Anne Bentley, professor of chemistry at Lewis & Clark College, has developed an innovative way to teach nanoscience using 3D-printed models that make the invisible visible.

These particles, as small as a nanometer, are of great interest to materials scientists because of their unique physical and chemical properties. They are invisible to the naked eye and require specialized electron microscopes to view.

Bentley, a member of the chemistry department at Lewis & Clark College in Portland, Oregon, explains, “I think a lot of chemistry is outside the realm of what people can hold in their hands. You can obtain evidence about what’s going on, but you’re still investigating something that’s at too small a scale for your eyes to see. Anything you can do to scale it up is helpful.”

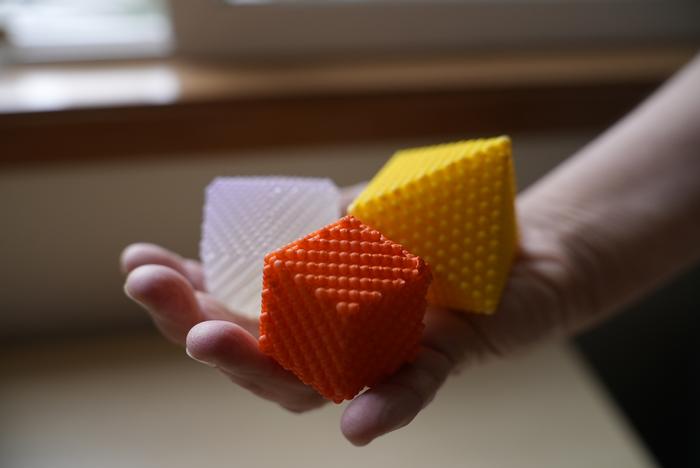

Bentley therefore created 3D models of the simplest geometric shapes that nanoparticles take on. She published the instructions for creating these models, either with paper or 3D printing material, in an article she co-authored in the Journal of Chemical Education: “A Primer on Lattice Planes, Crystal Facets, and Nanoparticle Shape Control.”

In this article, Bentley focuses on low-index shapes, which she describes as the three simplest ways to cut a structure.

“The shapes are derived from this packing of the atoms,” she says. “The motivation to make different shapes really comes down to the arrangement of the atoms when the material is sliced in different ways on different crystal planes. There are lots more complex ways to slice it, but these are the three fundamental ways to do it, by making them either six, eight, or twelve sides―cubes, octahedra, or rhombic dodecahedra. It was a natural choice to focus on those three for the article.”

“Nanoscience is a topic that both falls between chemistry and physics in the curriculum, but also between undergraduate- and graduate-level research,” says Bentley. “It’s important that beginning materials chemists have a fundamental understanding of crystal planes, facets, and directions of growth. They also need to understand the three-digit notation system used to index these attributes, known as the Miller indices. Otherwise, this system can look like a mysterious jumble of numbers.”

In particular, the three-digit notation system for indexing these attributes, known as Miller indices, can seem like a mysterious jumble of numbers without the proper foundation.

In Bentley’s lab, she and her students are working on manipulating gold atoms in liquid containers to control the shape of the nanoparticles. Gold nanoparticles are known for their catalytic properties, i.e. their ability to accelerate chemical reactions. One shape in particular, the dodecagonal rhombic dodecahedron, has been shown to be more effective at converting carbon dioxide into fuels.

“It’s like recycling,” says Bentley. “Not only does this nanoparticle shape enable researchers to remove carbon dioxide from the atmosphere, but it allows them to turn it back into some kind of fuel that can be used. So if we can grow particles that have this facet on them only, that’s a real advantage.”

In summary, Bentley’s approach offers an innovative way to make nanoscience tangible and understandable through 3D printing technology. Her work illustrates the link between theoretical research and practical application, a crucial step in the education of future materials scientists.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.