Shaary, a French based car sharing company, and XEV, a Chinese car manufacturer, specialised in 3D printed car components, have signed an agreement to bring 3D-printed electro mobility to Europe.

Christophe sapet, a famous French entrepreneur, established Shaary, an electric car sharing company, in 2018, believing that the future of mobility lies in sharing cars rather than owning one. When he learned that the new energy vehicles with 3D printed car parts from XEV can not only meet the needs of brand customization, but also rely on the unique service mode of interchangeable batteries in Europe, he determined that there was a need for a cooperation with XEV.

Henri Coron, the international director of the company, explained: “XEV has helped us achieve the purpose of brand customization with the help of 3D printing technology of Lobotics. Now the green cars with brand name ”Shaary” provided by our company with car sharing services may shuttle through every street in France, which makes our company vision of “being an electric urban travel expert without charging stations” become distinctive and popular.”

At the same time, Wesk announced that they would deploy its first car sharing service in two cities in France at the end of 2021.

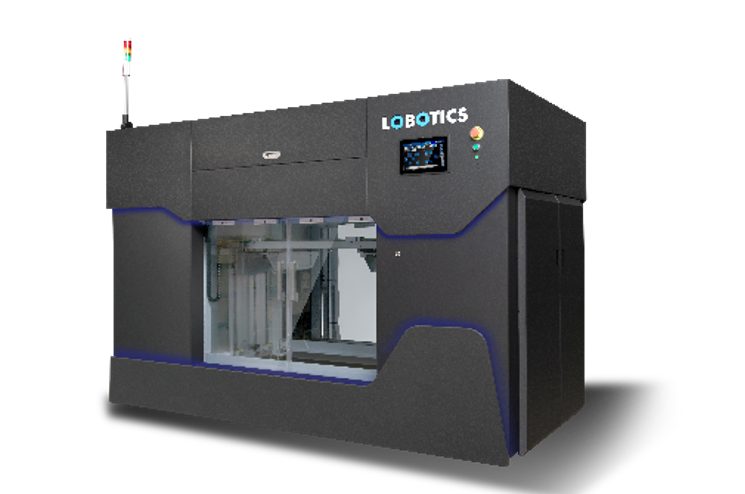

About 3D Printer AMPS1200

– Large-size printing parts: The 3D printer is designed according to the large-size printing parts of the automobile, which can make components of complete vehicles be realized through integral forming, and ensure the uniformity and aesthetics of the printing parts.

– The Most advanced Closed-loop liner motor: In addition, the printer adopts the most advanced closed-loop liner motor, which has the characteristics of higher motion accuracy, faster speed and acceleration, unlimited motion trajectory, which can fundamentally solve the motion accuracy of the equipment. The printing efficiency will be generally increased by 2 times, and the production capacity of printing materials will reach 5kg / day.

– Higher-performance materials: Higher-performance materials. Based on engineering plastics commonly used in industry, add different glass fiber, carbon fiber and other materials to greatly improve their mechanical strength, toughness, tension, compressive strength, weather resistance and oxidation resistance, and reduce its water absorption to better adapt to the characteristics of vehicles parts.

– More professional post processing: After the additive manufacturing and forming process, the parts need to be further processed to achieve the precision and surface finish required by the final parts. Our automated post processing working station is based on an anthropomorphic robot equipped with 8 automatic tool changers, such as Milling, grinding, positioning, dust collection and image acquisition that can achieve fully automatic milling and grinding and component accuracy control. The parts can meet the surface finish requirements of vehicles through the post processing. Through continuous testing, Lobotics has completed the development of fully automatic post processing and equipment, and will carry out localization upgrading.

– Smart production data mining system is an information collection system specially built for industrial users. It can realize real-time Data Acquisition, data collection and analysis, and it will adopt different analysis methods for different data to realize data information management and feedback the optimized data to smart production equipment during the printing, which can improve the printing quality.

– Design for Additive Manufacturing gives full play to the advantages of additive manufacturing technology during the process of parts design. Designing the structure of parts from multiple dimensions, such as multi-scale structure design, multi material design, internal filling structure design, etc. It can not only ensure molding, but also reduce material waste and improve surface quality, which is different from other equipment suppliers.

– Lobotics’s own material drying system can ensure that material is in a stable state for a long time, whether you are using the equipment or not. Lobotics understands the overall needs of plant equipment from users’ point and will focus on customer experience continuously.

More about Shaary: shaary.com

More about Xev: xev-global.com

More about Lobotics: lobotics-global.com

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.