The Materials Processing Institute is working with Additive Manufacturing Solutions and AMFG to develop an AI tool for materials reuse management as part of a research project funded by Innovate UK.

This tool, known as SMART-APP, aims to increase resource efficiency and waste minimization through advanced predictive models. If successful, this tool, which focuses specifically on laser melting 3D printing technology, will be made available for commercial use.

Nick Parry, Industrial Digitalisation Group Manager at the Teesside-based Materials Processing Institute, commented: “SMART-APP is the next logical step to continue the work the Institute has already undertaken in powder characterisation. This predictive tool will develop and enable world class production of AM components, with smart solutions for resource efficiency and providing longer use of materials feedstock and reducing wastage.”

The SMART-APP project focuses on predicting changes in powder quality after each printing process. It proposes to treat used powder with alternative process parameters to extend its useful life without compromising product quality. The focus is on metal additive manufacturing, which the partners believe is not yet economically viable due to powder waste and long processing times.

Rob Higham, CEO of Additive Manufacturing Solutions, added: “AMS is delighted to have the support of Innovate UK to continue developing our portfolio of world leading powder and AM process optimisation capability. This marks our first step towards a ground-breaking approach for dynamic materials management. The potential of the AM process remains a potential in many people’s eyes. It could be realised with the development of a versatile and smart predictive tool for tracking powder quality after each reuse.”

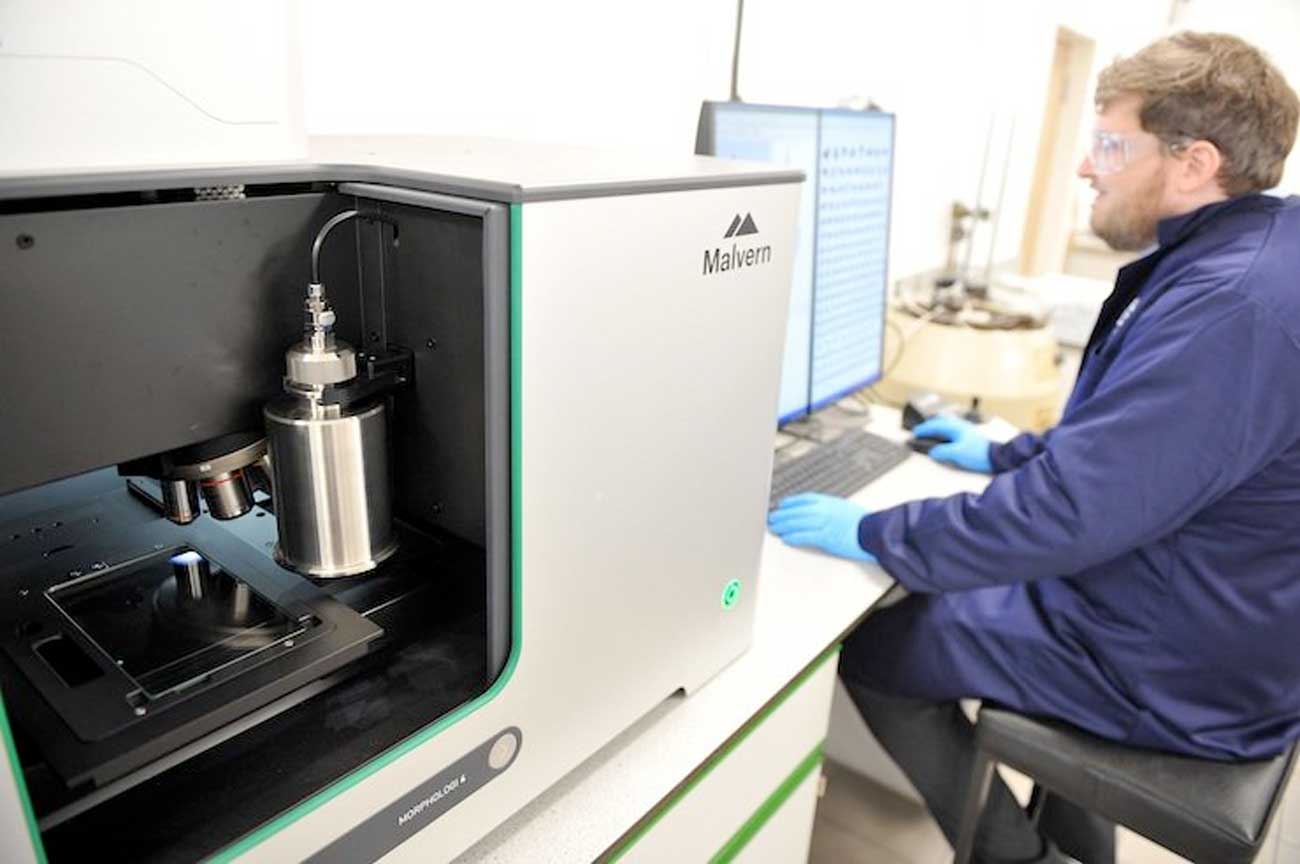

The research project includes state-of-the-art material characterization techniques and mechanical tests. The shelf life and processing limits of environmentally impaired, common raw materials such as stainless steel, titanium and superalloys are also being investigated. The results are incorporated into a comprehensive database that links the properties of the starting powder with the performance of the AM components and thus provides a prognostic tool for the industry.

Alexander Grimmer, Technical Consultant at London-headquartered AMFG, offered: “This initiative aims to transform additive manufacturing towards more resource-efficient methods. SMART-APP aims to instil trust in the additive manufacturing realm by forecasting powder quality and recommending processes to restore desired powder properties for reuse. AMFG eagerly anticipates contributing to a cutting-edge material management system in this project, poised to deliver substantial environmental and economic benefits to the industry. This endeavour is set to expedite the widespread adoption of additive manufacturing.”

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.