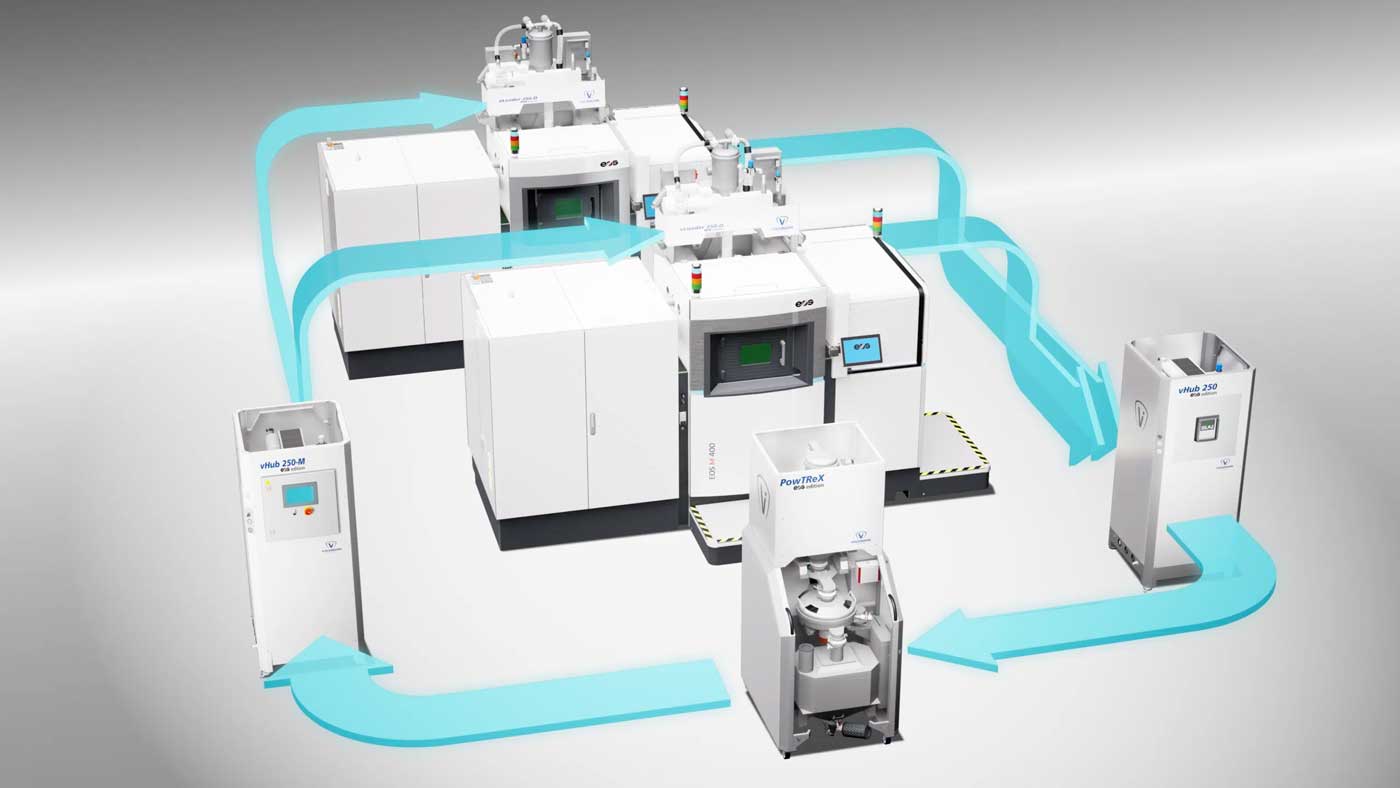

VOLKMANN and EOS announced a scalable, closed-loop metal powder handling solution for users of the EOS M 290, EOS M 400 and EOS M 300 series additive manufacturing systems.

This system enables a holistic approach to powder handling – from powder preparation to a closed, fully automated powder cycle.

The partnership between VOLKMANN, a leading supplier of innovative powder handling systems, and EOS, a pioneer in additive manufacturing technology, has resulted in a system that is characterized by safety, increased productivity and flexibility. The closed powder system protects both the operator from exposure to dust and the material from environmental influences and contamination. At the same time, it enables rapid depowdering and automatic refilling of the powder parallel to the printing process, which significantly increases the process reliability and productivity of the machines.

Thanks to the fully automated powder handling, up to six 3D printers can be integrated into one production cell, with step-by-step scaling possible. This means that existing printers can be easily integrated into the system. A key advantage is the reduction in manual work processes, which enables 24/7 operational readiness. The modular design of the system allows individual process steps to be carried out by connecting several devices and can be expanded into a fully automated system if production is extended at a later date.

Overall, this solution offers a central, high-performance powder handling system that can supply up to six EOS M 400 or EOS M 300 series AM systems in one production cell. In addition, the system ensures high powder quality through optional drying and closed process steps. With this innovation, end users have a single point of contact for 3D printing and powder handling, from project planning and commissioning to the entire life cycle of the system and service.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.