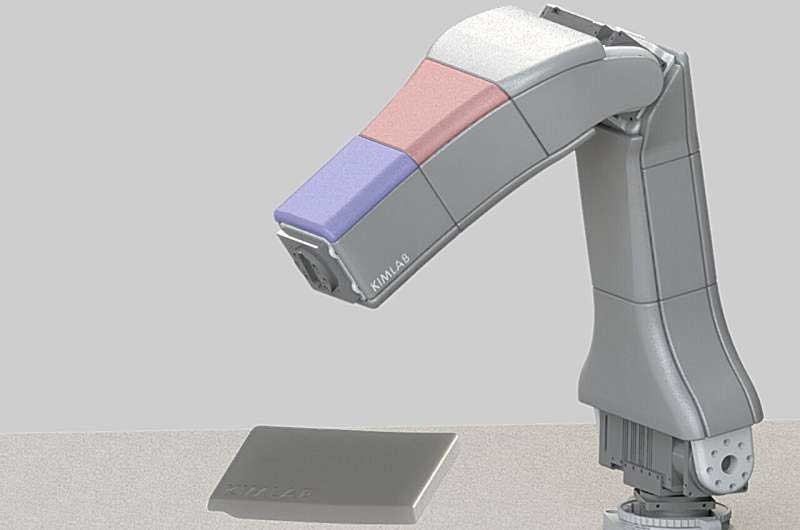

Researchers at the University of Illinois Urbana-Champaign have developed a method for 3D printing soft, tactile sensor pads for robots. The inexpensive, replaceable pads made of thermoplastic polyurethane also serve as safety pads and touch sensors.

The concept utilizes the deformation of the airtight pads: When they touch something, they displace air, which is registered by pressure sensors. This enables robots to recognize physical interactions and react to contact.

“Tactile robot sensors are typically very complex and expensive. We show that there are functional and robust alternatives at low cost,” explains project manager Joohyung Kim. The 3D printing technology can be easily adapted to new robot systems.

In the study, the scientists demonstrated how the sensors contribute to operational safety: if a pad detects contact in dangerous areas such as joints, the robot arm stops automatically. In addition, commands could be issued via touch signals.

As 3D-printed parts are inexpensive, they could be replaced regularly – an advantage for requirements in the healthcare sector, for example. Kim hopes that the simple manufacturing method will increase interest in such soft robotics concepts for more intuitive human-machine interaction.

More on this can be found in the paper “Low-Cost and Easy-to-Build Soft Robotic Skin for Safe and Contact-Rich Human-Robot Collaboration“.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.