With up to three different wavelengths in one device and a peak power of 13W, Helios Duo and Helios Trio pave the way for new application areas for 3D printing, lithography and bioengineering.

“We were repeatedly confronted with the wish to enable high- precision exposure with multiple wavelengths”, says In-Vision’s CEO, Florian Zangerl.

So it made perfect sense to develop a technology that fulfills this need and to integrate it into the top model of the Austrian supplier of high-end projectors. With Helios Duo and Helios Trio, it is possible to work with up to three multiple wavelengths from 365 to 405 nanometers.

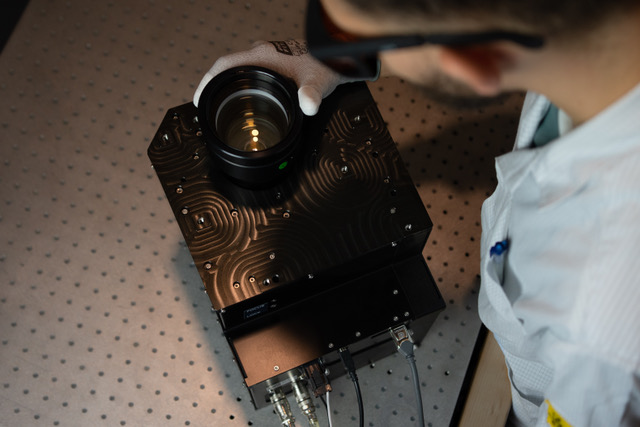

In future, there will also be illumination modules with 460 nanometers available. The customer is free to choose between the configurations, with a choice of lenses for pixel sizes from 2 to 162um. The system is water-cooled with a fully encapsulated light path. Robust in design, it can cope with rough production environments where dust and vapours are very hard on optical systems.

Unlimited possibilities

There are virtually no limits to the applications for multiple wavelength exposure: whether for combination with different UV ranges simultaneously, sequential exposure for curing support structures in 3D-Printing or simply for more efficient material development.

“With the new Helios systems, we are placing a powerful tool in the hands of manufacturers and developers,” says CTO Christof Hieger.

At the top of its game, Helios comes with a native resolution of 2560×1600 pixels that has already proven in numerous industrial applications on simply how reliable a projector can be, even with the peak power being the highest in the market. All optical elements and their coatings have been optimized to offer the best uniformity and contrast ratios. Additionally, and most importantly for industrial users – the entire projector is based on a modular design: entirely built from sub-assemblies, it offers maximum accessibility, enabling the customer to exchange the LED module in the field.

Find out more about In-Vision at in-vision.at.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.