EOS, the technology and market leader for design-driven and industrial Additive Manufacturing solutions, expands its metal materials portfolio with EOS Titanium Ti64ELI and EOS StainlessSteel 316L. Christiane Krempl, Product Marketing Manager Metals at EOS adds: “A broader variety of titanium and stainless steel materials mirrors the ever changing requirements among our customers and opens up new fields of application.”

EOS Titanium Ti64ELI: light metal alloy – corrosion resistant and excellent mechanical properties

Parts built in EOS Titanium Ti64 have a chemical composition and mechanical properties corresponding to ASTM F136. Providing a high detail resolution it can be processed on an EOSINT M 280 (400 Watt) metal laser-sintering system. This light metal alloy shows an excellent corrosion resistance. Due to its biocompatibility and high grade of purity it is particularly suited for the additive manufacturing of medical implants.

EOS StainlessSteel 316L: corrosion resistant stainless steel with high ductility

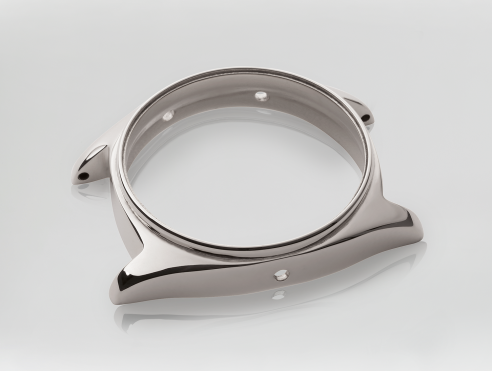

This stainless steel alloy has been optimized specifically for the processing on the EOSINT M 280 metal laser-sintering system. It shows a good corrosion resistance and a high ductility. Parts built from EOS StainlessSteel 316L have a chemical composition corresponding to ASTM F138 (“Standard Specification for Wrought 18Cr-14Ni-2.5Mo Stainless Steel Bar and Wire for Surgical Implants UNS S31673)”. In the medical industry, this alloy is particularly suited for surgical instruments, for endoscopic surgery, orthopedics and implants.

The material is also a good choice for use in the watch and jewelry industry, where the designer benefits from extensive freedom of design. Shaping and structural restrictions as such are a thing of the past. Parts such as watch cases thanks to defined hollow spaces can be manufactured more cost-efficiently and easily, at the same time saving resources. The material is also well suited for additive manufacturing applications such as spectacle frames or functional elements in yachts. In the aerospace industry EOS StainlessSteel is a good choice for the manufacture of clamping elements or heat exchangers. Parts manufactured from that material can mechanically post-processed or polished.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.