Last year, the five-year research project “Shape-variable wing systems for gliders (MILAN)”, which was funded by the Federal Ministry of Economics and Climate Protection via the German Aerospace Center (DLR) project management organization, was successfully completed. The overriding aim was to improve the aerodynamics of gliding. Additively printed components were manufactured for this purpose at the SKZ Plastics Center.

In collaboration with partners from the Technical University of Munich (TUM), Alexander Schleicher GmbH & Co. Segelflugzeugbau and MP2 Carbon GmbH, the aim was to tap into the significant potential for increasing the performance and efficiency of modern gliders by making their wing structure variable in shape and thus enabling a change between fast and slow states. TUM provided the basis for the project with an aerodynamic design of a glider developed in-house; the wing structure and the actuation system were designed together with Schleicher. The shape-variable wing shell made of a composite material was finally co-developed and built by MP2.

3D-printed components from SKZ

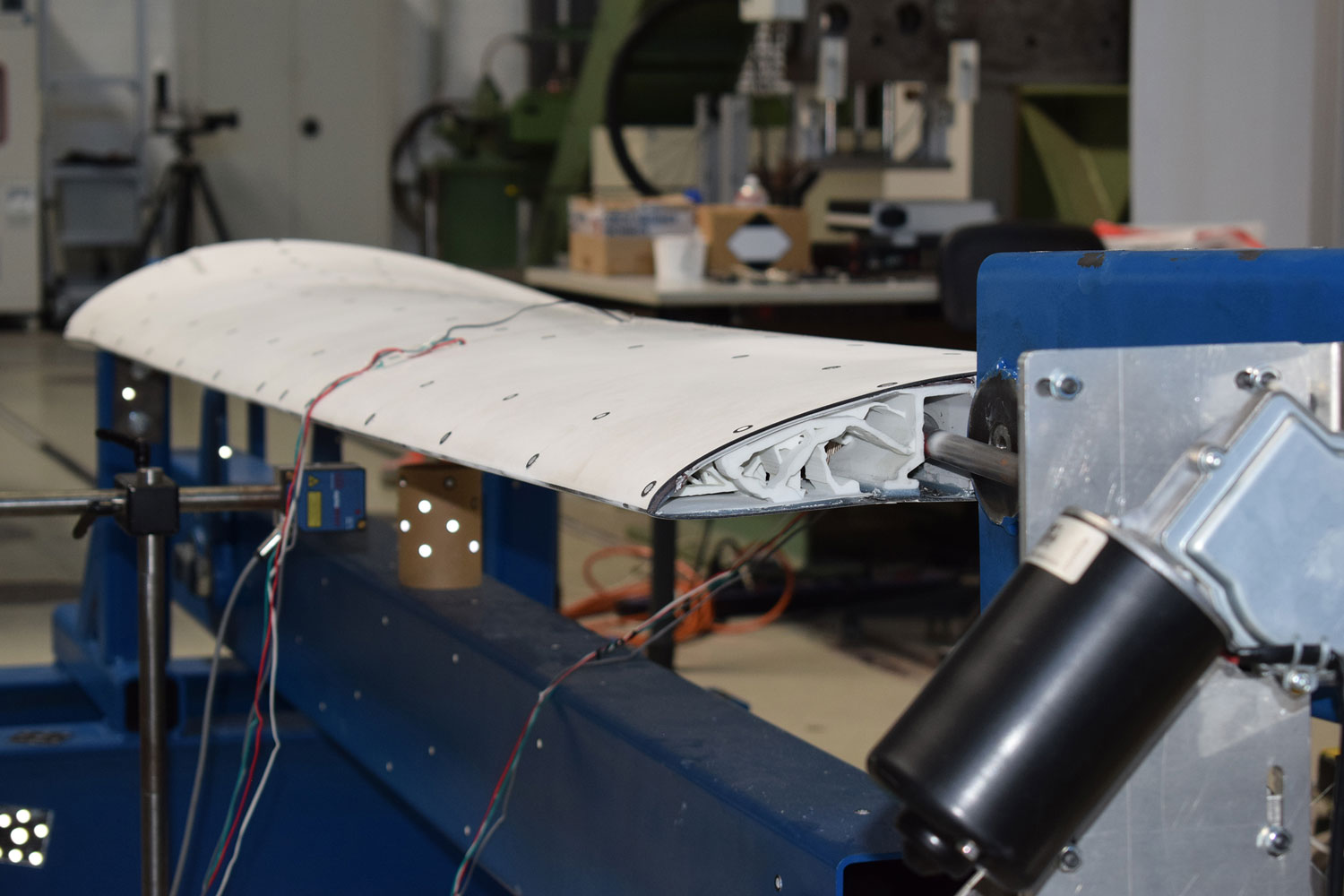

Based on the laminar profile developed at TUM, adaptive adjustment mechanisms, so-called Compliant Mechanisms, were produced at SKZ, which convert an input deformation at an actuation point into a precise change in shape of the entire profile of the leading edge of the wing through the elastic deformation of its truss-like topology. Various additive manufacturing processes (laser sintering, FLM, AKF Freeformer) and materials (including high-performance polymers, FRP) were examined for their suitability. Both intermittent tensile tests to determine a reversibility limit and a specially designed test rig consisting mainly of printed components helped to evaluate the long-term performance of the different hinges. Finally, various mechanisms adapted to the inner wing structure were printed using SLS and installed in a test wing segment. TUM will be responsible for testing this.

“Integrate into other flying objects”

The results generated in the project can also be transferred to other applications in the future. “It is obvious that such additively manufactured components could be integrated into other flying objects, such as light aircraft or drones. But motorsports and sailing, for example, also offer huge potential for using topologically optimized compliant mechanisms from 3D printing,” explains Patrick Limbach, materials developer at SKZ.

The SKZ will continue to expand its expertise in this area and incorporate the results into future research activities with other institutes and companies. Anyone interested in a collaboration is welcome to contact the SKZ.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.