Korean researchers at the RDA and Hallym University have developed a new bio 3D silk printing system to create orthopaedic implants.

Silk is a natural protein fibre composed mainly of fibroin and produced by certain insect larvae to form cocoons. Due to its excellent biocompatibility fibroin has been frequently used to produce medical equipment.

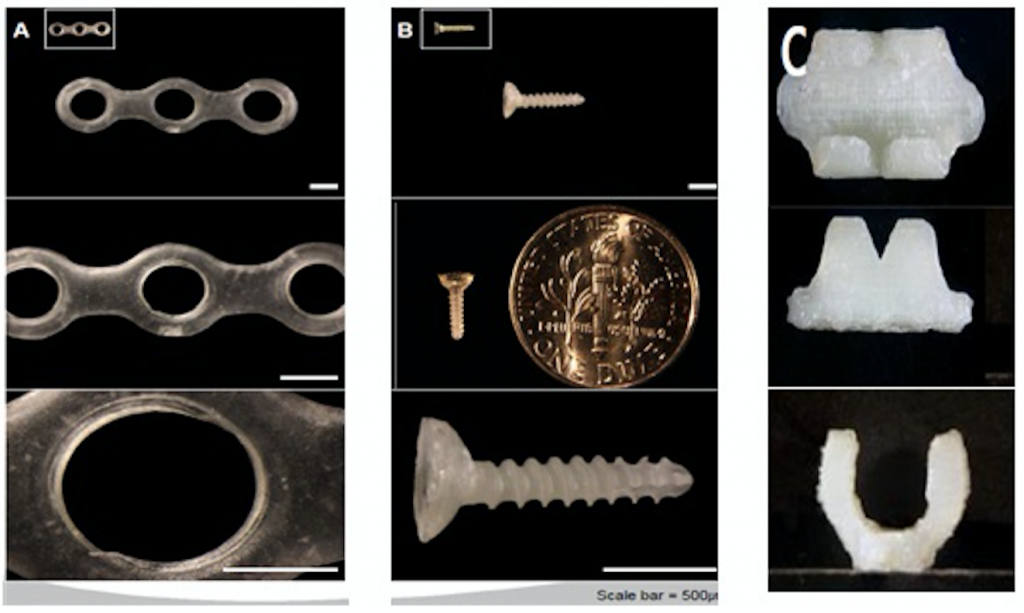

The research team has developed a 3D printable silk ink to successfully create implants that help stabilise and support broken bones, including plates, screws and clips. Traditionally, these implants are made from metals such as stainless steel or titanium alloy, however further surgery is required to remove them. Alternatively, synthetic biodegradable polymer can be used, which comes at higher costs and lacks stability.

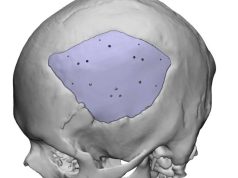

The new bioprinting ink allows to combine stability with biodegradation, with production cost of approximately half of that of synthetic polymer. Moreover, 3D printing enables for the production of custom, patient-specific shapes that can also be used for curved areas like the skull and cheekbones.

So far tests on animals proved to be effective, with no signs of inflammation or foreign body reactions. An RDA official said: “Once the technology becomes commercialized, it will allow for the production of a greater variety of biocompatible silk medical equipment, which will help improve national health while developing Korea’s sericulture industry.”

Subscribe to our Newsletter

3DPResso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.