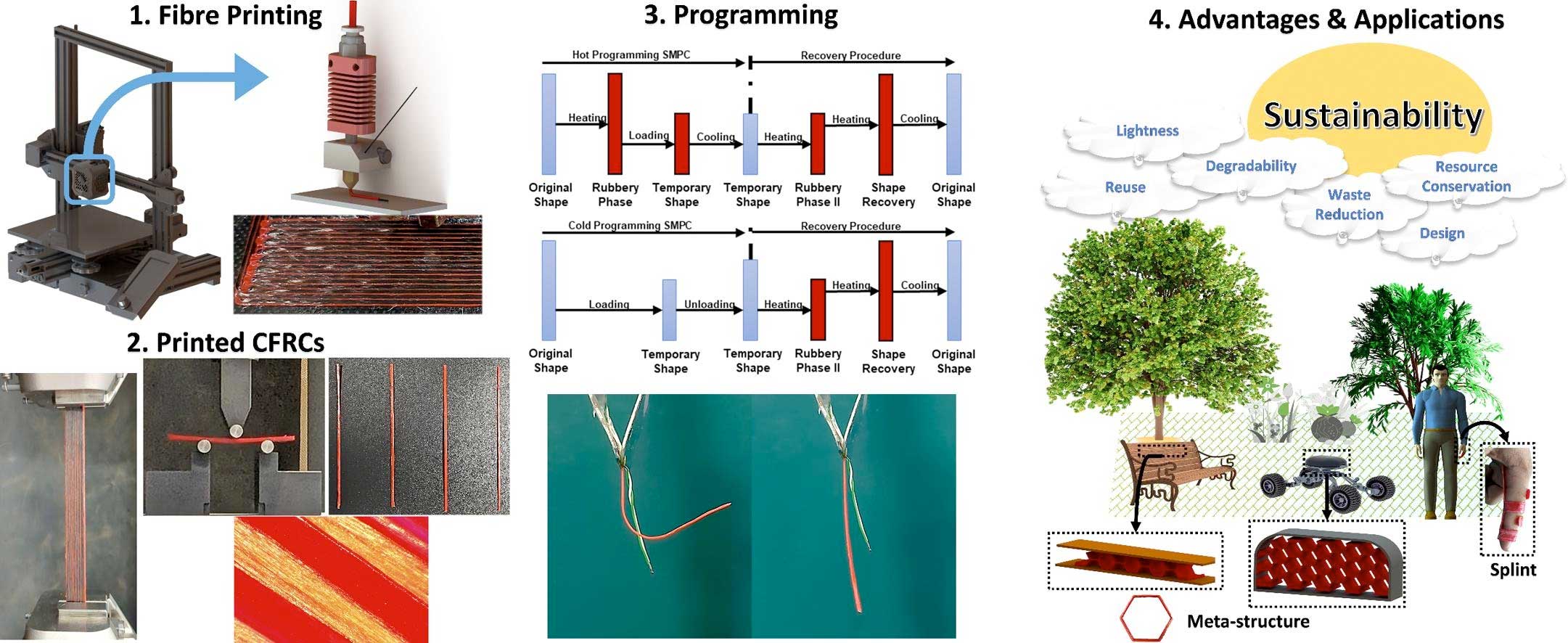

The production of lightweight, robust and environmentally friendly products is increasingly becoming the focus of the 3D printing industry. Scientists have developed a new approach that combines additive manufacturing with sustainable materials and continuous fiber reinforcement. By using 4D printing and shape-memory polymer composites, reusable and durable objects can be produced.

The research group used a modified FFF 3D printer that integrates continuous carbon, aramid and glass fibers into a polylactide matrix. The use of continuous fibers significantly increases the mechanical properties, as the tensile and bending tests showed. Compared to pure PLA, the strength of the composite materials increased by up to 1027.5 % in the tensile test and 497.3 % in the three-point bending test.

In addition to the increased strength, the fiber-reinforced shape memory polymers have a high resilience. When exposed to heat, they largely return to their original shape after deformation. The recovery rate is up to 96% for the glass fiber-PLA composite material. This property allows the printed objects to be reused several times, thus reducing material consumption.

In the study, the scientists demonstrated various applications such as hooks, latches and finger splints made from 4D-printed composite materials. A printed hook weighing just 0.36 g was able to carry loads of up to 500 g. The production of cellular meta-composite structures with high energy absorption was also investigated.

The paper entitled “4D printing and programming of continuous fiber-reinforced shape memory polymer composites” was published in the European Polymer Journal. The online version can be found here. The authors are Mohammadreza Lalegani Dezaki and Mahdi Bodaghi.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.