Additive manufacturing technology, particularly in the field of 3D printing, is undergoing significant further development with the introduction of Printdur HCT, a new tool steel. Developed by the Swiss Steel Group, Printdur HCT is based on the conventional standard tool steel 1.2083 / AISI420, but is specially optimized for the requirements of powder bed fusion, as in AddUp’s FormUp 350.

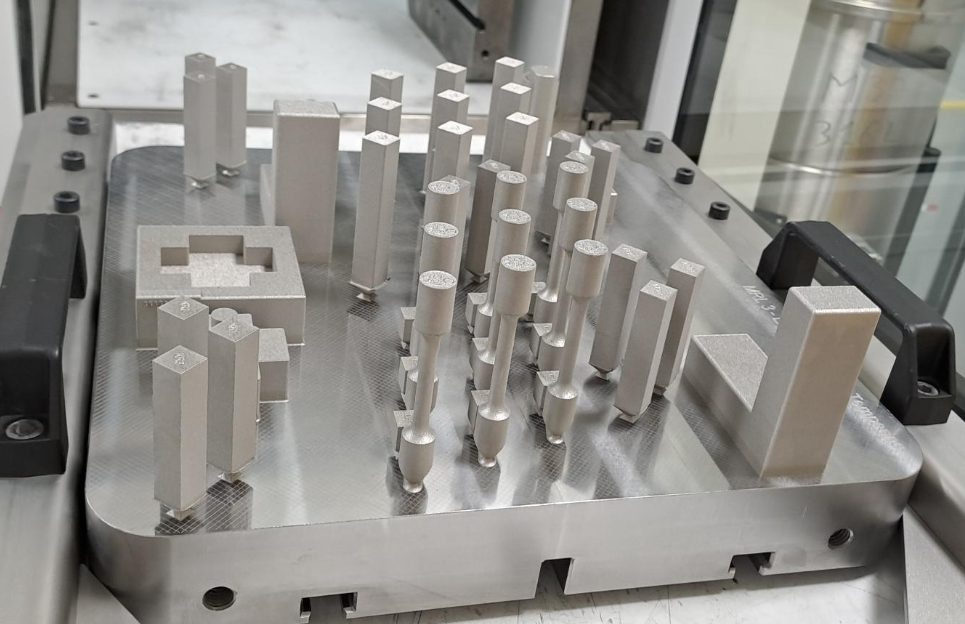

The special feature of Printdur HCT lies in its exceptional adaptation to additive manufacturing. This has enabled the engineers at AddUp, a pioneer in 3D printing technology, to achieve up to 50% faster build speeds compared to conventional materials. This increase in productivity does not come at the expense of quality: the material has extremely low porosity and a density of over 99.90%. These properties make it possible to produce surfaces of outstanding quality without leaving any smoke residue.

Dr. Horst Hill, Head of Special Materials at SSG, says: “Our goal is to use our decades of experience in atomization and materials technology to develop new materials for additive manufacturing. The Printdur HCT utilizes the advantages of additive manufacturing to achieve the best material properties. We are very pleased to have found a strong tooling partner in AddUp to bring new materials to the market.”

Another outstanding feature of Printdur HCT is its ability to significantly reduce production cycles. Massive time savings can be achieved in the injection molding process thanks to conformal cooling channels that can be produced in good quality without support structures. With a hardness range of 53-57 HRC and high wear resistance, Printdur HCT also offers an improved service life for the mold inserts.

In addition to these technical advantages, the Swiss Steel Group, winner of the German Sustainability Award, attaches great importance to environmental compatibility. A high standard of sustainability is achieved by dispensing with nickel and cobalt as well as a comprehensive powder recycling system.

Julien Marcilly, CEO of AddUp, said: “At AddUp, we are committed to taking tooling to the next level with the FormUp 350. Our company’s history is deeply rooted in the application of molds thanks to our founding partners Michelin and Fives. With our experience and expertise in this industry, we continue to push the possibilities of additive manufacturing and prove that it is a more efficient and productive way of industrial manufacturing.”

The introduction of Printdur HCT therefore represents a significant advance in additive manufacturing. It not only meets the technical requirements of modern injection molding, but also sets new standards in terms of efficiency and environmental compatibility.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.