TRUMPF, manufacturer of machine tools, lasers and electronics, will be introducing new metal 3D printers at the upcoming formnext trade fair.

The company has recently established a new division at its headquarters in Ditzingen, Germany. Their new additive manufacturing machines use Laser Metal Fusion (LMF) as well as Laser Metal Deposition (LMD) technology. TRUMPF has teamed up with Italien manufacturer of laser systems, Sisma, for their range of new 3D printing machines, that use laser technology to produce parts from metal powders.

“The introduction of these new 3D printers is an essential first step, since additive manufacturing will not only supplement production techniques in the future, but will also exert a formative influence on them,” explains Dr.-Ing. E.h. Peter Leibinger, Head of TRUMPF Laser- und Systemtechnik GmbH. “Market demand for industrial 3D printers for metal components is growing – and TRUMPF is the world’s only manufacturer to offer all the pertinent laser technologies from one source. Leibinger adds: “No matter whether you are dealing with injection nozzles, turbine blades, tools or even medical implants – with our broad range of technology we are offering the best solution for virtually every application.”

November 18, 2015 – Update: TRUMPF unveils new metal 3D printers at formnext

At the Formnext trade fair in Frankfurt, TRUMPF is introducing new machines and equipment for the additive manufacturing of metal parts. Of particular interest is the new laser metal fusion (LMF) process. Together with laser metal deposition (LMD) technology, which TRUMPF established 15 years ago and has continuously improved since that time, TRUMPF is the world’s only manufacturer to have all the pertinent laser technologies for industrial 3D printing in its program. LMF and LMD – TRUMPF offers both processes.

