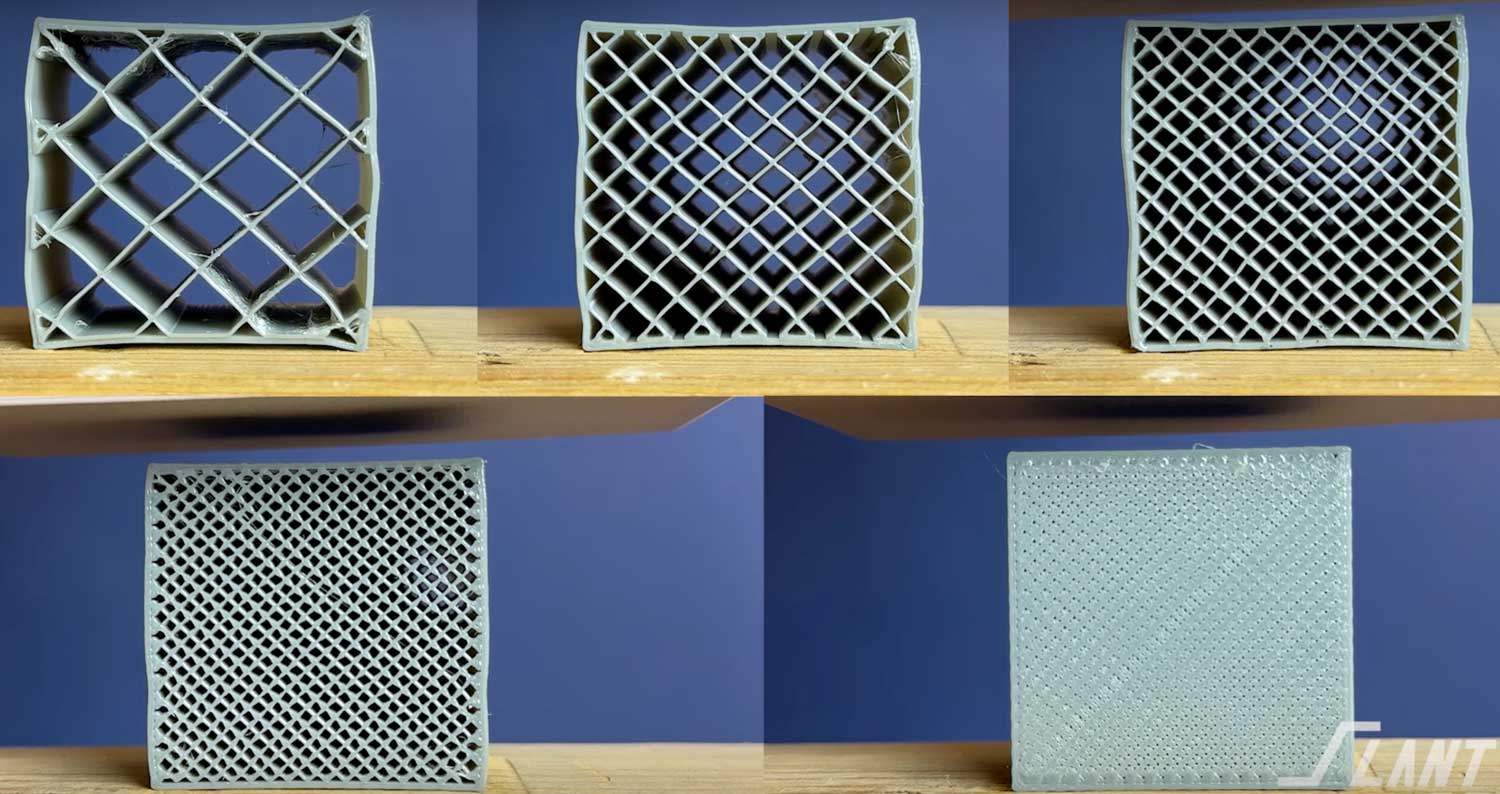

As Slant 3D shows in their YouTube video, the material behavior of TPU filament in 3D printing can be significantly influenced by the choice of infill pattern. The same TPU filament with 95A hardness was used for various test cubes with 10%, 20%, 30%, 50% and 100% infill.

The cubes were then subjected to a compression test in which a force of up to 6000 newtons was exerted on them. It was found that the stiffness and maximum compressive strength increased considerably with increasing filling. While the 10%-filled cube could only bear 50 Newtons, the 50%-filled cube could withstand 2000 Newtons.

According to Slant 3D, this experiment impressively demonstrates that the mechanical properties of TPU parts can be adjusted within wide limits via the degree of filling – from very flexible and elastic to a hardness similar to that of car tires. This adaptability makes it possible to adapt the parts precisely to the application.

Subscribe to our Newsletter

3DPresso is a weekly newsletter that links to the most exciting global stories from the 3D printing and additive manufacturing industry.