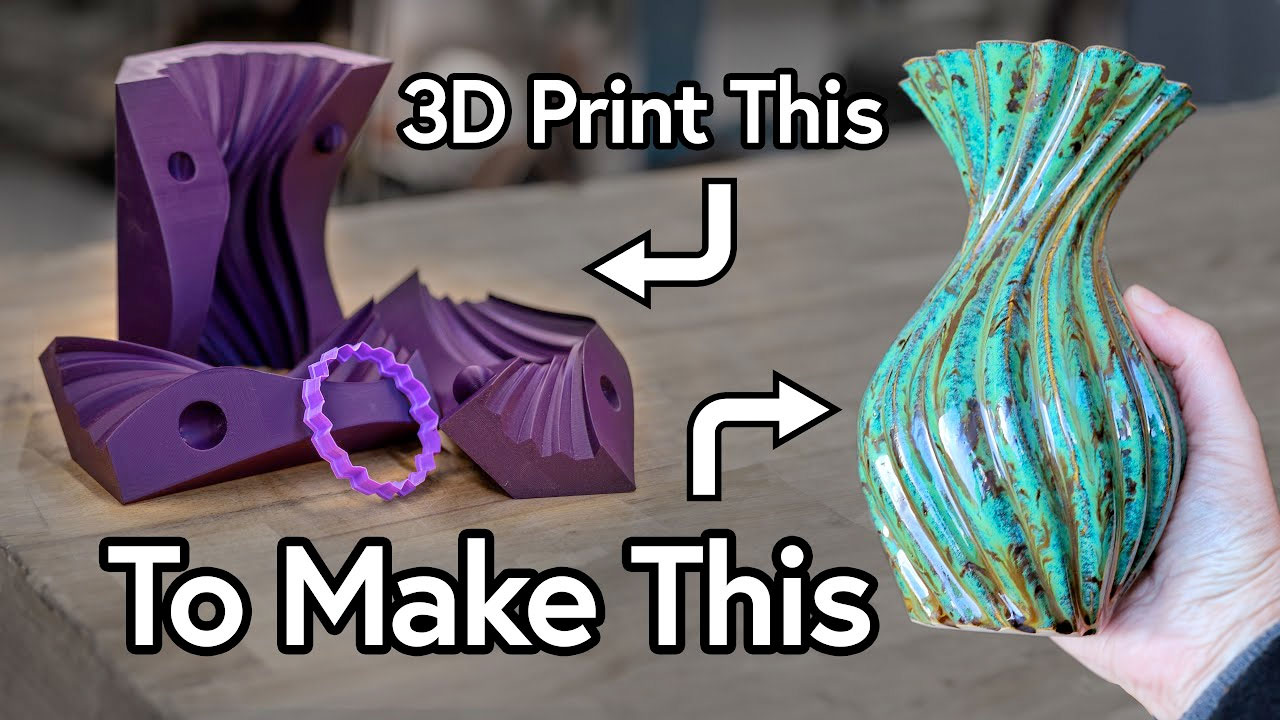

YouTube creator Allie Katz has presented a method of combining 3D printing and ceramics. Katz presents “slab casting” – an alternative to slab casting, which can be time-consuming.

The creator’s method uses 3D-printed molds to produce ceramics. By combining the possibilities of 3D printing to produce intricate designs and the malleability of clay, a range of possibilities arise.

In the video, Allie Katz shows in detail how basic shapes and cutting templates are first modeled digitally. Starting with a positive CAD design, the molds were designed to avoid undercuts and allow air to enter, as a plastic mold cannot suck the water out of the clay like a plaster mold. Some plasticine cookie cutters were also designed to help with the trickier parts of the geometry. Once everything was printed, the molds were coated with cornstarch and the clay pressed into them. This is followed by the usual firing process.

According to Katz, the combination of digital design and manual working of the clay allows for very complex geometric structures that would be almost impossible to create by hand.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.