Solidscape, manufacturer of high precision 3D printers for direct manufacturing applications, and LSR’s Design Studio, announced a disruptive new prototype processes that will speed time to market.

By combining Solidscape’s high precision printing with LSR’s silicone or metal mold making process, prototypes can be created in less than two weeks, compared to the typical five to six weeks needed to create most new plastic or metal parts.

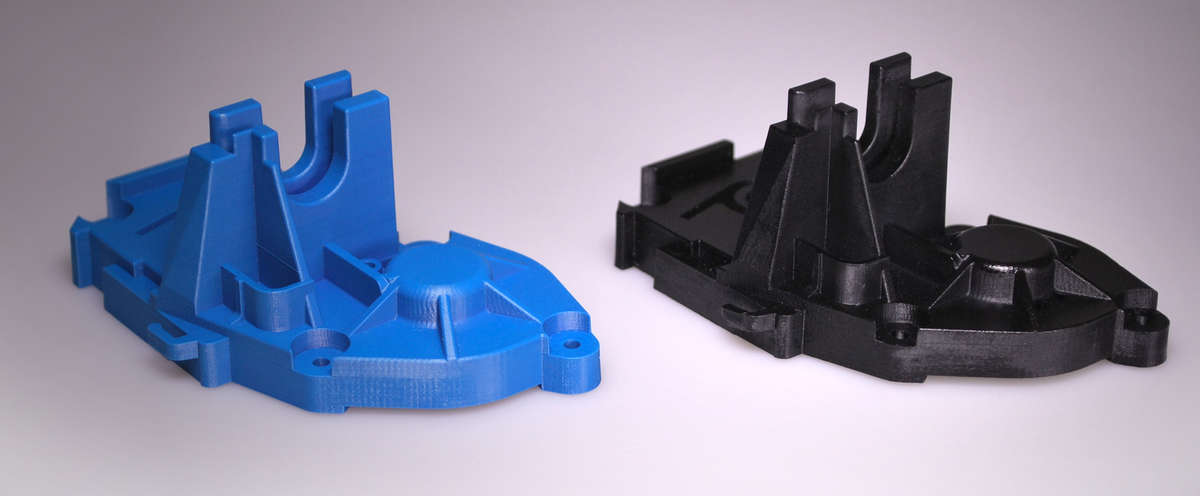

The process is unlike anything currently in the market and starts with Solidscape’s unique printing process, which is both additive and subtractive in nature. Printing at a resolution of 5000 dpi, Solidscape creates beautifully printed wax patterns that do not require hand finishing. The prototyping experts at LSR, a wireless product development company, can go directly to silicon tooling or to cast metal parts without the traditional tedious hand finishing of rapid prototype parts.

“We’re excited to collaborate with LSR on this new venture and to take rapid prototyping to the next level,” said Fabio Esposito, Solidscape President. “With this new disruptive process, users can now go directly from machine to molding, expediting the time it takes to go to market.”

“We compressed our product development process considerably on a recent program. We’ve gone from weeks of machining time and $4,000 per set of metal parts, to under two days and $200. This was earth shaking for us as well our customer,” said Jim Hollister, 3D Lab Manager at LSR.

Earlier this year, Solidscape released the MAX2, a fully automated printer with an easy- to-operate touch screen that allows any skill level to effectively produce high-precision wax patterns. The company’s lost wax casting process allows users to reproduce layers as fine as six microns every time.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.