the first on-demand manufacturing service provider to experience the benefits of higher throughput, thermoplastic, additive manufacturing,” said Ziad Abou, CEO, Quickparts. “We pride ourselves on offering quick-turn manufacturing services to our customers and look forward to introducing an even faster and more economical production of higher volume thermoplastic components with Nexa3D’s QLS 820.”

The QLS 820 represents powder-bed technology that combines fast printing times with open materials and a cloud software platform to deliver greater production volumes. It also offers a greater material selection for customers, giving them access to materials such as PA 12, polypropylene, PBT, aluminum, glass, fiber-filled plastics, and more. The system offers continuous production during the cooldown process, which can help eliminate bottlenecks and speed up production times.

The QLS 820 system offers:

- Faster turn times for SLS projects

- Higher throughput & large build volume

- Greater material options, including high-temperature materials and processing

- Automation-ready, easy-to-use, technology-agnostic software platform

“We founded Nexa3D to digitize supply chains sustainably by making polymer 3D printers affordable for professionals and businesses of all sizes,” said Avi Reichental, co-founder, and CEO, Nexa3D. “We are proud that our new QLS 820 delivers productivity gains without extensive costs and lead times.”

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.