CAD/CAM CONSULTING SERVICES, INC. (CCCS), a provider of manufacturing software and hardware sales, service, support and training in Southern California and surrounding areas, has been named the newest distributor for Roboze‘s high-performance 3D printing solutions.

CCCS has been operating in the region since 1993, with offices in Anaheim, Newbury Park and San Diego. The company employs experienced professionals who are familiar with the region’s manufacturing landscape. The addition of Roboze allows CCCS to expand its additive manufacturing offerings.

Roboze’s 3D printing solutions address new markets and provide solutions to common problems such as process repeatability, accuracy and the need for high-performance materials such as super polymers and composites.

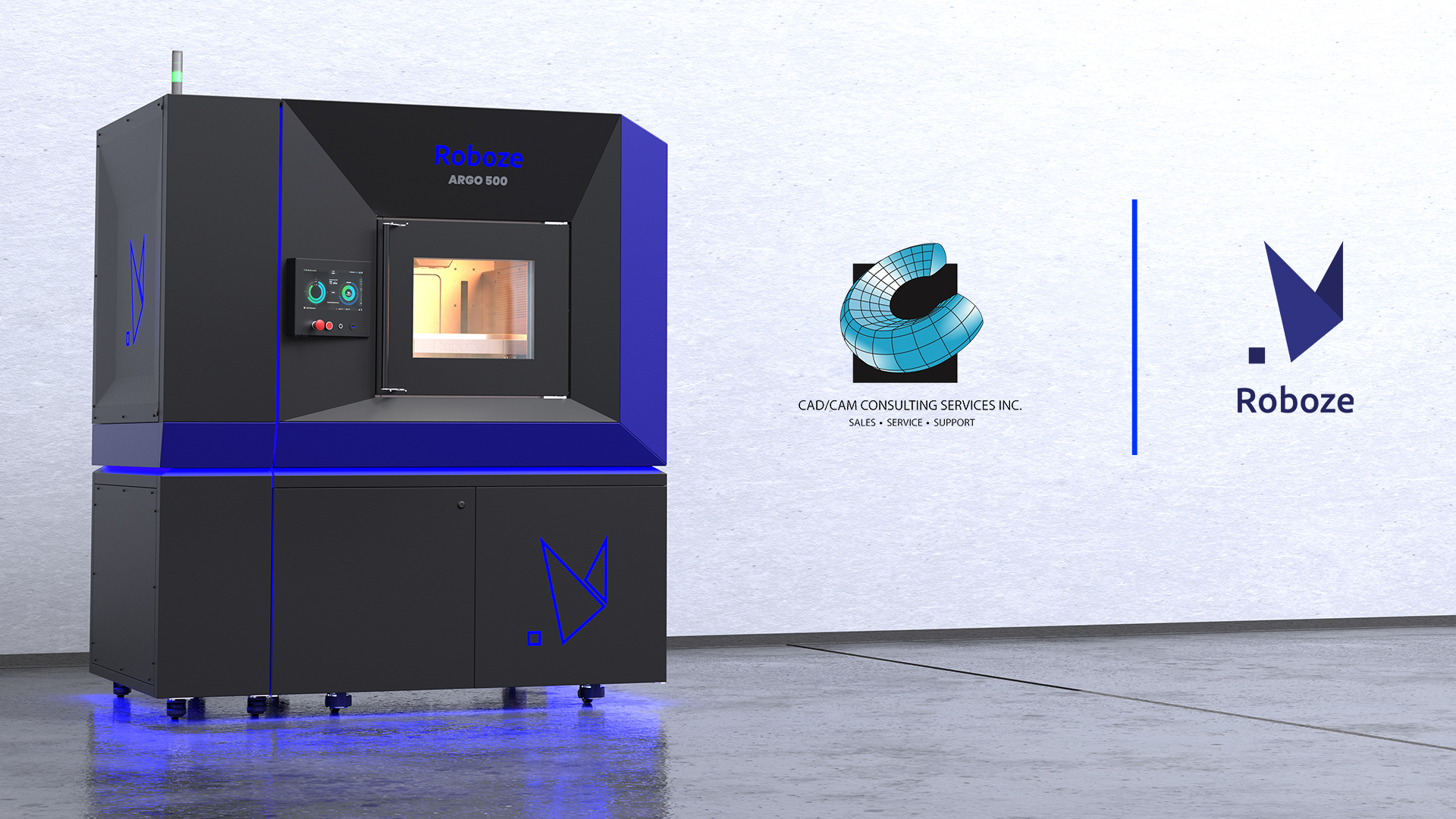

With the Roboze Plus PRO and Roboze Production Series (ARGO 500/1000), three levels of polymer-based materials, browser-based slicing creation software, and a proven model for service, support and training, the partnership between ROBOZE and CCCS is designed to help manufacturers optimize production processes and save resources.

Levi Smith, Global Director of Channel at Roboze: “At Roboze, we look for strategic partners who can extend our values and world class technical service and customer support. That is why I am extremely excited to announce our partnership with CAD/CAM CONSULTING SERVICES, INC. CCCS’ extensive knowledge in subtractive and metal additive manufacturing is well aligned to help customers navigate agnostic solutions to engineering problems. CCCS represents our first reseller in the Southern California market and their focus on localized manufacturing innovation is perfectly aligned with ROBOZE and our cutting-edge additive manufacturing solutions.”

Patrick Shelar, President of CCCS: “As we continue to look for new products that drive innovation that can be delivered to our customers, partnering with Roboze was an obvious choice. Their material portfolio and ability to print highly accurate large parts is a welcome solution for many companies that are trying to find new ways to lightweight their designs, cut down on lead times, and manufacture parts that simply cannot be traditionally machined. Additionally, their success overseas and vision for the future, along with their partnerships with high profile, high performing companies, ensures their trajectory as a disruptor in additive manufacturing. We are excited to be on this journey with them.”

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.