LAMQC LLC is proud to announce the launch of their real time inspection and acceptance software, designed for powder-bed additive manufacturing machines.

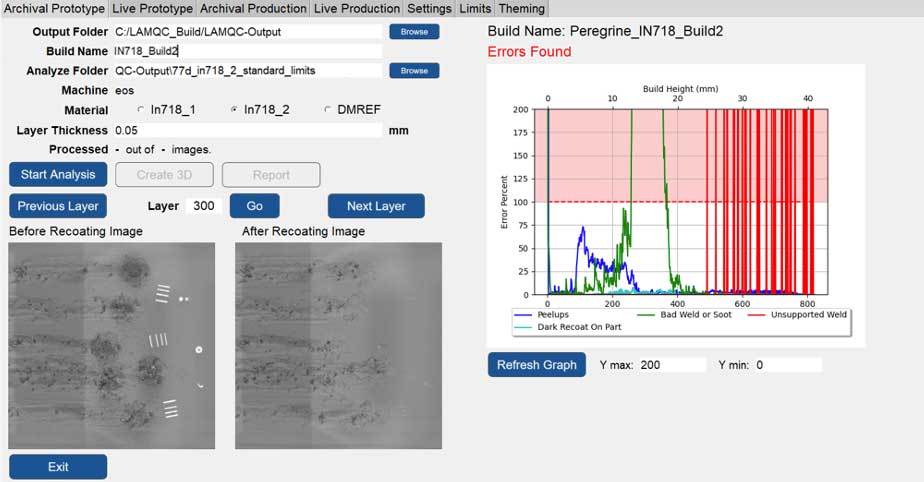

LAMQC software uses existing layer camera images (as well as other sensing modalities) to transform gigabytes of layer camera data into timely and actionable run charts, control charts, email notifications, solid models and build reports.

Other similar software results in false positives so frequently that many have turned off user alerts. LAMQC eliminates false positives by allowing users to customize anomaly limits for each anomaly type and notifies operators only if the limits are exceeded.

False positives are further reduced for AM serial production by comparing the current build to qualified build(s). Operators are notified of build-to-build differences with control charts and solid models to provide needed context.

LAMQC allows users to find and fix anomalies, stop parts or stop entire builds to prevent wasted machine time and powder, prove build-to-build repeatability for production parts with control charts, and communicate anomaly locations and sizes with solid models overlayed on build files.

LAMQC runs on local computers, not on the cloud, eliminating potential ITAR, Export Control and DFAR compliance complications.

The software is offered for use in single-builds, yearly licenses for single machines and site licenses depending on customer’s needs. More information about this technology can be found directly at LAMQC.com.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.