Globally, over 50% of waste comes from construction and demolition work. Buildings and construction projects are responsible for 40% of greenhouse gas emissions, with the largest share of this emission coming from manufacturing raw materials, with packaging and transportation following closely.

These challenges are characterized by the following points:

- Reduce the environmental footprint of the construction sector

- Holistic consideration of the materials used over entire product cycle (selection of recyclable materials, reduction of materials used).

- Reduce construction cost and completion times

- Reduce arduous and risky physical labor.

This is where RiCHTER Lighting Technologies comes into play. Their project use cases range from creating parts that combine profiles into complex shapes to hold fabrics in our ceiling systems, to using 3D-printed parts to integrate into standardized architectural structures while maintaining the overall strength of the entire structure.

“As a manufacturing company, we at Richter Lighting Technologies GmbH are clear with our responsibilities and have been driving our main innovations, toward sustainable development of industrial solutions to meet the challenges of the construction sector

Bernd and Marion Richter, founders of RiCHTER Lighting Technologies GmbH.

Suspended Ceiling Systems

An example is their most recently completed project was the suspended ceiling systems in the lobbies of the 50 Hudson Yards building in New York City. They drew from their expertise in multiple fields, their experience from past projects, and leveraged some of the most innovative technologies to meet clients’ requirements.

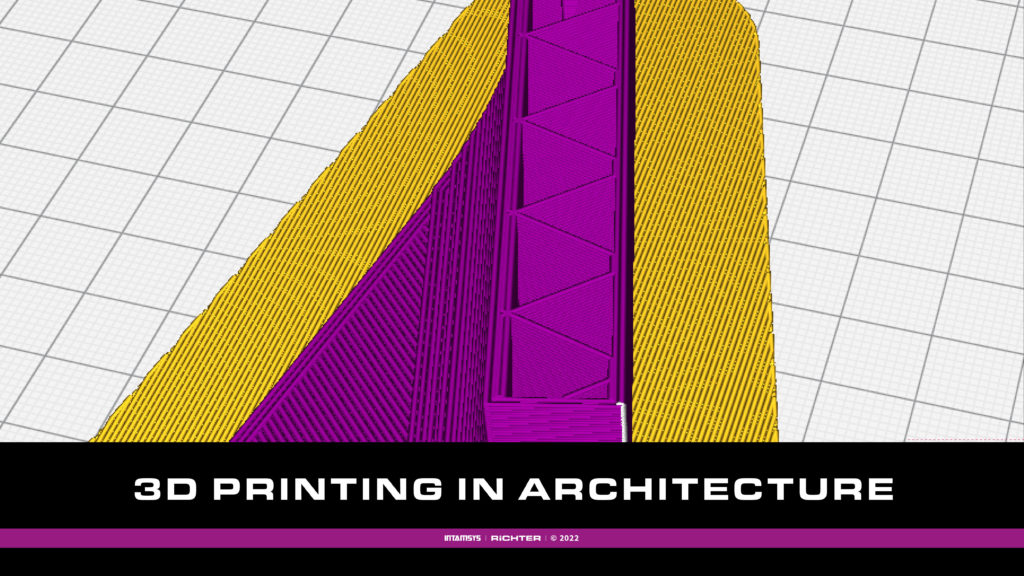

For this project, RiCHTER’s team needed to create complex components to combine multiple profiles for architectural structures and to hold their fabrics in the ceiling systems. To achieve this goal, they needed a material with specific properties, and a 3D printer that can get the best out of the materials.

The material that had the required properties was the ULTEM™ 9085 filament, a polyetherimide (PEI) plastic and the 3D printer used to achieve this task was the INTAMSYS FUNMAT PRO 610HT. It also has a controlled heated chamber, that was set to about 200 °C, which is necessary in order to achieve strong layer bonding for the ULTEM 9085 filament because of its glass transition temperature of 186° C. The printer has a nozzle temperature that goes up to 500 °C, adequate for this material because of its high melting point.

The result was:

- Very complex integrable shapes, that the concept of milling could not even be considered.

- Very durable components with strong layer bonding.

- Lightweight and highly flame-retardant components.

- Reduced materials with infill structure.

Unique architectural component

Another example is when they use the BASF Ultrafuse PC/ABS FR for their high-end architectural projects.

The major challenge for some projects was achieving a combination of different materials, assembled as a single piece, and shipped for easy, on-site installation.

This component had to have the following requirements:

- Remain invisible

- Excellent surface quality to act as a frame for fabric systems.

- High durability & flame retardant

They achieved this unique architectural component using innovative technologies like (3D printing, 3D engineering, etc.) and thanks to the philosophy at Richter Lighting Technologies GmbH.

Find out more about RiCHTER Lighting Technologies at richter-lt.de.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.