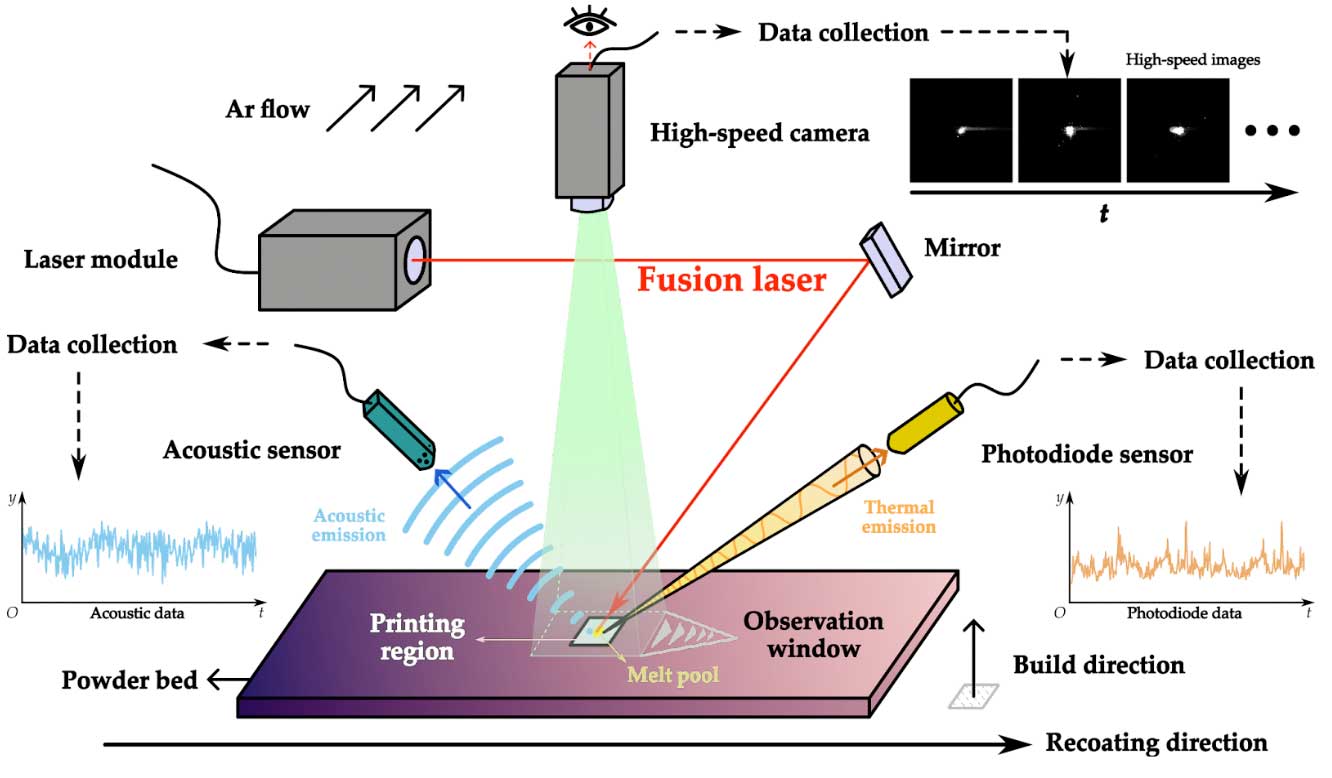

Researchers at Carnegie Mellon University have developed a novel AI method that simplifies the monitoring of the 3D printing process for metal components. Instead of expensive high-speed cameras, the approach uses low-cost sensors for sound and heat emissions to reconstruct critical parameters in real time.

“Our system uses deep learning to record the physical processes of the process parameters,” explains Haolin Liu, a doctoral student in the working group. One advantage is the early detection of defects caused by insufficient melting of the powder. These critical defects significantly weaken the mechanical properties of the component. The AI-supported monitoring of the selective laser melting of titanium alloys showed promising results in the detection of such defects.

“Our method enables cost-effective process monitoring for any 3D metal printer through the use of simple sensors,” emphasizes Professor Jack Beuth. The reconstruction of melt pool videos from acoustic and thermal data is unique in additive manufacturing.

The research team wants to further deepen the new insights into the relationships between the various signals. “Although the interactions between sound, heat and the melt pool are known, we do not yet fully understand their exact relationships,” says Professor Levent Burak Kara. The deep learning model already links these phenomena in a data-based but physically meaningful way.

According to Professor Anthony Rollett, acoustic behaviors provide crucial insights into laser-material interactions that are far more revealing than previously thought. “In the long term, we want to better understand the relationships between sound, heat and process fluctuations,” says Haolin Liu. “Our goal is to develop advanced surrogate models and digital twins for additive manufacturing.”

Further details on the work can be found in the paper “Inference of highly time-resolved melt pool visual characteristics and spatially-dependent lack-of-fusion defects in laser powder bed fusion using acoustic and thermal emission data“.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.