Complex cavities or recesses are often a challenge for 3D printers and require the use of support material. However, a YouTuber with the username MakerSpace has developed an innovative approach to realizing such structures without classic 3D printing supports – inspired by the sand casting process.

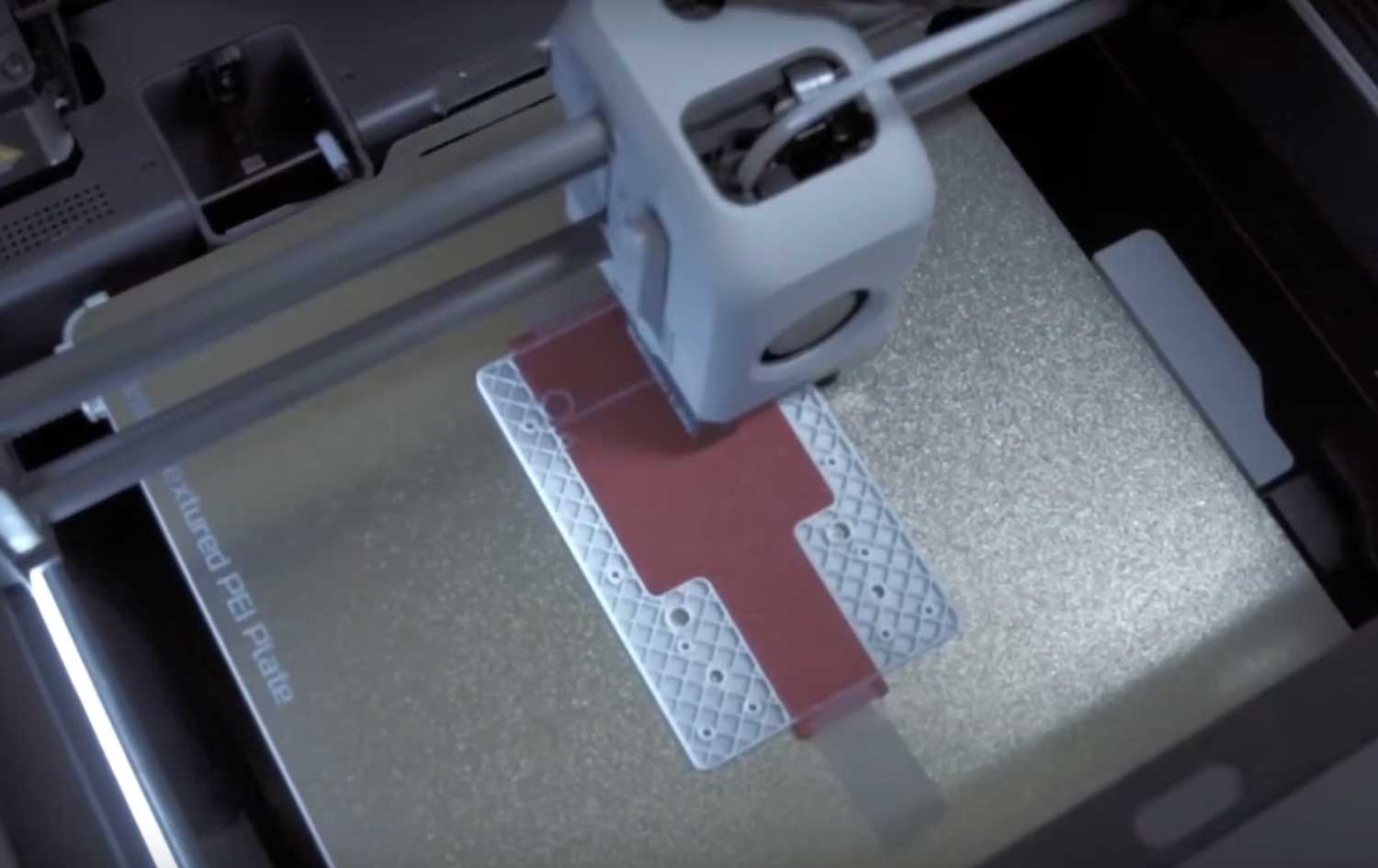

The aim was to 3D print an RFID card holder with a slot on one side and cut-outs for the antenna on the other. Instead of filling the entire complex shape with support material, MakerSpace first printed a detachable “core” made of PETG filament.

During the subsequent printing of the actual PLA object, a pause is made after the first layers, the PETG core is inserted and the printing process continues. The core thus serves as a temporary support material for the cavities and overhangs. Once printing is complete, the core can be easily removed from the PLA print thanks to the different material properties.

To prevent the PLA from sticking to the PETG core, MakerSpace applied a release layer as a release agent. A small protrusion on the core also made it easier to insert into the print and remove later. With this method, very clean results can be achieved without support material residues in cavities.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.