On his YouTube channel, Briton Robert Murray-Smith presents a simple compressed air motor that he produced using a 3D printer. He was inspired by a steam engine project by YouTuber “Nouly”, which also primarily relied on 3D printing.

According to Murray-Smith, additive manufacturing does not enable high-quality steam engines, but it does enable compressed air engines. He therefore modified the original 3D model from “Nouly” and adapted it as a simple single-cylinder engine for compressed air.

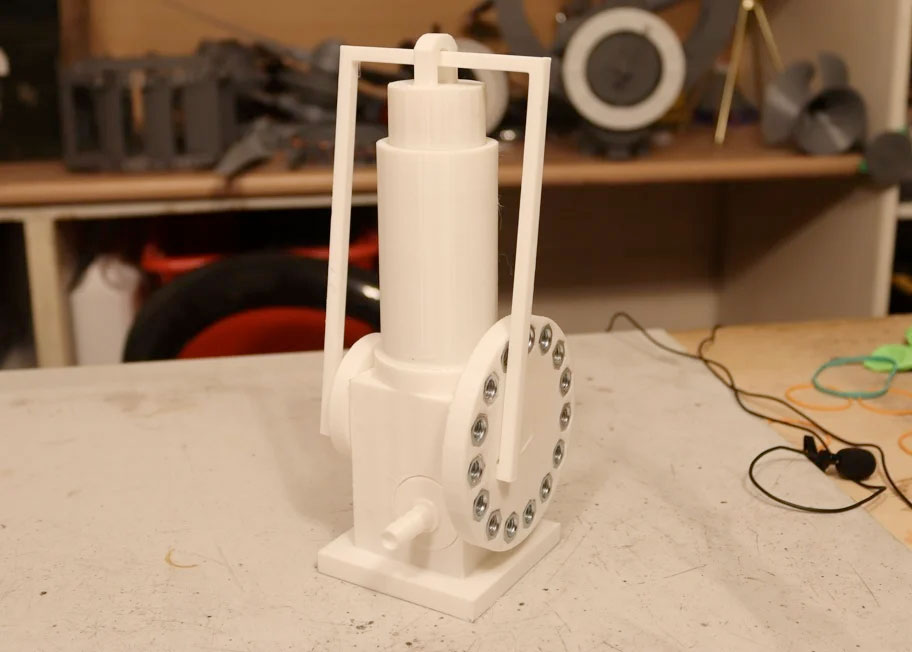

The result makes do with very few components: The cylinder housing, piston, connecting rod and flywheel only need to be plugged and glued together. According to Murray-Smith, the engine is therefore ideal for beginners without extensive workshop equipment. To increase the centrifugal force, he added separate weight to the flywheel in the form of nuts.

In a test run, Murray-Smith manually blew compressed air into the engine to get it running. This showed that the mini motor accelerates well despite the very low pressure. According to the YouTuber, this underlines the potential for mobile use with small compressed air tanks.

However, according to Murray-Smith, many conventional combustion engines or steam engines can also be converted to compressed air quite easily. It is often only necessary to replace the valve with a slide valve.

Murray-Smith makes the 3D print files available free of charge on Thingiverse.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.