Scientists from the Micro, Nano and Molecular Systems Lab at the Max Planck Institute for Medical Research and the Institute for Molecular Systems Engineering and Advanced Materials at Heidelberg University have created a new technology to assemble matter in 3D.

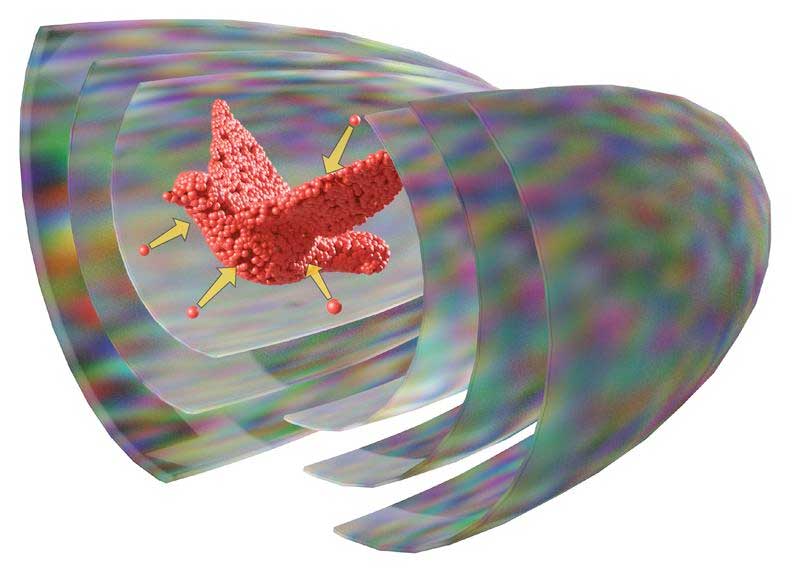

Their concept uses multiple acoustic holograms to generate pressure fields with which solid particles, gel beads and even biological cells can be printed. These results pave the way for novel 3D cell culture techniques with applications in biomedical engineering. The results of the study were published in the journal Science Advances on February 08.

Additive manufacturing or 3D printing enables the fabrication of complex parts from functional or biological materials. Conventional 3D printing can be a slow process, where objects are constructed one line or one layer at a time. Researchers in Heidelberg and Tübingen now demonstrate how to form a 3D object from smaller building blocks in just a single step.

“We were able to assemble microparticles into a three-dimensional object within a single shot using shaped ultrasound”, says Kai Melde, postdoc in the group and first author of the study. “This can be very useful for bioprinting. The cells used there are particularly sensitive to the environment during the process”, adds Peer Fischer, Professor at Heidelberg University.

Sound waves exert forces on matter – a fact that is known to any concert goer who experiences the pressure waves from a loudspeaker. Using high-frequency ultrasound, which is inaudible to the human ear, the wavelengths can be pushed below a millimeter into the microscopic realm, which is used by the researcher to manipulate very small building blocks, like biological cells.

In their previous studies Peer Fischer and colleagues showed how to form ultrasound using acoustic holograms – 3D-printed plates, which are made to encode a specific sound field. Those sound fields, they demonstrated, can be used to assemble materials into two-dimensional patterns. Based on this the scientists devised a fabrication concept.

With their new study the team was able to take their concept a step further. They capture particles and cells freely floating in water and assemble them into three-dimensional shapes. On top of that, the new method works with a variety of materials including glass or hydrogel beads and biological cells.

First author Kai Melde says that “the crucial idea was to use multiple acoustic holograms together and form a combined field that can catch the particles”.

Heiner Kremer, who wrote the algorithm to optimize the hologram fields, adds: “The digitization of an entire 3D object into ultrasound hologram fields is computationally very demanding and required us to come up with a new computation routine”.

The scientists believe that their technology is a promising platform for the formation of cell cultures and tissues in 3D. The advantage of ultrasound is that it is gentle for using biological cells and that it can travel deep into tissue. This way it can be used to remotely manipulate and push cells without harm.

Find out more about the Max-Planck-Institut at mpg.de.

For more information about Heidelberg University, please visit uni-heidelberg.de.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.