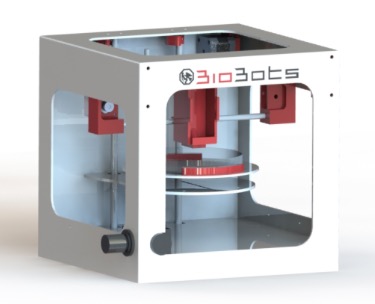

Following a partnership that has been established with Denver’s 3D Printing Store, researchers at the University of Denver started using the affordable BioBot 1 printer in their labs.

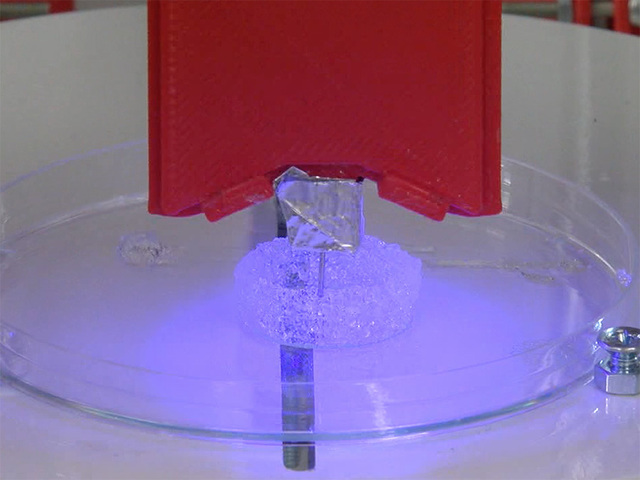

With their aim to one day be able to 3D bioprint artificial organs and tissue for patients, researchers have recently 3D printed a custom heart valve, with the design based on CT and MRI scans of the patient. The 3D printing process was completed in only 22 minutes.

“We’re really trying to take what’s become an accessible tool and use the most sophisticated thinking that we can to create something that will benefit all people,” explained research assistant and Denver University graduate Ben Stewart.

In order to be able to implant the valve inside a human body it would need to be placed inside a bioreactor, so the human cells attach to the scaffold structure that slowly dissolves afterwards.

While the lab has still a long way to go before the bioprinted valves could be used in humans, the approach would significantly reduce the invasive procedures performed on children, as it would grow with them.

Dr. Ali Azadani, Director of the DU Cardiac Biomechanics Lab further explains: “That [prosthetic] valve cannot grow as the child grows. So those patients typically need to go through multiple surgeries for their aortic valve. That’s very invasive, and that’s not the best approach. By designing tissue engineered valves, we can implant a valve in the heart that can grow with the child.”

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.