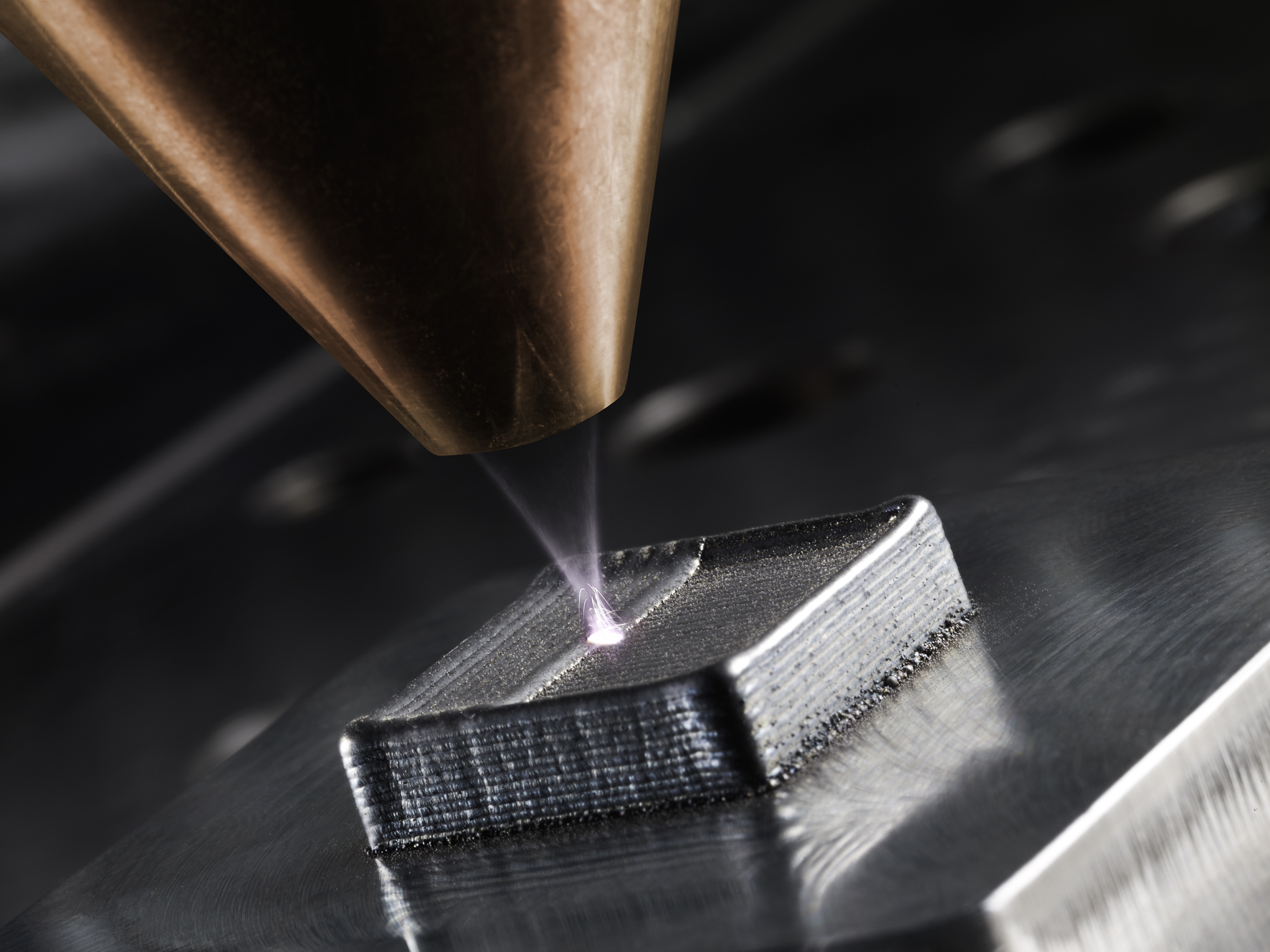

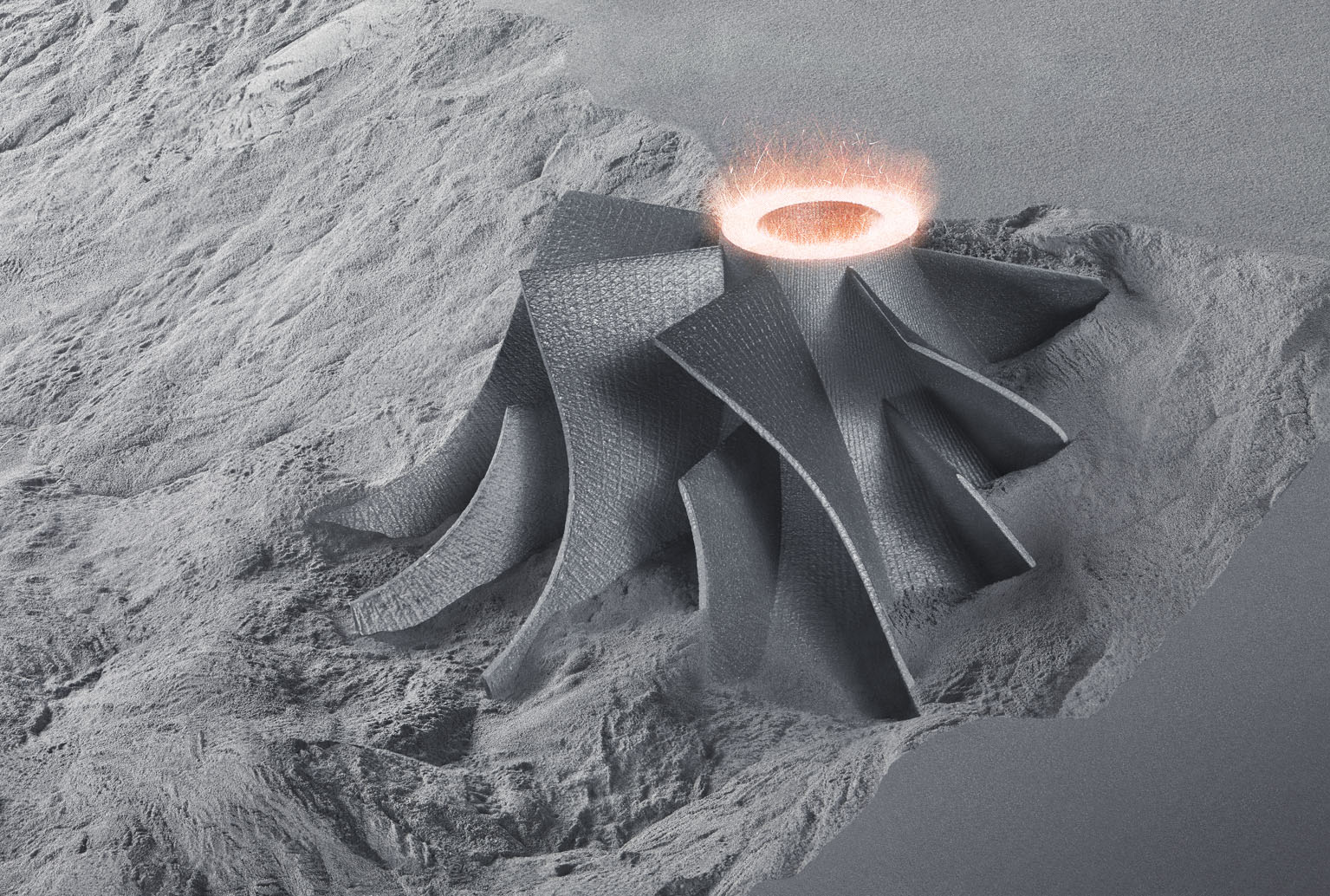

The principle of additive manufacturing is more than enticing. Laser and metallic powder build any desired component, based on data supplied directly by a CAD program. In LMF systems the component is created, layer by layer, from a bed of finely divided powder. This technology is suitable especially for parts that are complex in their geometry – such as those with internal channels and hollow spaces, and for economical manufacture of individual parts or short production runs.

TruPrint: 3D printer with new LMF technology

With the new TruPrint 1000 LMF machine, TRUMPF has set its sights on exactly these applications. The compact model appeals to both novices and those experienced in using this technology. It can generate parts that are a maximum of 100 millimeters in diameter and 100 millimeters tall. The user interface, optimized for simplified touch screen control, steps the operator intuitively through the individual phases in the process. All the components are integrated into the compact housing of the TruPrint 1000: the laser, optics, process enclosure, filter unit and control cabinet. The fascinating part actually takes place in the process enclosure, where the supply cylinder, construction chamber and overflow receiver are all aligned next to each other. The supply cylinder provides capacity for up to 1.4 liters of stainless steel, tool steel, aluminum or another weldable material in powdered form. As for the process itself: The so-called coating mechanism transfers powder from the supply cylinder to the construction chamber. Then the 200-watt laser fuses the first layer of powder, corresponding to the contour of the part. In the next step the construction chamber is lowered and the excess powder lands in the overflow receiver. This procedure is repeated until the part is completely finished. At every return to the supply cylinder, a clever mechanical design tilts the coating mechanism slightly. Thus it can retract relatively quickly, without colliding with the powder bed or the part generated up to that point. In order to avoid oxide formation, and thus the risk of fire, the entire process takes place inside the enclosure, blanketed by protective gas, and at an oxygen content of 0.1 percent.

In addition to the compact 1000 model, TRUMPF is also unveiling at the Formnext a prototype of the TruPrint 3000. With this larger model, also utilizing LMF technology, parts measuring up to 400 millimeters in height and 300 millimeters in diameter can be generated for industrial manufacturing. To ensure that the process is robust and the quality of the parts stays high, the process enclosure in the 3000 model is tempered to as much as 500 degrees Celsius.

