In the past, surgery often used titanium mesh to fill in autologous or allogeneic bone as an interbody support material. However, once the titanium mesh is displaced compressing the spinal cord, the patient is at risk of paralysis. 3D-printing now offers alternatives to tackle this problem.

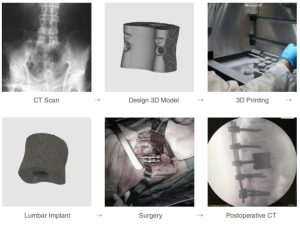

The solution is to establish a precise 3D model based on the CT scanned data, design the surface of 3D polygonal structures and mechanically optimized lattice structure inside. The spongy microporous structure combined with the topological frame structure facilitates the growth of bone cells, and finally achieves bone fusion, which has stronger bearing capacity than the conventional titanium mesh.

This can be achieved, using the Eplus3D metal 3D-printer EP-M260, an industrial metal 3D printer that uses advanced metal powder bed fusion (MPBF) technology. It is capable of easily and quickly converting CAD data into high-performance, complex structure metal parts. The 3D printer is an ideal choice for medium sized parts and small batch production.

Advantages

In a medical case, the 3D printed artificial vertebral body was completely reconstructed and fixed according to the anatomy of the patient. After installing the precise and personalized artificial spine, the patient who was a truck driver recovered well and was able to drive a few months later.

Material: Titanium Alloy

Technology: MPBF

Print Time: about 12h

Process: 3D Printing + heat treatment + cutting + sand blasting

For more information about EPlus3D, please visit www.eplus3d.com.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.