The days when only enthusiasts at home printed 3-dimensional on self-built “RepRaps” are over. For relatively little money from 500 Euros you can afford a 3D-printer.

Unfortunately, one has yet to acquire some knowledge in order to come to useful results with the clever machine.

You have to adjust a lot in the more than 20 different print settings:

• Layer thickness, speed, Retract!

• Filling %, number of Perimeters , track width etc.

To cope with these parameter settings intensive incorporation in the matter is needed, or one is satisfied with processing profiles which are included by the providers of the printers. However, first questions arise when you want to print a complicated object with a more exotic material.

What temperature should I set? I only would like to print a thin-walled vase and it is to be done as quickly as possible.

Here some experience is necessary and it takes time to acquire it.

3D-printers can be designed much more comfortable if only the printhead design would be adapted to today’s technical possibilities.

Many printheads, i.e. where the filament is melted like a mobile hot-melt gun, namely still are from yesterday, technically seen.

In these printheads you often can not melt all available materials to good printing results, sometimes the hotend is clogged, or the hot melt is conveyed pulsating, which in turn does not look good at printing object.

More User-friendly, quasi Plug and Print, just for beginners, what does that mean in detail?

- The printer detects which filament you put in the printer,

- all important print settings such as optimum temperature, head speed, material flow etc. calculates the software,

- also it does not matter which filament is used: whether ABS, PLA, PET, or those with natural fillers (wood, silk, lime),

- even the desired surface finish could be set, for example, smooth, rough, karst

- The software prevents settings which can lead to blockages in the nozzle.

- and also detects whether your material has absorbed through poor storage too much moisture.

- suitable for filaments of the future 🙂

Recognizing filaments, how does it work?

