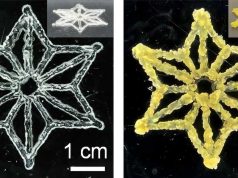

Researchers at Stanford University have developed a new method for energy-efficient 3D printing with resin. Using a physical effect called “photon upconversion,” they can produce high-precision prints with weak lasers.

High conversion converts low-energy photons into higher-energy ones. The team led by Tracy Schloemer and Daniel Congreve uses this effect to locally generate blue light from a red laser beam. This blue light then selectively hardens resin dots, enabling layer-by-layer printing.

Unlike conventional resin printers that use UV or blue light, a laser pointer-like weak red laser is all that is needed here. According to the researchers, this enables fast and precise 3D printing at the nanoscale without damaging the resin with intense laser radiation.

In addition to its application in additive manufacturing, optical upconversion is also expected to increase the efficiency of solar cells. Overall, the method could thus open up new possibilities for advanced 3D printing processes and in the field of renewable energy. The results were obtained at Stanford University’s Congreve Laboratory.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.