Unique items in industrial production quality – the best way to achieve this is with 3D printing. In order to straighten the strand structure created during this process, objects are post-processed, for example milled. At KraussMaffei, the sites in Parsdorf (additive manufacturing) and Harderberg/Gorgsmarienhütte (toolmaking) work together for this purpose. The customer receives his complete component from a single source.

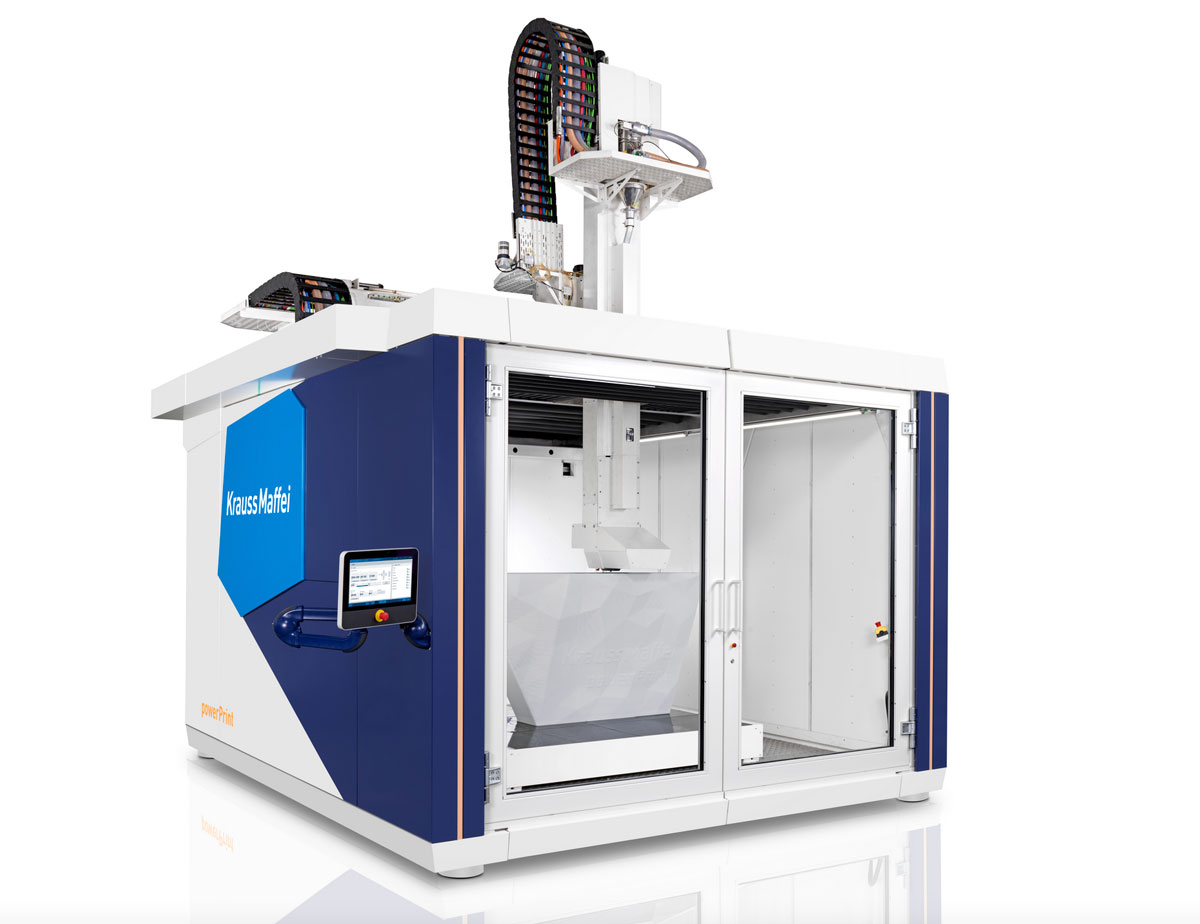

The powerPrint large-format printer can be used to produce components measuring up to 2 x 2.5 x 2 meters. This can be done either by purchasing such a printer yourself or by using print on demand. With this service, KraussMaffei takes care of the entire project, from data optimization to the perfect surface.

When customers first asked Ender Murat Ferat (Project Engineer Additive Manufacturing) in Parsdorf about this service, he didn’t immediately think of his toolmaking colleagues in Harderberg. No wonder, because they mainly work for the company’s reaction technology division and produce molds for PUR processing, among other things. “We initially tried working with external milling companies, but working in-house is of course much more efficient and you also retain the expertise,” explains Ender Murat Ferat.

Once contact had been established between the sites, joint development began. In Harderberg, they had already been milling plastic as well as metal, but mostly material made from Ureol, a polyurethane or epoxy resin saturated with fillers in sheet and block form. Production Manager Stefan Springrose explains: “Our products include prototypes and leatherette models for the automotive industry.” Recycled PETG with 30 percent glass fiber reinforcement will now be used for 3D printing.

Milling of plastics

Milling plastics requires different machines to those used for metal because the machining process is simpler and involves more material removal. For this reason, less powerful but highly dynamic machines are used in order to achieve the highest possible cutting speeds and fast production times. The tools used must be extremely sharp and require optimum chip removal. During tests with the glass fiber-reinforced PET, Thorsten Richter, team leader of the milling shop in Harderberg, even discovered “that diamond-coated milling cutters are necessary in order to withstand the abrasive material. This significantly reduces wear.”

The edge structure familiar from additive manufacturing can thus be completely smoothed. To let customers feel how fine the surfaces can become, Ender Murat Ferat always has corresponding sample plates with him. So far, they have reached a roughness depth of RZ 12, but Thorsten Richter emphasizes that it can be even smoother: “It just takes longer.”

One project that the colleagues in Bavaria and Lower Saxony have already implemented together is a sand casting mold for pressure pads. For this process, a negative mold is first made to produce the actual sand mold, which in turn holds the liquid metal (iron, aluminum, etc.). The sand mold is destroyed during demolding, and the milled 3D body can be used again and again. Until now, ureol was usually used for this. Despite the higher costs per kilo of raw material, additive manufacturing offers two decisive advantages. Firstly, the models are significantly more resistant to breakage, and secondly, you are independent of the standard dimensions of the ureol blocks and plates. These usually do not correspond to the dimensions required for the project, so they have to be glued together by hand to the required size. The associated labor input can be saved if the 3D printer produces a blank that only needs to be built up where the end product requires material. This ultimately makes the 3D mold cheaper than its Ureol counterpart, despite the higher base price for the PETG.

The cooperation between additive manufacturing and toolmaking benefits both sides because each area can now offer additional services. Print on demand customers receive their workpieces from a single source with a perfect finish. Existing customers of Ureol models can use the more break-resistant PET GF30.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.