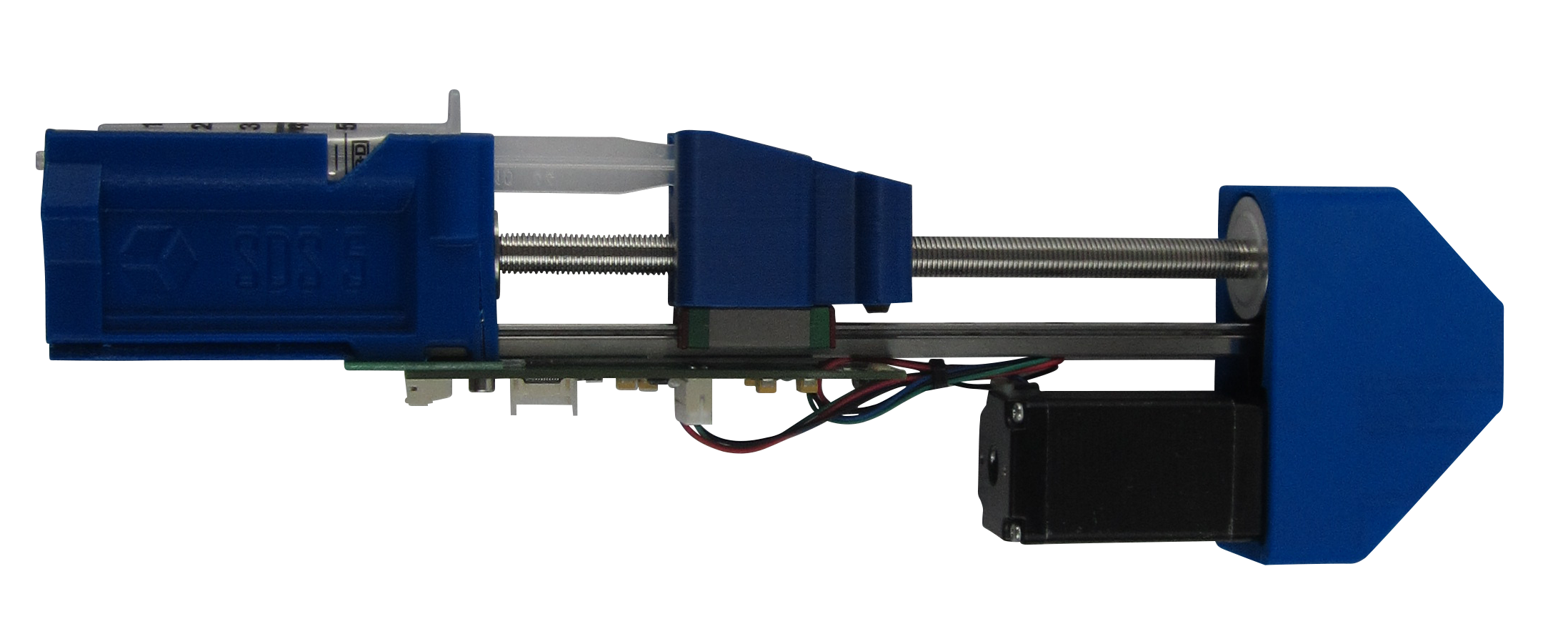

Georgia-based company Hyrel 3D has launched the Syringe Delivery System (SDS) line of extruders, allowing users to print materials directly from syringes using the Hyrel 3D system.

According to Hyrel 3D there are no limitations on the types of materials that can be loaded into the syringes. Moreover, they can easily be filled, swapped and stored by the user, which could “mean the end of monopolies on material supply chains by 3D printing companies” Hyrel says. Besides bioprinting gels and other liquids, SDS can also be used for applications in mechanical and electronics fields (e.g. for conductive pastes and liquids). Each extruder head has local intelligent control via Canbus and Micro-Controller.

The SDS line of extruders support syringes in sizes ranging from 100 microliters to 60cc. Up to four SDS extruders can be loaded on a Hyrel System 30M, which allows layering and gradient prints that were previously impossible. Materials and ratios can be mixed and matched on demand.

“The SDS opens up the unrestricted sourcing of chemicals for 3D printing — you’re no longer restricted to what suppliers will sell you,” Hyrel Chief Technology Office Karl Gifford said. “It’s ideal for people that want to develop cost-effective applications in numerous fields.”

Prices for the extruders start at $ 400 for a basic single print head. The Quad-extrusion print head compatible with micro-fluidic mixing chips start at $ 2,500.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.