Researchers at the Georgia Institute of Technology have developed a light-based process for printing nano-sized metal structures that is significantly faster and cheaper than any currently available technology.

The technology is based on 3D printing of metallic structures at the nanoscale, a key component for many technological advances, such as in electronics, solar energy conversion and sensor technology.

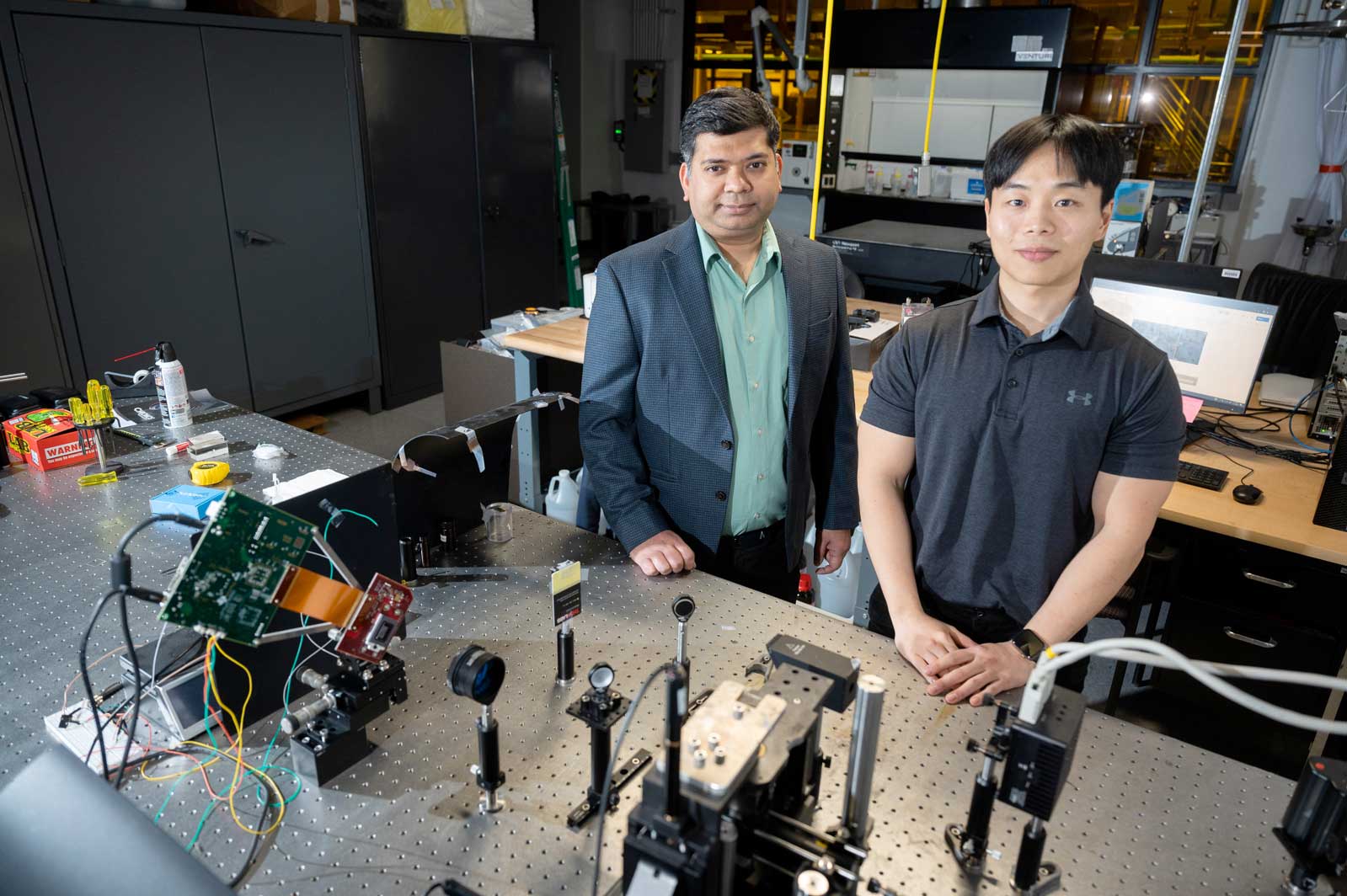

Sourabh Saha, assistant professor in the George W. Woodruff School of Mechanical Engineering, and Jungho Choi, a graduate student in Saha’s lab, developed a technique that is 480 times faster and 35 times cheaper than conventional methods. Their research results were published in the journal “Advanced Materials”.

It is usually assumed that high-intensity light sources are required for nanoprinting. However, femtosecond lasers that produce such light can cost up to half a million dollars, making them prohibitively expensive for most research labs and small businesses.

“As a scientific community, we don’t have the ability to make enough of these nanomaterials quickly and affordably, and that is why promising technologies often stay limited to the lab and don’t get translated into real-world applications,” Saha said. “The question we wanted to answer is, ‘Do we really need a high-intensity femtosecond laser to print on the nanoscale?’ Our hypothesis was that we don’t need that light source to get the type of printing we want.”

Saha and Choi were looking for a low-cost, low-intensity light source that could be focused similarly to femtosecond lasers and chose superluminescent light-emitting diodes (SLEDs), which are commercially available. SLEDs emit light that is a billion times less intense than that of femtosecond lasers.

They developed an original projection printing technology that converts digital images into optical images and displays them on a glass surface. The system works in a similar way to digital projectors, but produces sharper focused images. The unique properties of the superluminescent light enabled the creation of images with minimal errors.

The researchers also developed a clear ink solution made from metal salt and added chemicals to allow the liquid to absorb light. When light from their projection system hits the solution, it causes a chemical reaction that converts the salt into metal. The metal particles adhere to the glass surface and their agglomeration forms the nanostructures. As this is a projection type of printing, an entire structure can be printed at once rather than dot by dot, which speeds up the process considerably.

After testing, they found that the projection style of nanoprinting is also possible with low-intensity light, as long as the images are sharply focused. Saha and Choi believe that researchers can easily replicate their work with commercially available equipment. In contrast to an expensive femtosecond laser, the SLED type used by Saha and Choi in their printer costs around 3,000 dollars.

“At present, only top universities have access to these expensive technologies, and even then, they are located in shared facilities and are not always available,” Choi said. “We want to democratize the capability of nanoscale 3D printing, and we hope our research opens the door for greater access to this type of process at a low cost.”

This technique will be particularly useful for people working in the fields of electronics, optics and plasmonics, where multiple complex metallic nanostructures are required.

“I think the metrics of cost and speed have been greatly undervalued in the scientific community that works on fabrication and manufacturing of tiny structures,” Saha said. “In the real world, these metrics are important when it comes to translating discoveries from the lab to industry. Only when we have manufacturing techniques that take these metrics into account will we be able to fully leverage nanotechnology for societal benefit.”

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.