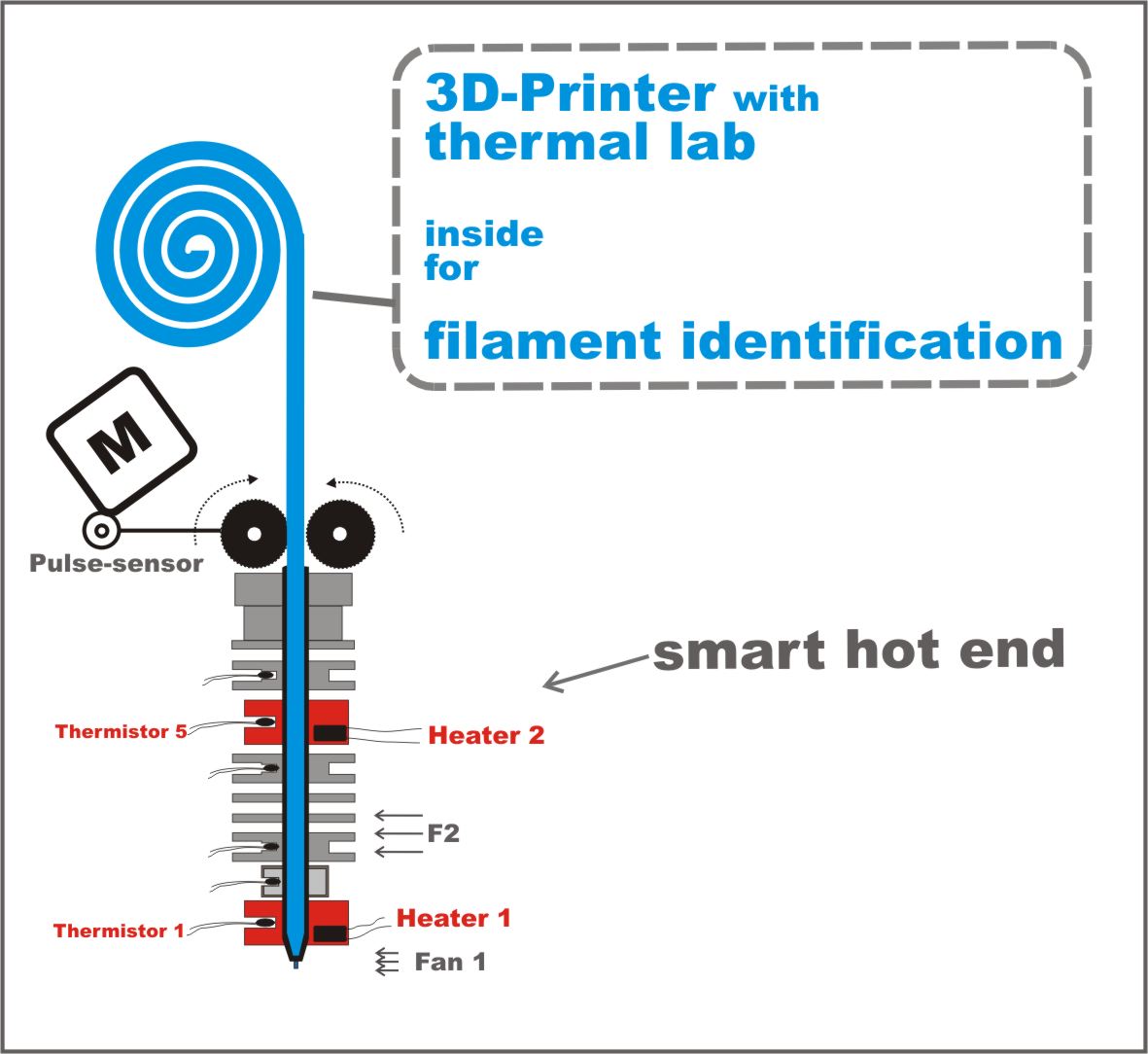

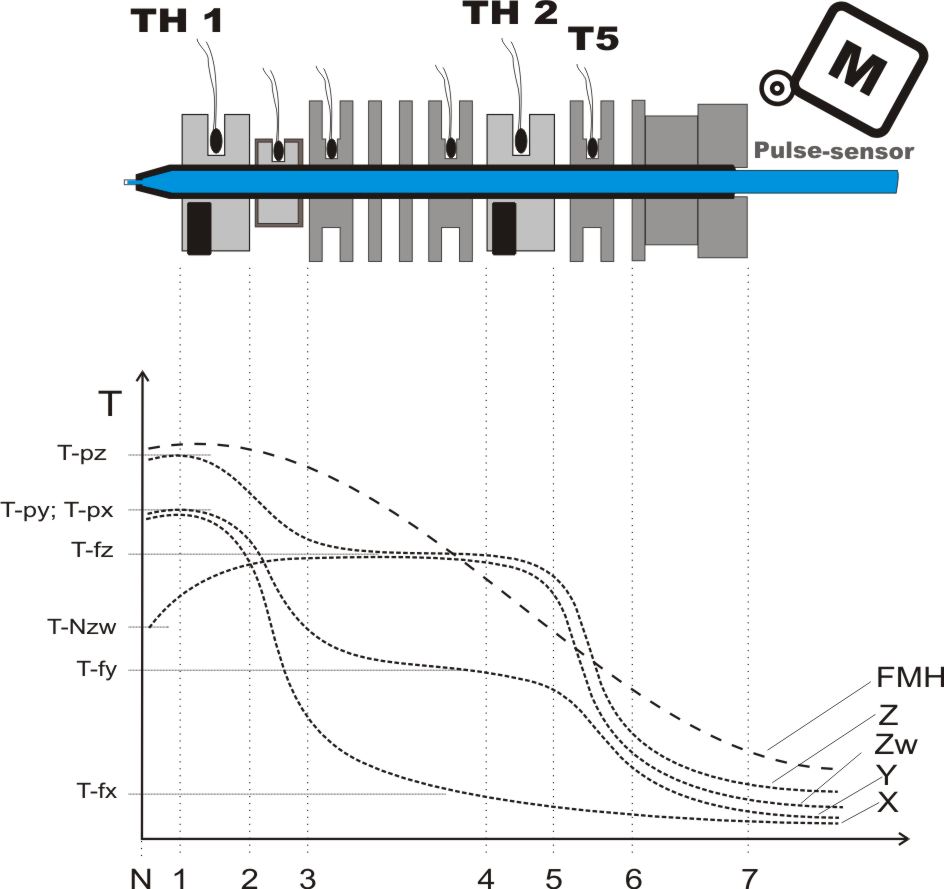

The printhead in conjunction with the software functions as a small thermal analysis-laboratory, which characterizes the melt of the filament-resin in terms of its viscosity in the melted state.

