3D printer manufacturer Desktop Metal announced the sale of a Production System P-50 and a complete fleet of Metal Binder Jet systems to FreeFORM Technologies. This strategic move strengthens Desktop Metal’s presence in the expanding metal 3D printing market.

FreeFORM Technologies, based in St. Marys, now has a total of 25 metallic printers through this sale. Prior to this transaction, the company already owned nine Binder Jet systems from Desktop Metal. With this impressive fleet, FreeFORM now serves hundreds of customers worldwide. In total, the company has produced more than 350,000 parts using binder jetting technology for customers in the industrial, defense, medical, robotics, and consumer markets.

A special highlight is the collaboration between FreeFORM Technologies and Ryerson Holding Corporation. Their capabilities will be showcased in partnership at Fabtech, North America’s largest metal forming and processing event, in Chicago, September 11-14.

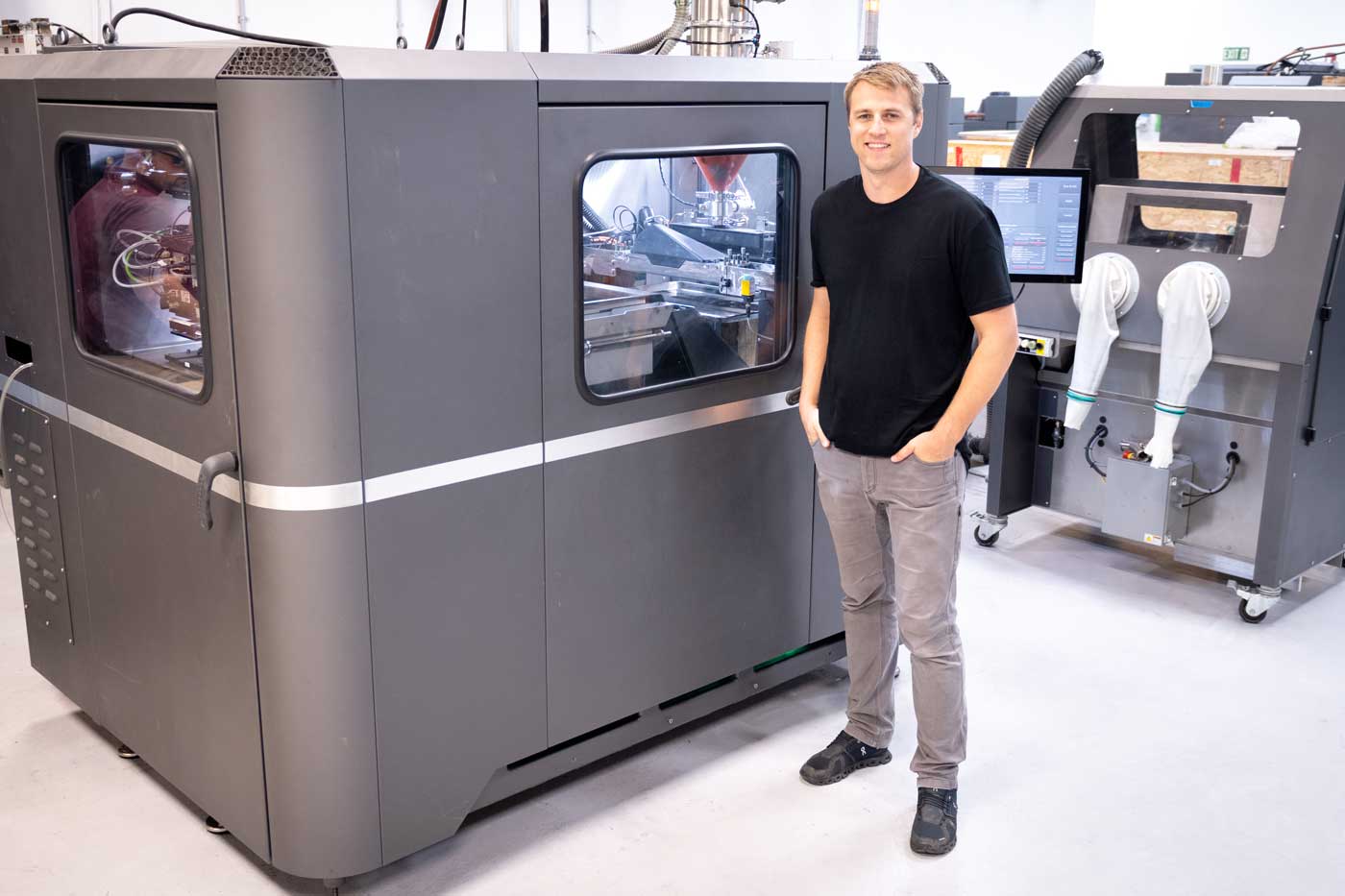

“FreeFORM’s investment in metal binder jetting demonstrates our continued commitment to employing world-class additive manufacturing processes to meet the needs of our customers,” said Nate Higgins, President of FreeFORM. “This addition of DM printers strengthens our capabilities in this area, allowing us to provide greater cost efficiency and speed to market.”

“Desktop Metal is delighted to see a startup with deep experience in powder metal and sinter-based technologies pushing the limits of what metal binder jet 3D printing technology can do,” said Ric Fulop, Founder and CEO of Desktop Metal. “FreeFORM is leading the way among our Super Fleet owners, which we define as customers using three or more of our Additive Manufacturing 2.0 systems. Desktop Metal now has hundreds of Super Fleet customers worldwide delivering final production of metal, polymer, and ceramic parts with our binder jet additive manufacturing systems. We remain confident that the cost, quality and material flexibility offered by binder jetting will continue its momentum in serial AM production.”

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.