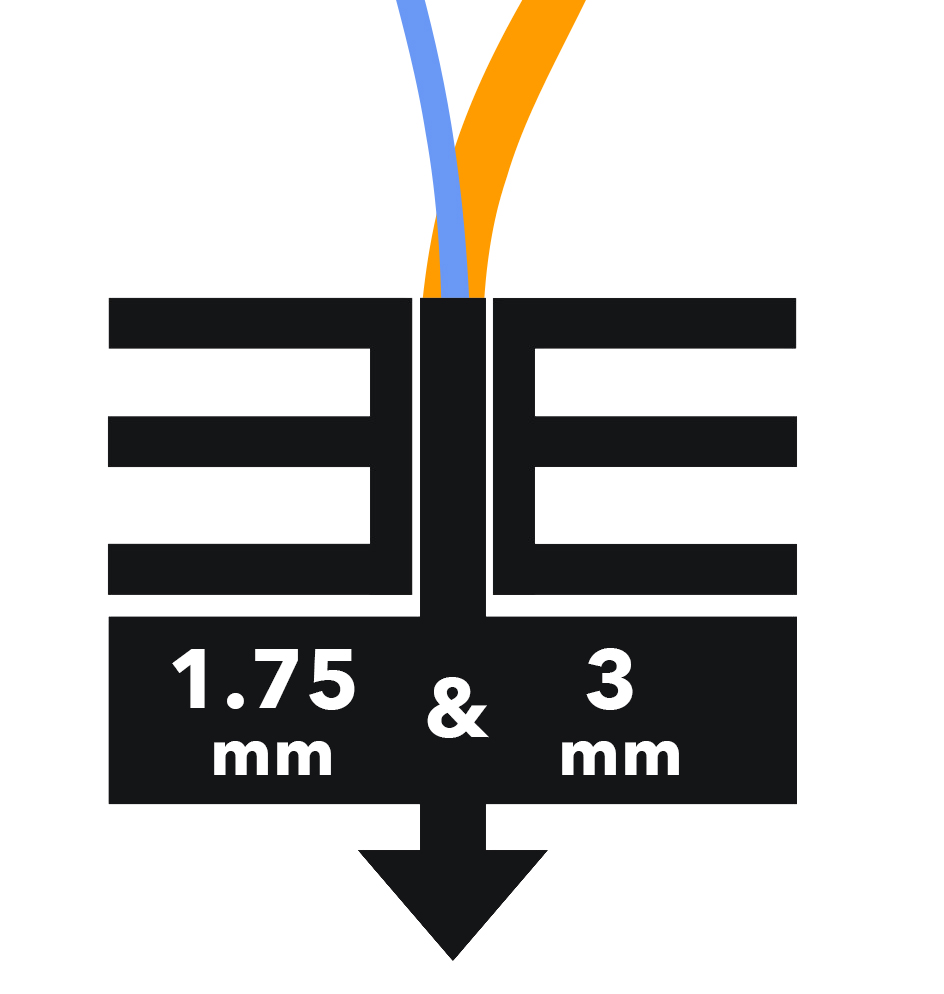

ReprapUniverse and Kai Parthy have solved one of the biggest dilemmas of 3D printing. Before buying a 3D-printer you always have to make a fundamental decision. Namely, with which filament in the next few years you want to print with: 1.75 mm or 3 mm?

January 4th 2016 – As of today, this is a thing of the past.

Richard and Franz Achatz of RRU and Kai Parthy announce a groundbreaking modular Full Metal Hotend coming soon to the market .

This Hotend may print with two standard filament diameters. The change of 1.75 mm to 3.0 mm is made in less than 5 minutes, and requires only a change of truly novel filament-nozzle.

Franz Achatz: ” We simply had no choice and call it therefore quite simply 1730Hotend”

Key Features:

Printing 1.75 and 3 mm Filament

Printing 1.75 and 3 mm Filament

The 1730 Full Metal Hotend enables switching Nozzles between 1.75 mm and 3 mm in less than 5 minutes*. Experience total 3D-Printing freedom and enjoy the best of both worlds.- Modular Full Metal Hotend

1730’s innovative modular setup makes it a direct driven and bowden Hotend all in one. Nozzles are easily and quickly changed. A Hotend designed to be universal. - High Performance Printing

The 1730 Full Metal Hotend is optimized for printing PLA, ABS, PU, PC and exotic filaments. Extensive research and prototyping have resulted in a unique thermal handling which provides an unparalleled 3D-printing experience.

Further Features:

- Optimized thermal barrier. Water cooling is not necessary.

- Very short heating zone inside the extra-long nozzle.

- The 1730 Full Metal Hotend is physically leakage proof and not using any PEEK or PTFE tubing.

- Reduced feeding friction which is optimal for soft and brittle materials (e.g. PU).

- Effective use of energy. Short heating-up time.

- Very easy z-leveling for dual-extrusion

- 500 °C tested expert module will be available in future as add-on.

- With the 1730 Full Metal Hotend we have achieved shorter retract values.

- This greatly improves overal printing speed.

- The 1730 Full Metal Hotend comes fully assembled. Just mount it and start printing.

- Mounts / adapters will be available from the start for a variety of 3D-Printer Models: Reprap 3D-Printers with Greg’s Wade Extruder, Delta 3D-Printers, GRRF (German Reprap) and 3D-Printers which have already mounted a J-Head or E3D Hotend. More mounts / adapters for other 3D-Printers will be available in the future.

Story:

The 1730 Fullmetal Hotend is realized through cooperation between the filament developer Kai Parthy and the team behind 3D printer manufacturer ReprapUniverse (Franz and Richard Achatz). Both companies share more than 10 years and longer experience in the 3D printing industry.

Hotend history of Kai Parthy:

As filament developer I have of course always ideas, how a hotend should be designed to achieve better printing results with exotic filaments.

My first idea for a hotend has become a widely used standard.

The multi-filament hotend: two filaments are simultaneously or alternating pushed in the hotend.

Another hotend, which is a smart hotend, idea is due to lack of investors still in the concept stage

The 1730hotend

came in search of a solution for thermal problems that arise in commercial ful metal hotends. Together with the team of ReprapUniverse we have built and tested dozens of prototypes. In these tests, the 1730 surpassed my initial expectations. It has the potential to set new standards as a consumer-friendly hotend.

*Filament change: Based on universal extruder design.

Why Kai Parthy continues to focus on 3.0 mm?

Some believe that 3.0 mm filaments are no longer manufactured in the near future . This is nonsense . There are filaments , which can due technical reasons not produced in 3mm , some materials may not be pushed in a hotend, as a 1.7 mm filament, (eg . the soft PU’s ). The 3 mm filament market share in Europe remains at about 35 % .

January 26th 2016 – Update: 1730 hits Kickstarter

The Kickstarter campaign for the flexible hot end just started. You can be one of the first to get a 1730 hot end for using 1.75mm and 3mm filament.

For just 79€ you´ll get a 1730 hot end with either a set of different 1.75mm brass nozzles or 3mm brass nozzles. These nozzles are 0.25mm, 0.3mm, 0.4mm and 0.6mm.

For 129€ you get a fully assembled 1730 full metal hot end with a 0.4mm nozzle for 1.75mm and one for 3mm filament.

Check out the Kickstarter page for the 1730 hot end!

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.