The European HyP3D project is positioning itself as a pioneering initiative in hydrogen production. It aims to use advanced 3D printing technologies to fundamentally improve the efficiency and sustainability of solid oxide electrolysis cell (SOEC) technology.

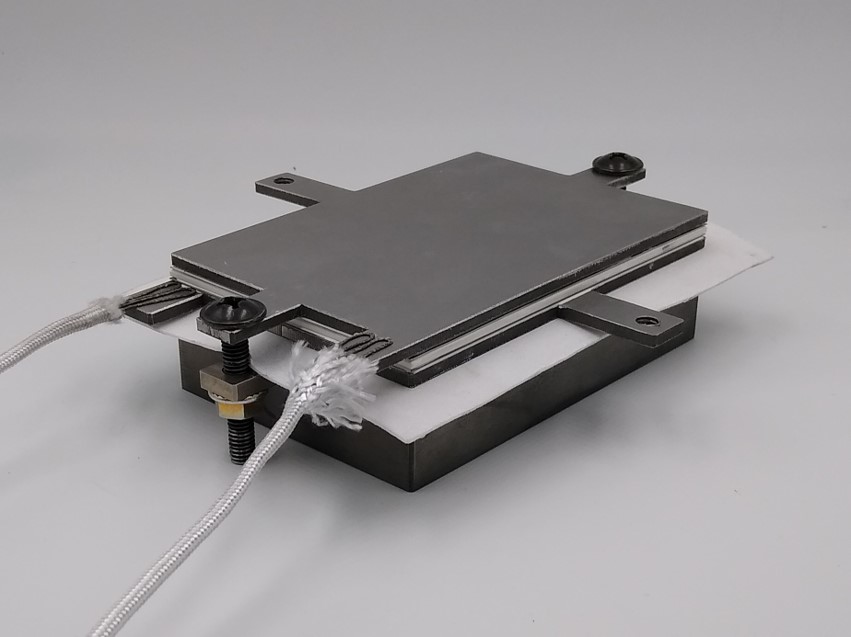

At the heart of the project is the ambitious goal of developing an ultra-compact, self-sufficient, high-pressure SOEC stack that converts electricity into compressed hydrogen. In contrast to conventional methods, HyP3D relies on the power of 3D-printed SOEC cells, which offer a substantial active area of 70 cm², integrated functions and the ability to produce hydrogen at high current densities above 0.90A/cm² (~1.3V) under conditions of 850ºC and more than 5 bar pressure.

A major breakthrough of the HyP3D project is the paradigm shift from traditional ceramic processing to SOEC. The result is the creation of extremely high power density SOEC stacks that achieve 2.14 kW of power in a compact 630 cm³ volume. This means a tripling of the specific power per unit volume (3.4 kW/L) and a quadrupling of the specific power per unit mass (1.10 kW/kg), exceeding existing benchmarks.

H2B2, a key partner in the HyP3D project, specializes in all aspects of hydrogen production systems. With its expertise in energy efficiency and cost reduction, H2B2 plays a crucial role in the success of the project. Their responsibility for the production pilot line underlines their contribution to the efficient production of the HyP3D cells.

3DCeram, another collaborator, focuses on the optimization of printable feedstock, 3D printing parameters and thermal treatments. By developing specialized slurries for SLA 3D printing with commercial YSZ powders, the teams are researching rheological behavior and printing tests. Innovation extends to the design of optimal processes, culminating in the production of complex shaped parts that match the final cell dimensions.

The HyP3D project goes beyond the production of dense, mechanically robust components. 3DCeram and IREC are working on optimal printing strategies to ensure reliability and maximize production yields. The project is in line with the overall goals of advancing the hydrogen economy, significantly reducing time to market, reducing raw material consumption by 76% and reducing initial investment by 42% compared to conventional manufacturing processes.

With this groundbreaking initiative from the HyP3D project, the energy sector is experiencing a convergence of 3D printing expertise and hydrogen innovation that is leading the world towards a more sustainable energy future.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.