California based Startup Carbon3D unveiled their groundbreaking and incredibly fast 3D printing technology at the TED2015 conference in Vancouver yesterday.

Called Continuous Liquid Interface Production (CLIP) Technology, the new 3D printing method grows objects in a resin tank at a speed of 25 to 100 times faster than other current 3D printing methods. But it does not stop there. Parts produced feature consistent mechanical properties with a layerless, smooth surface and solid inside.

So how exactly does this new technology work?

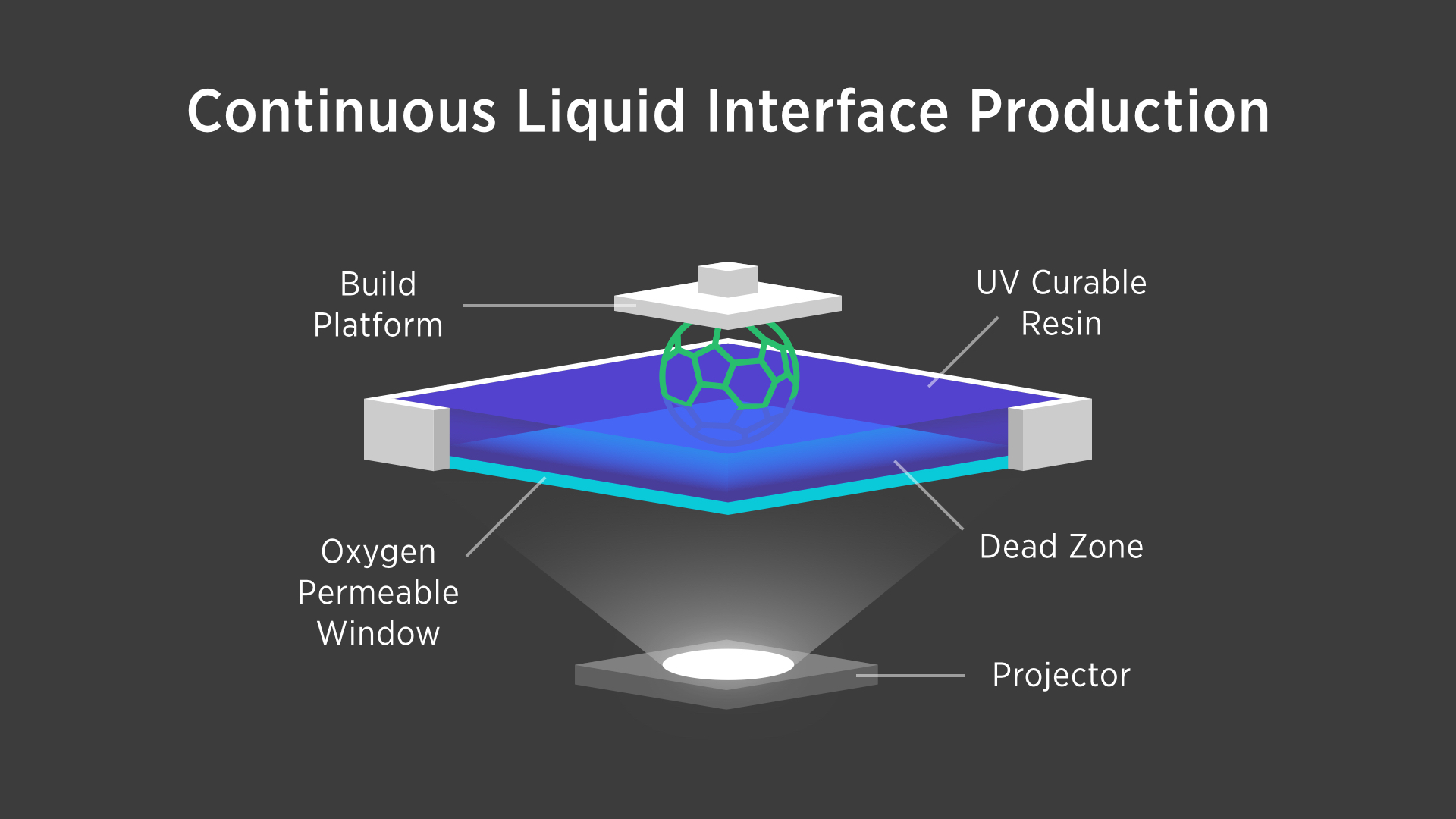

Using a “tunable photochemical process” the object is created by carefully balancing the interaction of UV light and oxygen in a tank of resin. UV light cures the liquid polymer in a process called photopolymerisation, while oxygen inhibits the reaction. The bottom of the resin tank, the so called “window”, is transparent to light and permeable to oxygen, just like a contact lens. The flow of oxygen creates a “dead zone” at the very bottom, inhibiting photopolymerisation, so the object can grow continuously while being drawn from the tank.

“Current 3D printing technology has failed to deliver on its promise to revolutionize manufacturing,” said Dr. Joseph DeSimone, CEO and Co-Founder, Carbon3D. “Our CLIP technology offers the game-changing speed, consistent mechanical properties and choice of materials required for complex commercial quality parts.”

Carbon 3D has released several videos, demonstrating their proprietary CLIP Technology. In the following video you can see how an Eiffel Tower is created within 7 minutes:

Demo of CLIP Technology (7x speed):

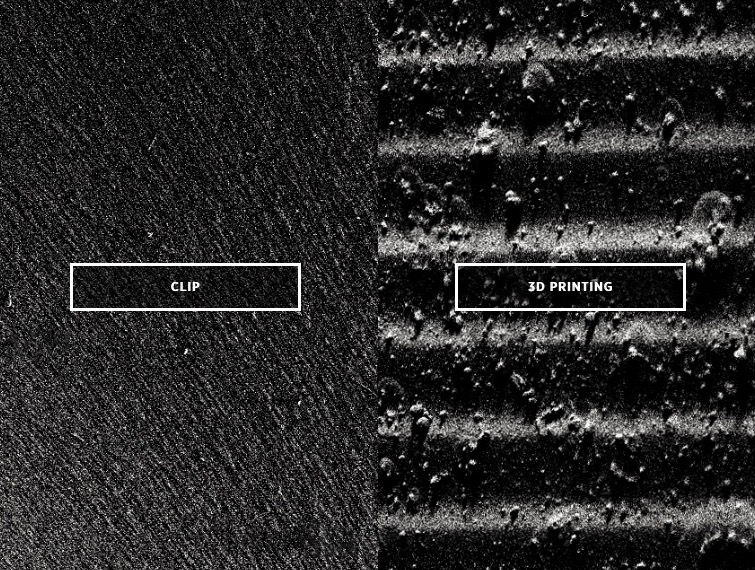

Following pictures compare the surface results of an object created with CLIP compared to a layer-by-layer 3D printing process:

Since its founding in 2013, Carbon3D has secured $ 40 million in series A and B funding, led by Sequoia Capital and Silver Lake.

“If 3D printing hopes to break out of the prototyping niche it has been trapped in for decades, we need to find a disruptive technology that attacks the problem from a fresh perspective and addresses 3D printing’s fundamental weaknesses,” said Jim Goetz, Carbon3D board member and Sequoia partner. “When we met Joe and saw what his team had invented, it was immediately clear to us that 3D printing would never be the same.”

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.