A new LMD package: applying great volumes at high synthesis rates

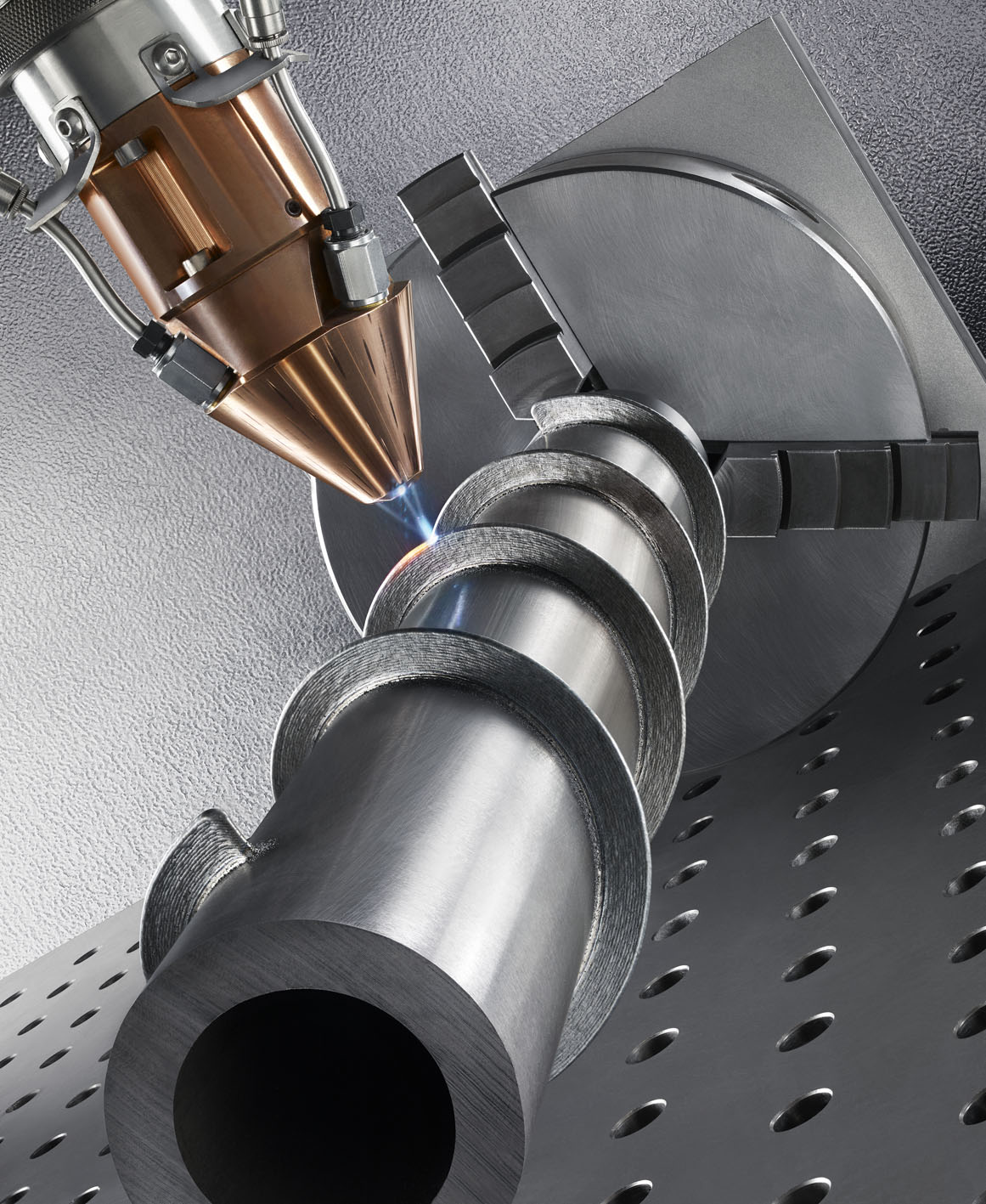

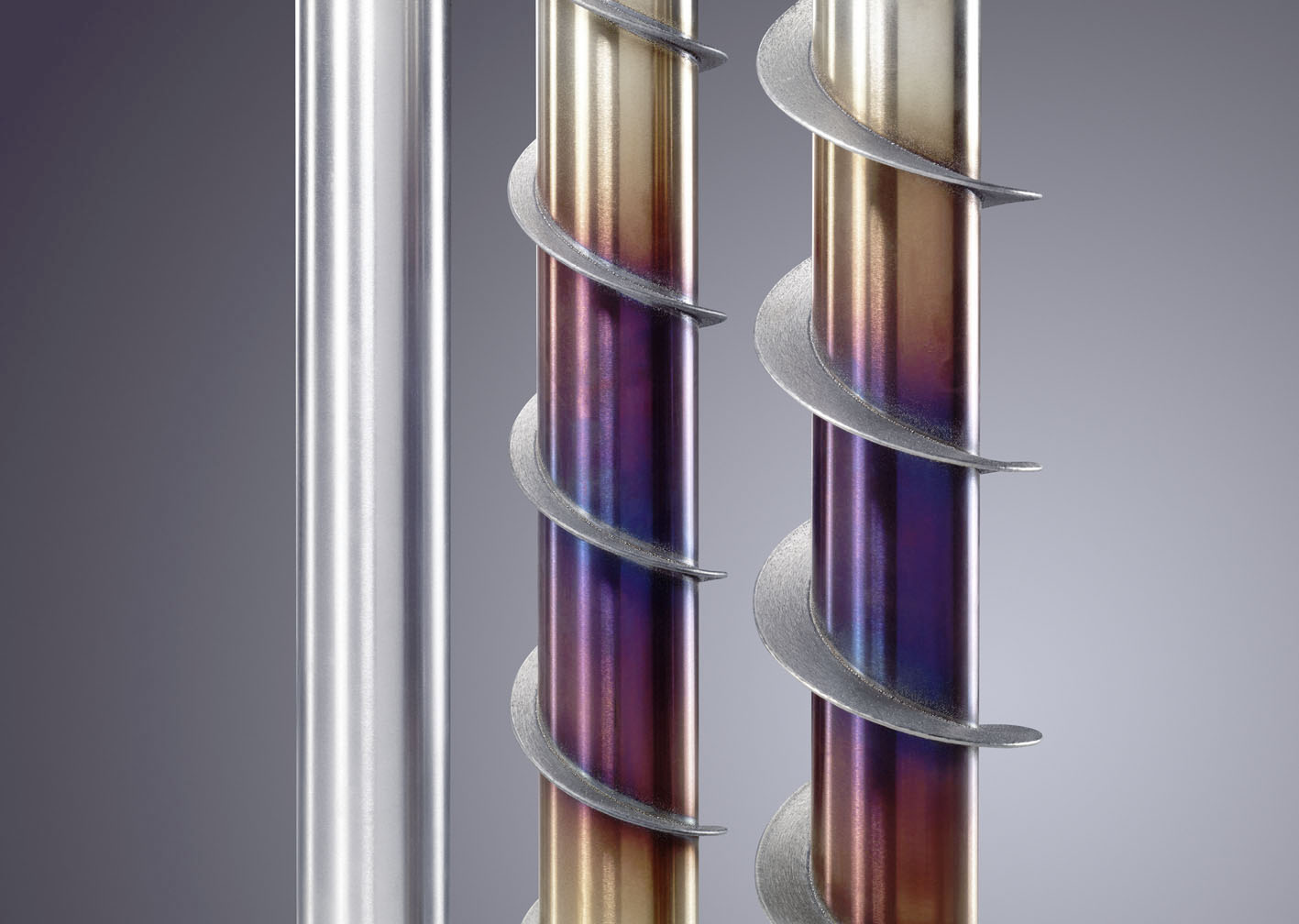

TRUMPF has also continued the optimization of its LMD technology and is presenting new solutions at the Formnext. These are suitable especially for adding volume and structures to existing parts. One example is adding a bolting flange to a pipe. In LMD systems, the laser forms a melt pool on the surface of a component and fuses the powder – applied simultaneously and coaxially – so as to create the desired shape. Consequently, a layer of beads welded one to another is created. Many layers together result in a body which can expand in any direction.

The great advantage of LMD technology is that the engineering required for the system is mature.

Thus, depending on the specifics of the application, With its new portfolio of technologies and products, TRUMPF is now offering its customers the complete package – the laser beam source, machine, powder, services and application consulting – from a single source.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.