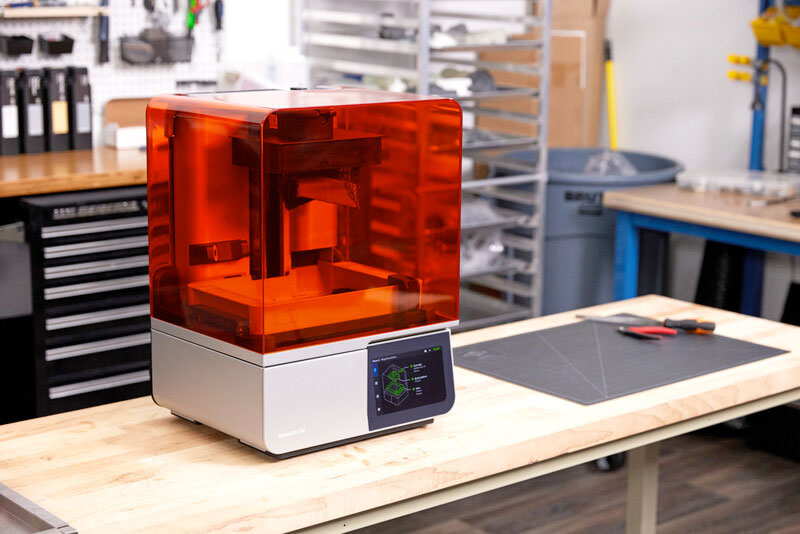

With the Form 4, Formlabs is launching its fourth generation of desktop SLA 3D printers. The new printer is said to set new standards in terms of speed, reliability and user-friendliness thanks to its specially developed Low Force Display (LFD) printing system, new high-performance resins and automation functions.

The key to the increased print rates is masked stereolithography (MSLA). According to the manufacturer, printing times are two to five times shorter than with the previous Form 3+ model. Small parts can be produced in minutes, while large batch sizes can be produced at vertical speeds of up to 100 mm/h.

“The Form 4 is a huge step forward not only for Formlabs and our customers, but for the entire 3D printing industry,” says Formlabs’ CEO and co-founder Max Lobovsky. “More than a decade ago, Formlabs created the category of desktop SLA printing, setting a new standard in 3D printing for accuracy, reliability, ease of use and affordability. Based on the knowledge and experience of over 130,000 SLA printers sold and over 300 million parts printed by our users, we have developed our best SLA printer ever, the Form 4. Its reliability and unparalleled speed will help our customers revolutionize their product development.”

The LFD system includes a special, extremely powerful lighting unit, a release texture in the resin tank and an innovative, flexible double film tank. In combination with temperature controls, force and deposition sensors, this should enable the highest print reliability in the industry.

Thanks to 50 micron pixel size, highly collimated light and advanced edge smoothing, Formlabs promises excellent surface quality and tight fits. Other aspects such as fast material resin changeover, automatic post-processing and quick-release plates should ensure an intuitive workflow.

Compared to its predecessor, individual part costs are said to be up to 40 percent lower. Cost drivers such as the more frequent replacement of wearing parts have been reduced. For example, the resin tanks are expected to last over 75,000 layers and the lighting unit over 1 million.

Along with the Form 4, Formlabs is introducing six new standard resins that take advantage of faster printing. In addition, 17 further high-performance resins are certified, for example for dental printing. With the derived Form 4B model, Formlabs is specifically targeting manufacturers of biocompatible medical products.

The Form 4 is now available for 4349 euros and the Form 4B for 6099 euros.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.