The main component is the recognition of the actual physical pressure within the melt chamber by a force-measuring sensor in cooperation with several heating and cooling zones along the filament channel.

The measured values are compared in a database within the printer software (or the slicing program) with predefined data and converted to optimum print parameters.

The database can be updated by data from the filament producers, but also the data your printer has found out of a new filament can be provided to the community.

My goal?

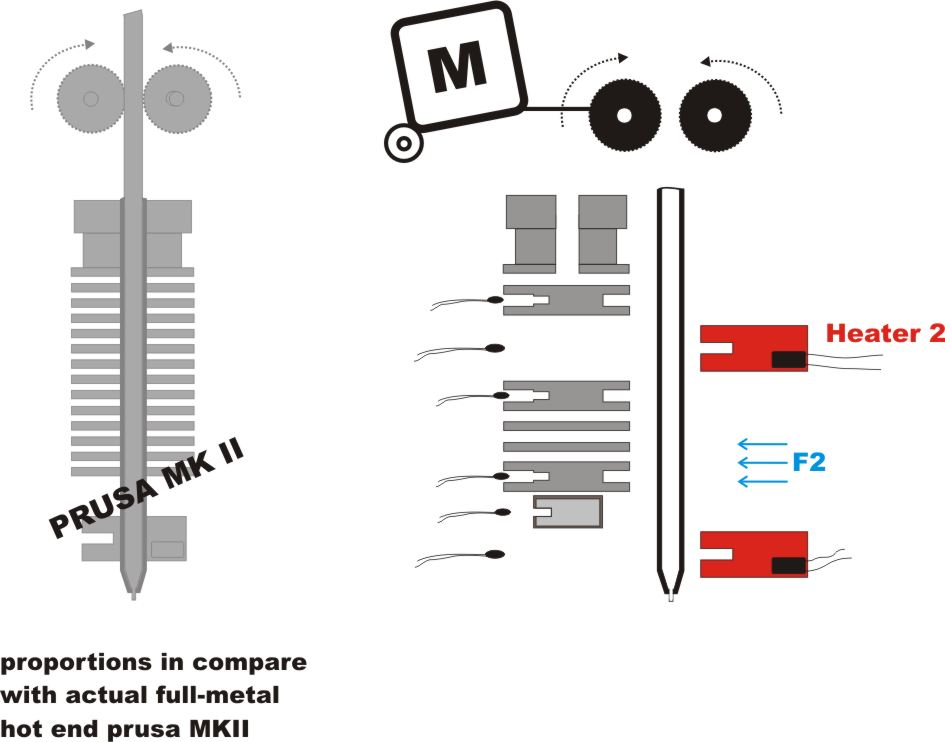

In a nutshell, I would like to raise the current technology of the printheads to the next level. The in secret working developers of the RepRap scene have collected a lot of ideas for this, but the manufacturers build hotends as a hundred years ago and by this may suffer shipwreck as recently MakerBot.

I am seeking for this idea partners who bring enthusiasm to really simplify the 3D printing. This idea requires a pretty penny, which either have only large printer manufacturers or 3D software companies that currently encourage intensive 3D printing. Big names are here: Adobe, Autodesk, also Google and many more.

These companies which do not make money on printers could finance the development of a smart-hotend and then put opensource thus the small garage-printer manufacturers can incorporate the technology into their printers.

If 3D printing is easier it later pays also for the generous software maker.

Of course, also a crowdfunding is conceivable.

In the appendix

the readers who wish to delve deeper with the matter will find PDFs (link to dropbox files) with

- previous hotend developments of Kai Parthy, such as the MultiFilamentHotend (now on everyone’s lips) or a hotend that can pull filaments with a soul into himself,

- and full details on the new > filament detecting hotend <

Would you like to contribute a guest post as well? Please contact us!

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.