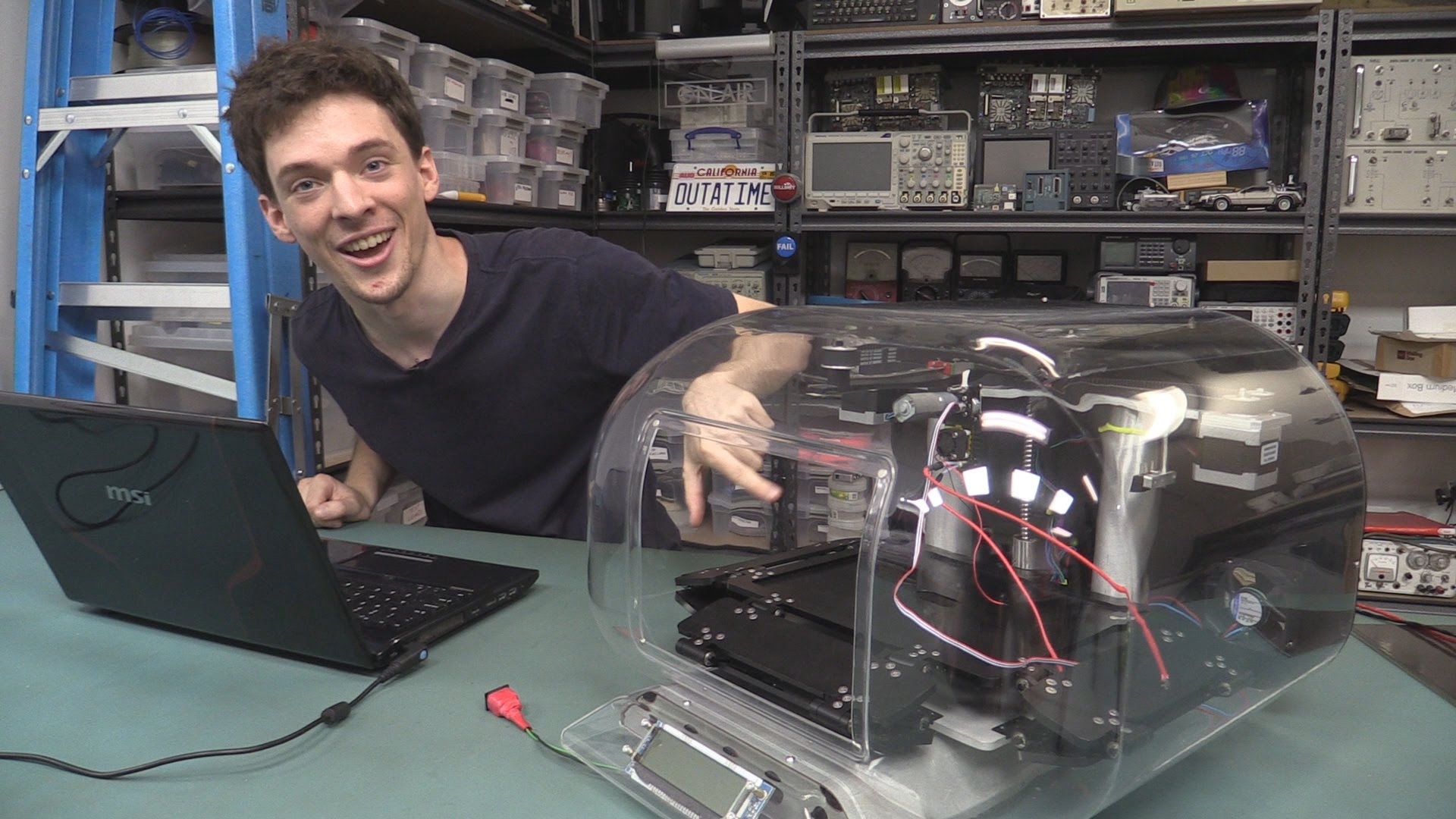

David from EEVblog designed a FDM/FFF 3D printer from ground up.

Its main purpose is prototyping and like a regular printer it is supposed to be put on a shelf. The project is David´s Capstone, that is something like his thesis. He designed everything completely from the ground up – from the controller and the software that runs on the controller to the chassis and the print bed, which is based on a Sarrus linkage. The bed has hinges on all four sides, so it only needs one motor to control the height and always stays levelled.

Check out the project here:

Unfortunately there are no plans to commercialise the rPrint at this time.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.