Sculpteo – leader in additive manufacturing – proves in their new ebook that 3D printing could help reduce greenhouse gas emissions and the environmental impact of industrial production. This document includes practical advice on optimizing production, sharing resources during the printing process, and designing more sustainable parts to make the right decisions. This approach is part of Sculpteo’s project to offer a more responsible alternative to traditional manufacturing.

An alarming situation for the environment

In 2019, the average atmospheric concentration of CO2 reached 410ppm, a level unprecedented in at least 2 million years . Sculpteo has taken action to reduce its environmental impact and of its customers, by encouraging the adoption of more responsible practices. In the manufacturing industry, the main sustainability problems include energy consumption, waste production, and water use. Producing parts using traditional methods can result in a significant amount of pollution and ecological damage. 3D printing offers several environmental advantages.

Benefit 1 / eco-design:

3D printing opens up previously inconceivable design possibilities. Topological optimization or the integration of lattices in the design of a part can considerably reduce its weight while maintaining its structural integrity . For example, when a part is placed in a vehicle, a 10% reduction in the vehicle’s mass could result in a 6% to 7% reduction in fuel consumption and CO2 emissions .

Benefit 2 / responsible sourcing

3D printing enables functions to be directly integrated into part design, eliminating the need for sourcing additional components and reducing the use and processing of resources.

Benefit 3 / the fight against waste

3D printing tackles obsolescence by enabling on-demand printing of spare parts, avoiding the waste of new resources and the mobilization of traditional production lines. This contributes to the reduction of waste and CO2 emissions. Every year in France, 2 million of large appliances are thrown away for only 5 million repairs . 3D printing is being adopted by professionals like SEB – Rowenta to offer products that are easier to repair. Since 2020, more than 150 3D-printed parts have been available to authorized repairers of SEB Group, with manufacturer certification. Comparatively, producing a 3D-printed replacement part, weighing less than 100g, generates less than 500g of CO2, which is significantly lower than the carbon footprint of a bagless vacuum cleaner, estimated at around 43kg of CO2. This underlines the ecological aspect of repair thanks to 3D printing, which supports traditional techniques.

Benefit 4 / local production

More local and on-demand production reduces emissions linked to transportation and logistics, avoiding for example up to 8,6 tons of CO2 per ton of manufactured parts imported from China by cargo-plane. Also, on-demand production eliminates the need for storage infrastructures, helping to preserve soil and biodiversity.

Benefit 5 / Sharing of impact

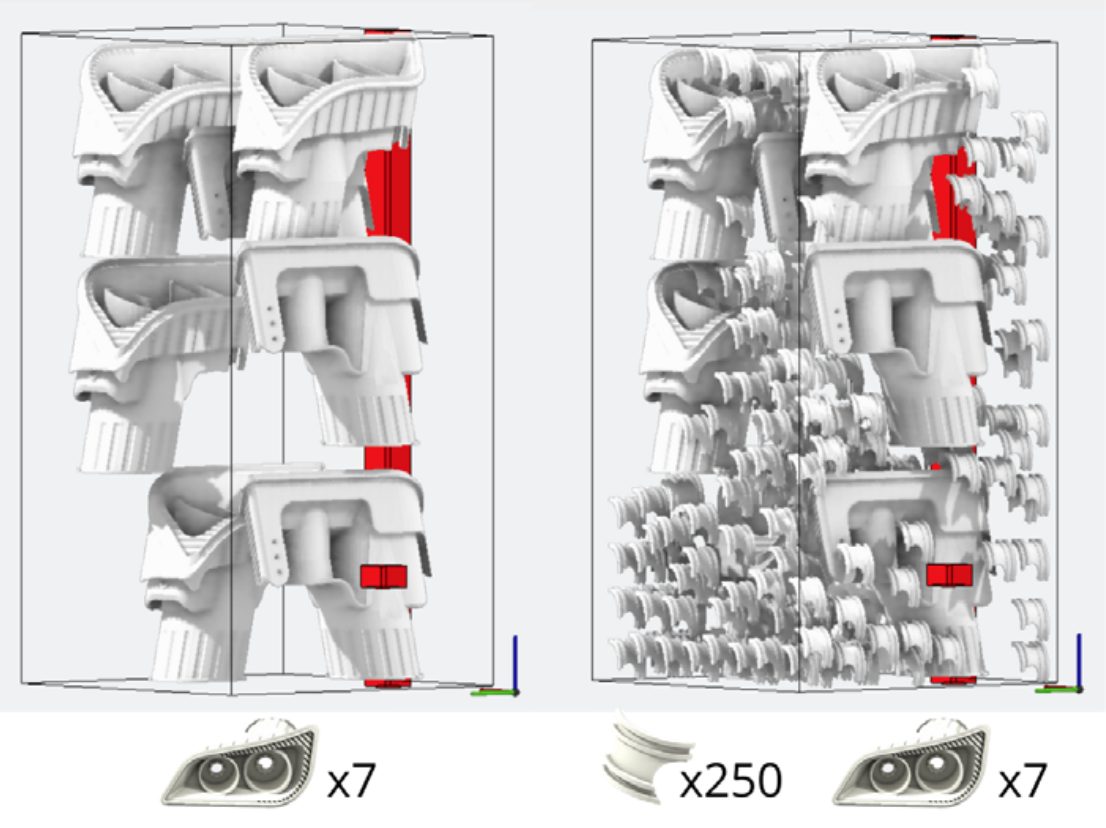

At Sculpteo, the environmental impact of part production is shared among customers. By choosing to print parts at Sculpteo, the customer shares the environmental footprint of the manufacturing of their part with those of other customers’ parts in the same manufacturing job. In the example below, 250 parts have been added. Nesting is optimized and more parts are printed simultaneously, in the same build job, which results in a -22% reduction in the overall environmental impact of parts. In the current context of rising energy prices, Sculpteo has chosen to power 3 of its 4 production sites with renewable energy. This choice influences the environmental impact of the produced parts.

For many companies whose aim is to reduce the impact of climate change, 3D printing is emerging as a relatively attractive alternative.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.