Italian filament producer TreeD announces the release of their new P-LENE polypropylene filament, created to address the issue of material functionality in 3D printing.

Already known for their architectural, mechanical, and biodegradable filament products, TreeD’s newest material is a premier addition to their well-received 3D printing materials. P-LENE is a polypropylene-based filament, which is a thermoplastic polymer that is widely used for its high resistance and rigidity. Now, those superior mechanical properties have been reformulated for use with 3D printing technology.

There are a number of advantages that accompany the use of 3D printing technology, from cost effectiveness to faster production times. But one area that the technology slightly lacks is in material functionality, which oftentimes fails to meet the strength and resilience of the injection molding process.

TreeD’s new polypropylene-based filament offers 95% of the material characteristics of an injection molded object, including high mechanical strength, toughness, wear proof, and chemical resistance. P-LENE was specifically formulated for 3D printing purposes, and is both easy to use and odorless. The TreeD team, which was born out of the plastic extrusion company SA2P Xtrusionplastics, spent over a year studying and developing the filament.

Use the Right Plate

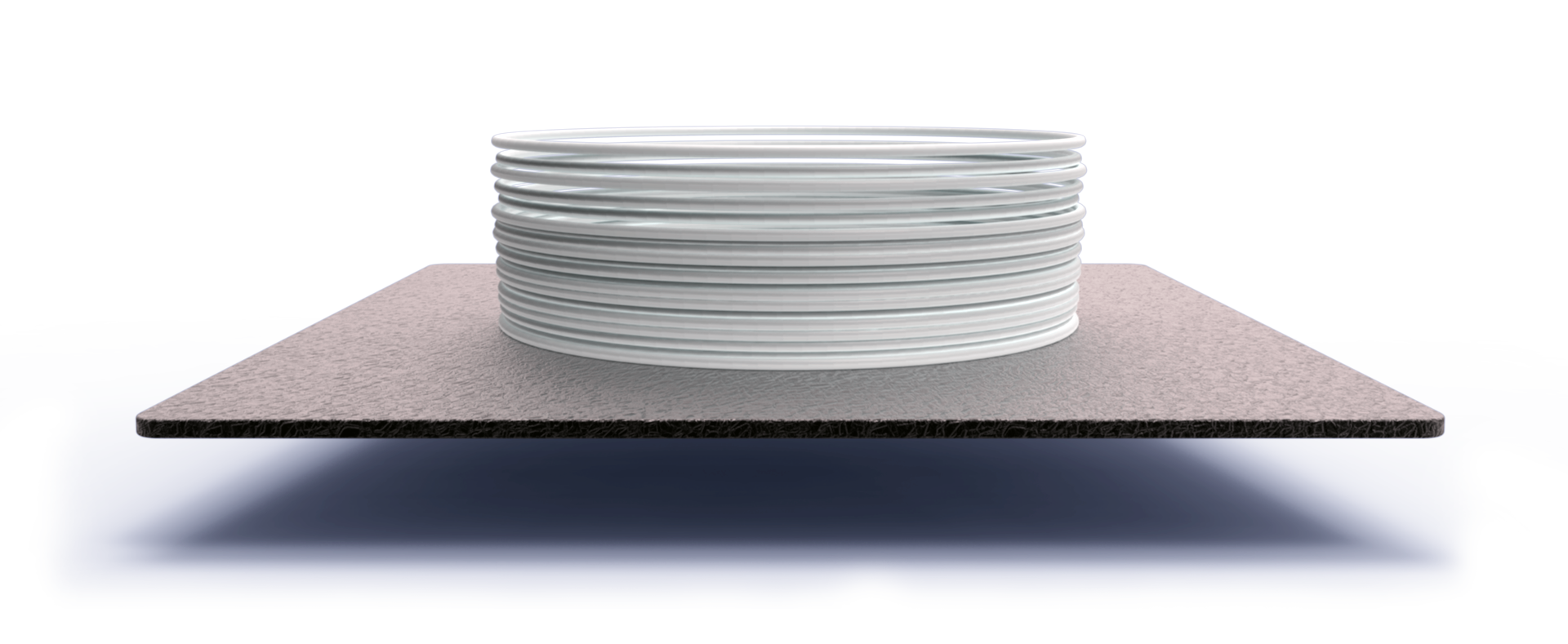

In order to maximize the performance of the P-LENE filament, TreeD also created the LENEPLATE buildplate. Developed specifically for the new polypropylene, the new print bed is made entirely out of solid metal eliminating the need for adhesive solutions. The patented buildplate is both durable and rigid, and the filament producer will tailor the LENEPLATE for any type of 3D printer.

Although the P-LENE filament is mechanically superior to many other standard materials, the print settings are quite normal. TreeD recommends a plate temperature of around 100°C, a nozzle temperature of 245°C, and a print speed of 60-70 mm/s. There are a number of great features that TreeD boasts about their latest material. Not only does it provide high impact and chemical resistance, it also prevents water absorption and doesn’t break under stress. The P-LENE is also recyclable, and can safely come in contact with food, skin, and pharmaceuticals.

By reformatting the widely used polypropylene polymer for 3D printing, TreeD is helping to push 3D printing technology to greater heights. By offering a filament that provides nearly the same strength as injection molding, more designers and manufacturers will be able to utilize 3D printing technology and expect superior material properties.

Find Out About Technical Polymers in the Doctor Filaments Guide

TreeD has also recently published the most complete and up to date guide for 3D printing materials, with is all there is to know about polymers in order to obtain the best results with 3D Printing. The compact Doctor Filaments, Guide for 3D Printing Materials intends to provide information for the optimal use of polymer-based filaments produced by us in the 3D printing industry.

Through this information, the company hopes to provide all of the necessary information needed to choose the ideal material required for the specific application. This guide will lay out specific characteristics of the most widely used polymers in the industry, offering a quick and comprehensive look at each 3D printing material.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.