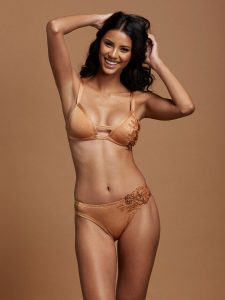

Bambshell® is an exclusive swimwear label created by Melinda Bam, former Miss South Africa from 2011.

– The contestants showed off the Afrocentric Beauty collection which showcases the colorful complexities of African culture in a celebration of color and bold prints. Each print is custom designed for this range and incorporates a mix of ethnic, tribal and modern prints on voluminous capes, juxtaposed against the sleek silhouettes of the swimsuits – says Melinda Bam.

From a costume to ready-to-wear fashion

Fashion needs flexibility

– Most of our clients use hard materials like PA12. It becomes a standard for a broad range of industries. But fashion needs more flexible solutions – says Konrad Głowacki, one of the Sinterit Co-Founders. – It is not so easy to find a dependable, flexible material that would be a perfect match for the fashion industry and available for 3D printers. But as several years ago only a few people believed that SLS technology could become a desktop solution, available for every company, now we would like to go forward with the range of materials. After months of testing, we are happy to provide two reliable products: Flexa Black and Flexa Gray – adds Głowacki.

New era to come

Twenty years ago nobody thought that people would buy music files and download them to their computers, rather than visit the music shop to get the new CD. In the nearest future, the same could happen to the fashion industry. If not for the entire collections, then for at least some accessories.

This project was possible thanks to Build Volume, a company which is all about bringing 3D printing into the life of regular people and undoubtedly one of the most important 3D printing spots in South Africa.

Due to the fast development of 3D printers, 3D scanners, and modeling software, 3D printing is becoming more and more exciting and affordable for personal users. With 3D printing, “everything” is possible – says Don Vermeulen, the CEO of Build Volume and a person who personally printed the flowers for the Bambshell collection on Sinterit Lisa 3D printer.

His company offers a steadily growing selection of everything you need for your own 3D printing projects.

Now, thanks to the office-size Sinterit Lisa, it is possible to use this most sophisticated 3D laser sintering technology in the accessible and affordable way. With the SLS technology, it is possible to print almost every shape in one piece, both from hard and also soft material. The company has experience in other fashion applications and just launched Sinterit Lisa Pro, even more advanced 3d printer – if you want to try your creative designs, reserve the product on the website.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.