3D printing has been one of the most talked-about technologies of the last few years. Now, Verbatim has entered the market and here, Matthias Breuer, Key Account Manager, of Verbatim in Germany, talks about the background to the decision, and what the company will bring to the market.

You entered the 3D printing market last year, which took many in the industry by surprise as it’s not a market anyone would associate with Verbatim. What’s the background to the decision?

Our parent company, Mitsubishi Chemical Corporation, is one of the largest chemical companies worldwide with extensive experience and expertise in the field of polymers. Many people associate Verbatim with optical storage media, which is one of many uses of polymers and 3D printing also makes use of polymers. In fact, we have access to over 12,000 types of plastic that can be used for 3D printing. Our parent company saw that we have an excellent distribution network throughout the world, and that we have enjoyed considerable success with optical storage media, so it was natural that we would enter the 3D market on Mitsubishi’s behalf, providing the sales and marketing front end capability for our parent company’s research and development back end.

Verbatim is offering its own unique solution for 3D printing. What is that?

Verbatim is offering its own unique solution for 3D printing. What is that?

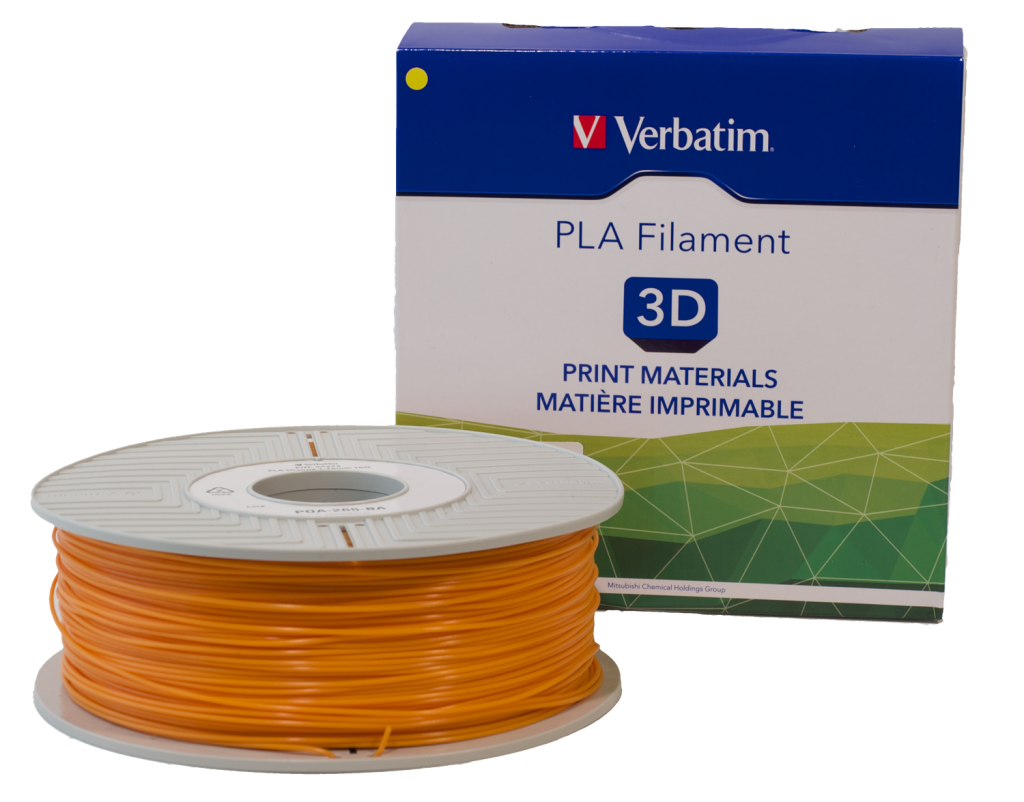

Of course, we offer ABS (acrylonitrile butadiene styrene) and PLA (polylactic acid) because those are industry standard materials and our offering is recognised by customers for its high quality. It is, of course, subject to the quality controls that Verbatim is renowned for.

But to succeed in this market – which is what we plan to do, of course – we believe that we need to offer something different, something unique in addition to industry standard materials.

