Researchers at the University of Nottingham have developed a new coating for plastic particles used in 3D printing. It significantly increases their functionality and opens up new possibilities for commercial use.

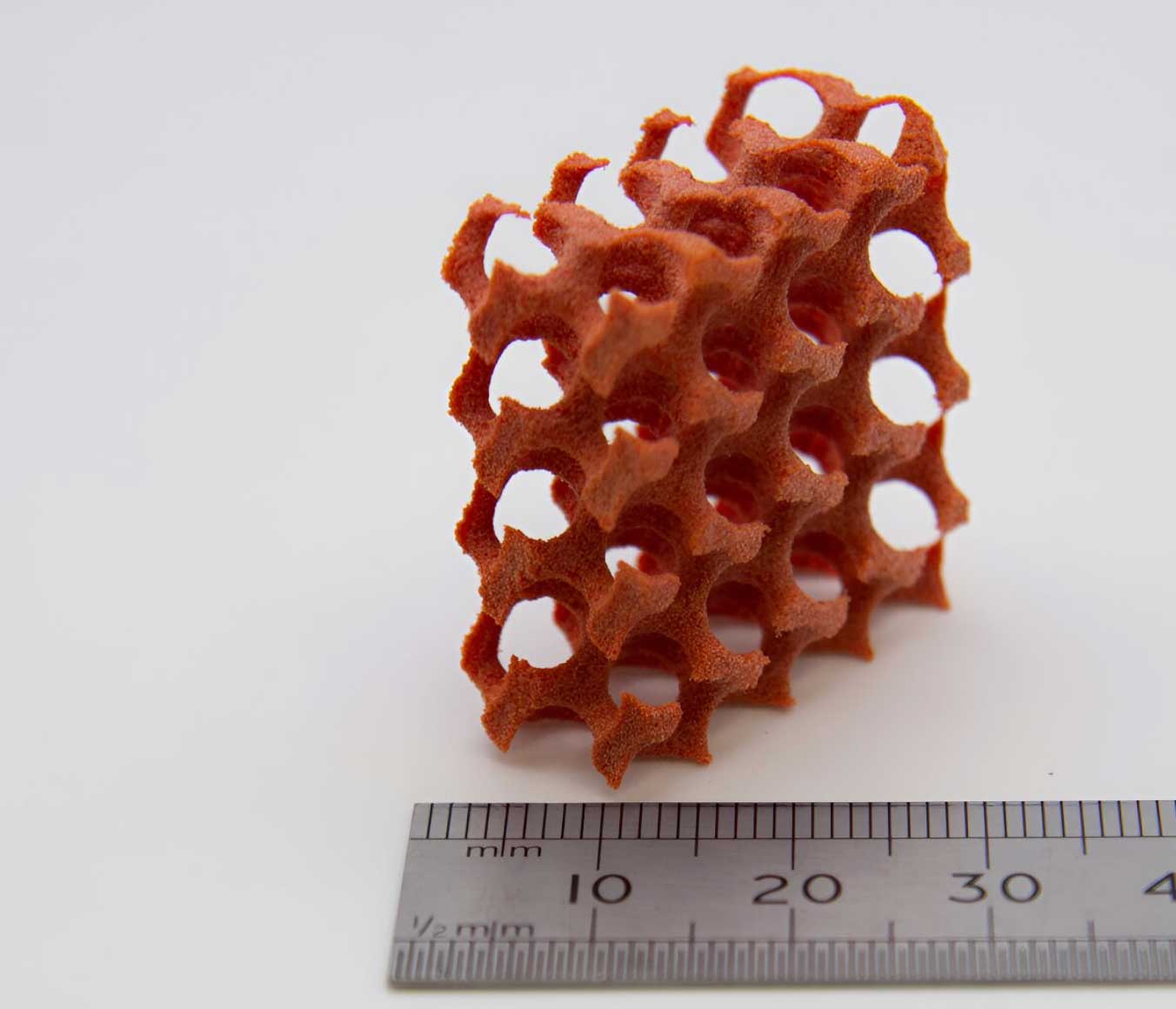

The researchers from the School of Chemistry and Engineering used supercritical carbon dioxide to develop an efficient, effective and environmentally friendly process for coating PA-12 polymer particles. These particles are used in one of the most common commercial 3D printing processes, powder bed fusion or laser sintering. In this process, a layer of free-flowing polymer powder is applied and fused layer by layer by a computer-controlled laser.

The new coating makes it possible to give the printed materials additional properties such as color and anti-mold and anti-fungal protection.

“The real benefit of 3D printing or additive manufacturing is in the design and production of bespoke and unique objects, but its limitations are in the materials and palette of available properties that limit the overall application space. This new process provides an easy route to the development of a wide range of material capabilities without compromising processability,” says Professor Christopher Tuck, professor of materials engineering in the Center for Additive Manufacturing in the Faculty of Engineering.

The research, published in Nature Communications, shows that the new process can be used to produce colored polymers that coat the PA-12 particles. This adds a variety of options to the previous color palette of gray and white.

“There are a few challenges facing the 3D printing industry due to limitations on the functionality of the polymers used. To tackle some of these challenges we have created a simple but effective approach to adding functionality by coating the particles. We’ve designed the colored shell polymer so that it matches the mechanical and thermal properties of the printing polymer. Most importantly we’ve demonstrated this with the key polymer (PA-12) that is ubiquitous to the industry. Our new colored polymeric powders work perfectly in the existing commercially deployed machines,” says Professor Steve Howdle, head of the School of Chemistry.

Currently, objects made from PA-12 cannot be used in humid environments as they are susceptible to mold and fungi. The new shell coating can also be used to develop coatings that prevent this, opening up new applications for 3D printed objects in a variety of fields.

Professor Howdle adds, “A key benefit of this process is that it can easily be incorporated into current commercial 3D printing processes and this could be potentially transformative for the industry in widening scope by introducing new functionality, simplifying processes and importantly achieving all of this sustainably.”

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.