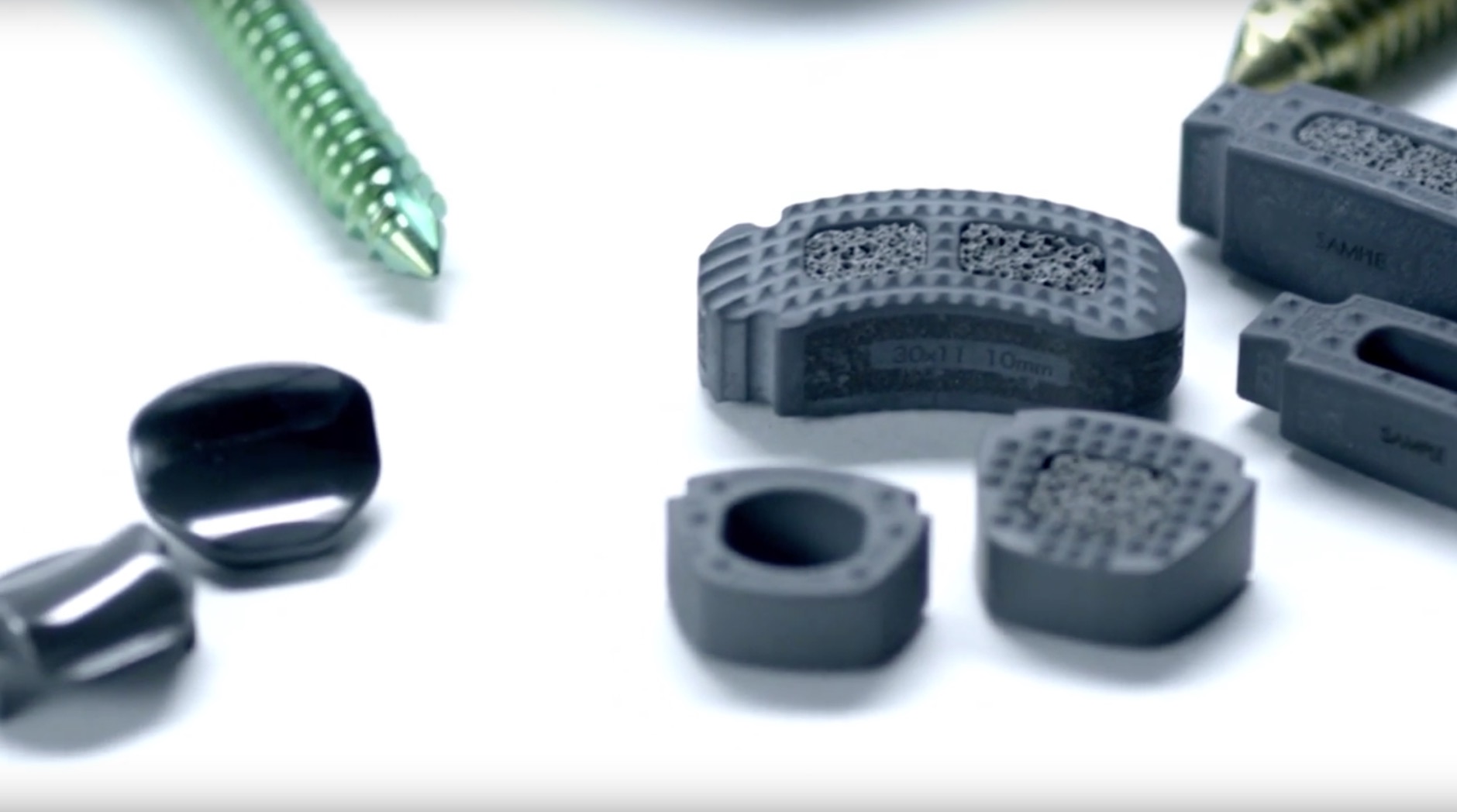

Amedica, a company developing implants manufactured with silicon nitride ceramic material, has announced its first fabrication of complex structures using a 3D printing process called robotic deposition or robocasting.

Examinations using scanning electron microscopy confirmed that the 3D printing process achieves similar density and microstructure attributes as traditional methods for creating silicon nitride fusion devices. The binder-less process is based on layered deposition of highly colloidal slurries. Objects can be completely sintered in less than 24 hours. Robocasting allows for creating silicon nitride implants with controllable porosity levels enabling bone ingrowth in areas needed. Additionally, bone scaffolds suited for cellular differentiation and neovascularisation can be printed.

Dr. Sonny Bal, Chairman and Chief Executive Officer at Amedica said in a press release: “This innovation speaks to the unique art and science related to our manufacturing strength. 3D printing of a complex ceramic material opens future doors, especially in terms of cost advantages, and addressing a variety of OEM partner needs. Custom additive manufacturing is a modern advancement, and we are proud to lead the way in 3D printing of our silicon nitride formulation, with its advantages in bone fusion, antibacterial behavior, and superior strength.”

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.