Filament manufacturer Polymaker unveils Polymaker PC, a new line of polycarbonate-based materials specifically designed for extrusion-based desktop 3D printers.

To date, polycarbonate has only been available to those with expensive industrial 3D printers, or a very niche set of extrusion-based desktop 3D printers.

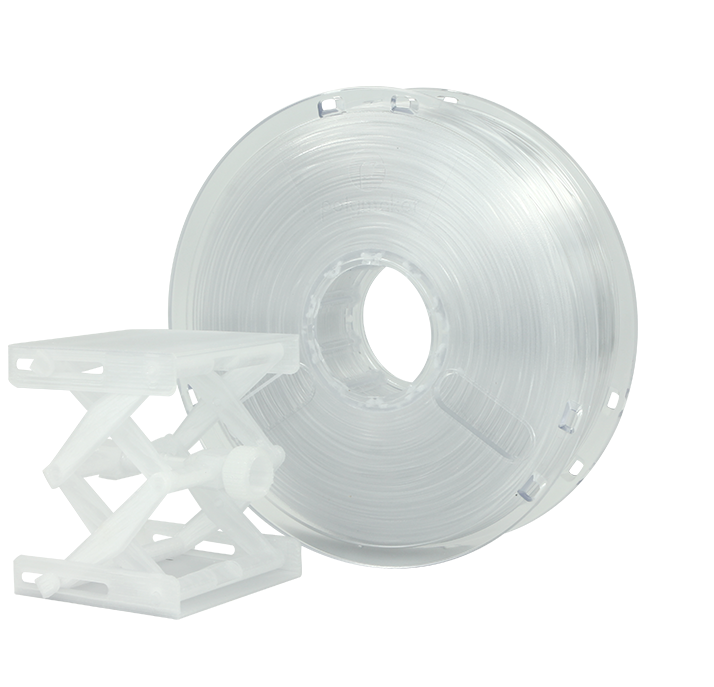

The first two members of this new material family are Polymaker PC-Plus™ and PC-Max™, which have been formulated and engineered to bring polycarbonate to the extrusion-based desktop 3D printers. They have achieved this by lowering the printing temperatures from 300 – 320ºC down to a moderate 250 – 270ºC, and significantly improving the warping resistance. Polymaker PC-Max™ further offers advanced mechanical properties—toughness, in particular—making it suitable for mechanically demanding applications.

The introduction of Polymaker PC is the result of Polymaker partnering with Covestro, formerly Bayer Material Science. Covestro, which provided the raw polycarbonate resins for Polymaker PC, is a worldwide supplier of innovative, sustainable and diverse high-tech polymer materials. Polymaker’s material scientists work closely with the Covestro team to enhance the formulation of the polycarbonate 3D filament to imbue it with unprecedented properties and functionalities for 3D printing.

“Covestro’s expertise, portfolio of products and industry leadership will be invaluable to our mission to provide the industry with the best materials with the performance, reliability and safety that will inspire our customers and expand our product portfolio,” said Dr. Xiaofan Luo, CEO of Polymaker.

Echoing this enthusiasm was Tim Efthimiady, Senior Vice President of the Polycarbonate Business Unit of Covestro: “We see the integration of our high-tech polymer materials in the field of 3D printing as a means to drive next-generation design and production solutions. We are very excited to work with Polymaker as we enter this burgeoning industry.”

Some of the key advantages of Polymaker PC compared to existing 3D printing materials are:

Heat Resistance: Unlike projects made with PLA or ABS material, those made with Polymaker PC will withstand temperatures of well over 100 °C. This makes it ideal for lighting, engineering, and practically any device or part that requires good structural stability when exposed to heat.

Excellent Mechanical Properties: being one of the most widely used engineering plastics in the world; PC has an excellent reputation for mechanical properties. Polymaker PC inherits these qualities while being fully compatible with desktop 3D printing. Parts made with Polymaker PC show much improved mechanical strength under almost all different deformation modes. Polymaker PC-Max further provides excellent impact resistance and toughness.

Post-Processing Capabilities: Polymaker PC can easily be post processed by sanding, coating, or other methods to suit the users’ functional needs.

Additional functional properties include intrinsic flame retardance, optical clarity, and resistance to chemicals and solvents. Polymaker will continue to develop new functional 3D printing materials based on PC.

Polymaker PC-Plus™ (MSRP $39.99 per reel, or $46.99 bundled with a 8” x 8” BuildTak sheet) will be available in October on the Polymaker website and through Polymaker’s worldwide distributor network. Polymaker PC-Max™ will be available before the end of this year.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.