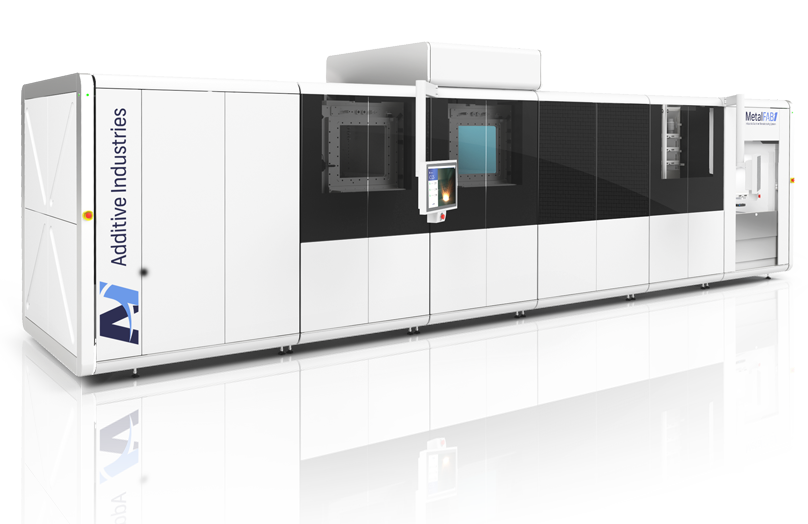

The Eindhoven-based company Additive Industries, has announced the launch of its industrial metal 3D printing system MetalFAB1 at the formnext, taking place in Frankfurt this November.

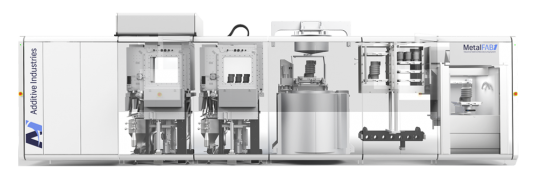

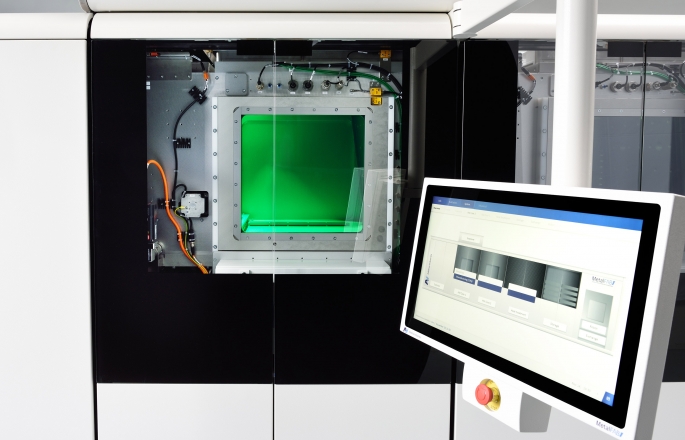

October 19, 2015: The team of Additive Industries has been working on the industrial-grade system based on metal powder bed fusion technology since 2012. MetalFAB1 is a modular system with features such as multiple full field lasers, continuous in-process calibration and integrated heat treatment. Alongside, Additive Industries has developed a software platform that not only supports 3D printing process management, but also request handling, simulation, in-process quality control and infrastructure monitoring.

The metal 3D printing system has first been announced in November last year, with further details revealed at RAPID 2015.

Daan Kersten, CEO of Additive Industries: “Last year we exhibited in Frankfurt with a large wooden machine crate and promised to launch our industrial 3D metal printing system in Frankfurt this year. Now we are fulfilling our promise and we are planning to show how future Additive Manufacturing will look like and rock the show.”

November 17, 2015: Update – MetalFAB1 System unveiled

Additive Industries has officially unveiled their MetalFAB1 3D printer, a system offering 10 x better reproducibility, productivity and flexibility compared to typical midrange systems.

This performance is achieved by the machine’s robust and thermally optimised equipment design, smart feedback control and calibration strategies, elimination of waiting time along with automation of build plate and product handling. Its modular design allows for application-specific process configuration tailored to the customer’s needs. Up to four materials can be handled simultaneously in multiple build chambers, each with a build envelope of 420 x 420 x 400 mm with individual integrated powder handling. The system also includes a furnace for integrated stress relief heat treatment.

Additive Industries will start its Beta test programme next month and four Beta machines have already been reserved by customers from demanding markets like aerospace, high tech equipment and tooling.

“We are eager to work closely together with our Beta customers. We will team up to further develop the process, new materials and applications as well as testing the performance to substantially improve the business cases of our customers“, said Daan Kersten, co-founder and CEO of Additive Industries.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.