3D printing software specialist Materialise has teamed up with Korea-based 3D printer manufacturers Lincsolution, Gooo3D, Former’s Farm and CA Tech Work to provide customised software solutions for their desktop 3D printers.

Materialise partners with manufacturers of 3D printers all over the world to improve the communication between 3D software and a wide range of 3D printers.

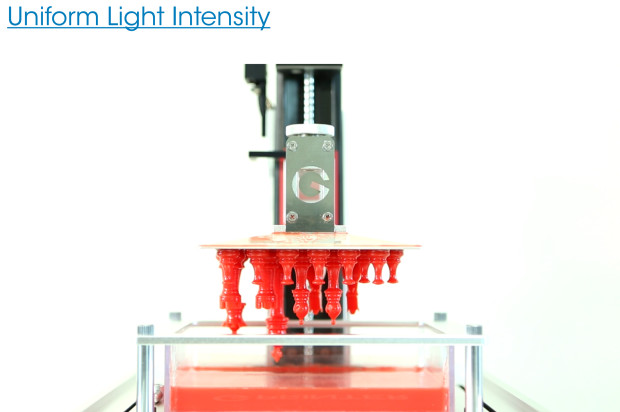

Seoul-based Gooo3D has recently launched an Indiegogo campaign for their UV DLP 3D printer. Materialise and Gooo3D will work together to equip the G printers with powerful 3D printing software, called G Printer Studio.

Former’s Farm specialised in developing and distribution filament, building desktop FDM printer for educational, prototyping and design purposes and providing print services for prototyping companies. The customised Builder software developed in cooperation with Materialise allows for simplifying the 3D printing process. The intuitive user interface will guide new and experienced users from uploading the file to watching their model print before their eyes. Users will be able to easily analyze their file, generate support structures and slice it. If their models contains errors, they will be able to repair them via 3DPrintCloud, a toolkit for 3D Printing in the cloud that helps users prepare their models for 3D Printing through an easy, fast, automated and secure process.

Through their partnership with Materialise, Lincsolution will offer the Link Builder for their desktop FDM printer. The software is based on Materialise’s data preparation software Magics, combined with a Build Processor framework. This framework will ensure that users can slice and hatch files in a fast and reliable way.

CA Tech Work will include the Build Processor for their bottom-up system Mobius, using an LCD panel as a light source to harden layers of resin. In addition, users of the Mobius printers will have access to functionalities of Magics. This enables them to analyze errors in STL files, repair them, edit the files, and more. The repaired design with the optimal support structures can then be sliced and printed on a Mobius DLP printer.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.