Two industrial design students from Philadelphia University have come up with a solution for a completely custom footwear.

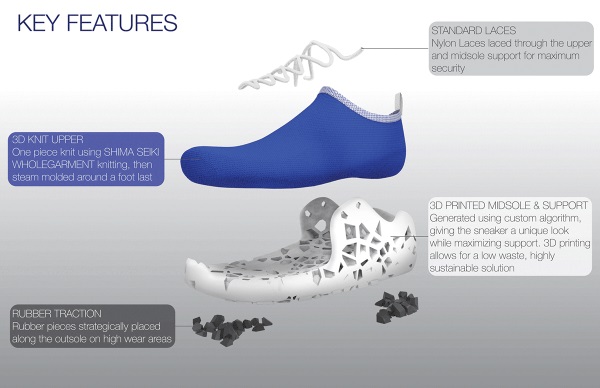

Called FOOTPRINT, the concept features a 3D printed custom algorithmic footwear created with the aid of 3D scanning, algorithmic models and software along with 3D printing technology.

Motivated by the frustration of standardised shoewear, Matt Flail and Tim Ganter started their project by breaking down the manufacturing process and getting feedback from podiatrists about common problems and optimal fits.

Podiatrist Davison de Queiroz explains: “The biggest issue is the difficulty of fitting the orthotic correctly into the sneaker. The orthotic could be built correctly and fit the foot perfectly, but if it does not fit in the sneaker correctly it can do more harm than good.”

So they wanted to come up with a completely customised shoe, that adjusts to the wearer’s foot. After performing a 3D scan of the foot, an exact 3D model is created which can then be used with algorithmic 3D modelling software to design the cellular structured footbed and midsole. First tests for 3D printing were performed on an FDM device using NinjaFlex filament. The team has then decided to turn to Selective Laser Sintering (SLS) technology for their final prototype and following production. The upper part is created with an automated WHOLEGARMENT process, that knits it seamlessly in one piece.

While Matt and Tim are currently working on perfecting their concept, companies like SOLS or RS print have already successfully launched their custom 3D printed insoles.

Following short video shows the final prototype of FOOTPRINT:

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.