At this year’s JEC World, a trade fair for composite materials, the Japanese company Toray Engineering will be presenting new solutions for the efficient processing of carbon fiber-reinforced plastics at stand 6S96 at the Paris Nord Villepinte Exhibition Center from 5 to 7 March.

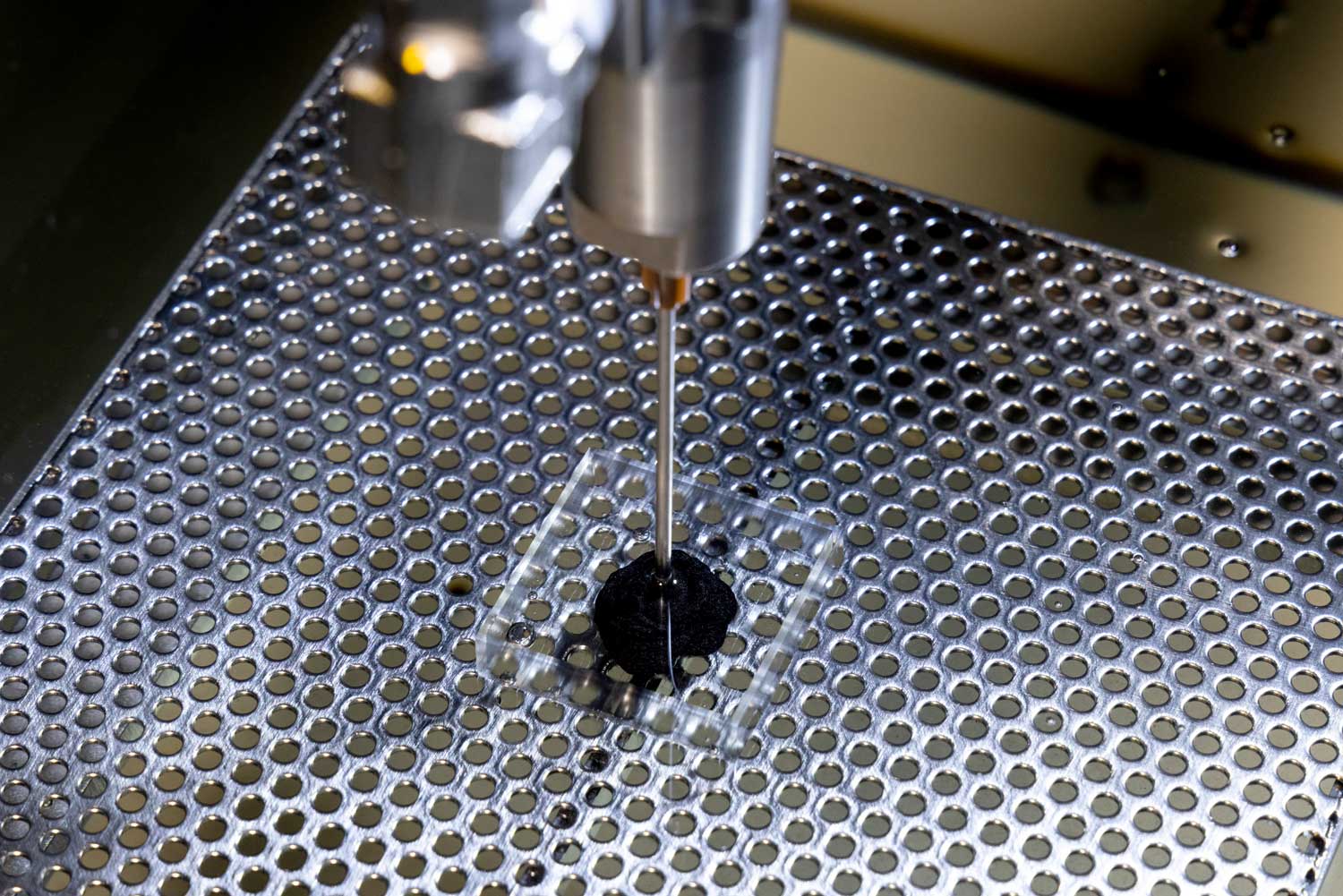

The focus will be on the presentation of the 3D printing system “Core Shell Composite Material 3D Molding Machine”. The “core shell method” is an innovative three-dimensional molding process that improves the properties of workpieces made from carbon fiber-reinforced resin.

The second machine at the booth is an AFP/ATL (Automated Fiber Placement / Automated Tape Layup) 3D molding machine with a pneumatically controlled parallel guide mechanism. Toray Engineering will also be presenting the 3D TIMON – CompositePRESS analysis software, which simulates the flow and fiber behavior during compression molding.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.