It’s called PRIMALLOY and it’s a very flexible, rubber-like material of which there aren’t yet many in the market. It’s a thermoplastic elastomer (TPE) which consists of a crystalline aromatic polyester block (mainly PBT) as the hard segment, and an uncrystalline polyether block (mainly poly-tetramethylene-ether-glycol) as the soft segment. By comparison with standard TPE materials, PRIMALLOY offers more flexibility and a rubber-like elasticity. Its key features include good mechanical strength, oil resistance, chemical resistance, flex fatigue resistance and excellent heat resistance, as well as hardness stability within a wide temperature range. These features make PRIMALLOY a very attractive material for 3D printing.

We’ll be introducing additional new 3D printing materials in the near future.

What kind of applications do you envisage for PRIMALLOY?

It’s ideally suited for the automotive sector, in applications such as door locks or protective sheaths for electrical connections. There are many other applications for which we think it will be an excellent fit, such as toothbrushes, goggles and buttons, or it could be used for creating handling grips for electrical items like power tools or consumer devices like mobile phones.

Why would a customer buy from Verbatim rather than another manufacturer?

The first reason would be because a customer would recognise that the Verbatim name is synonymous with quality. We have a truly outstanding reputation for being a reliable, trusted brand. That quality isn’t just in our products, either. It is also there in our customer support, our relationships with retailers, our management of logistics and so on.

That alone distinguishes us because, inevitably, a market that is growing as rapidly as the 3D printing market is, and the size to which that market is forecast to grow, is attracting plenty of entrants and the majority of them are companies you’ve never heard of, with no track record.

But we don’t expect to succeed just on the basis of our reputation. We know that we also have to offer products that are demonstrably superior.

Verbatim’s filaments are manufactured from the highest quality materials and produced to extremely tight tolerances (+-0.02 mm) to ensure consistent feed and stable printing results. Furthermore, our filaments are delivered in a vacuum bag, with desiccant, wound onto a bespoke Verbatim reel which has been designed for robustness, uniform dynamic performance and failure-free operation.

Customers will, we believe, also buy from us because we have excellent compatibility with the 3D printing systems out there. Part of our backup support is that we maintain on our website a list – which is always up-to-date – of the systems with which our offering is compatible.

And as if our reputation, excellent customer service, outstanding product quality and wide-ranging compatibility weren’t enough reasons to buy from Verbatim, we also offer choice. We currently offer over 50 products in a range of bright colours and in two optional diameters across our ABS, PLA and PRIMALLOY range.

You talk about Verbatim’s reputation for quality products. Why is that important in the 3D printing market?

For a printed object to be strong and accurately formed, it is crucial that the printer knows exactly how much plastic it is pulling through the machine at any given time. The precision of the filament diameter and the roundness of the filament (the closeness of tolerance) is a vital measurement in ensuring reliable printing. Verbatim’s filaments are manufactured from the highest quality materials and produced to extremely tight tolerances to ensure consistent feed and stable printing.

Verbatim has changed its packaging design. Why is that?

Although it has been around for several years – it first started to come to prominence in the 1990s – in real terms, 3D printing is still in its infancy. That means that it’s mostly used for what you might call professional applications by organisations such as universities and colleges and research institutes as well as in the commercial and manufacturing sectors.

An advantage that Verbatim brings, however, is that we are both a B2B and a B2C company. What we see, as the 3D printing market continues to grow, is that materials for 3D printing will become available through the retail channel and our packaging needs to reflect that shift and be more consumer-friendly. That means, for example, highlighting the consumer-trusted brand name Verbatim; making the packaging easy to handle; and including an EAN code on the front.

You talk about the current B2B market for 3D printing becoming both a B2B and a B2C market. Can you expand on that?

It’s important to understand how rapidly this market will grow. Gartner, for example, estimates that, from around 110,000 3D printing units sold in 2014 at a value of over €500 million, more than 2.3 million units will be sold in 2018.

But yes, as I mentioned, it is currently a market dominated by professional applications: that means that the B2B market represents around 80% of the demand.

The other 20% comprises those who love technology and/or are early adopters of technology. For the mainstream consumer market, though, 3D printing is not yet sufficiently plug’n’play. Until it is, it won’t really be a consumer market but we’re convinced that will happen.

Near term, the market will continue to be predominantly a B2B market, and that’s where we and Mitsubishi are focusing our efforts with PLA, ABS, PRIMALLOY and other materials we will be introducing.

The developments we see really helping to drive the 3D printing market are, first, higher speed printing; second, the ability to print in multiple colours (something that will be really important to the consumer market): and third, greater diversity of materials to expand the possible applications of the technology.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.